- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SARTRE

-

Model Number:

-

Colorful Coating Thread Milling Cutter

-

Brand:

-

SARTRE

Quick Details

-

Material:

-

Tungsten Cobalt Alloy

-

Coating:

-

Other

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

SARTRE

-

Model Number:

-

Colorful Coating Thread Milling Cutter

-

Brand:

-

SARTRE

Company Summary

Product Description

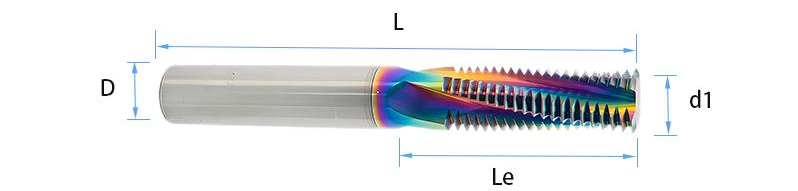

Product Specification Details:

|

No.

|

Size

|

d1

|

Le

|

D

|

L

|

|

1

|

M3*0.5

|

2.35

|

6

|

4

|

50

|

|

2

|

M4*0.7

|

3.15

|

8

|

4

|

50

|

|

3

|

M5*0.5

|

4

|

10

|

6

|

50

|

|

4

|

M5*0.75

|

4

|

10

|

6

|

50

|

|

5

|

M5*0.8

|

4

|

10

|

6

|

50

|

|

6

|

M6*0.75

|

4.8

|

12

|

6

|

50

|

|

7

|

M6*1.0

|

4.8

|

12

|

6

|

50

|

|

8

|

M8*0.5

|

6

|

16

|

8

|

60

|

|

9

|

M8*0.75

|

6

|

16

|

8

|

60

|

|

10

|

M8*1.0

|

6

|

16

|

8

|

60

|

|

11

|

M8*1.25

|

6

|

16

|

8

|

60

|

|

12

|

M10*1.0

|

8

|

21

|

10

|

60

|

|

13

|

M10*1.25

|

8

|

21

|

10

|

60

|

|

14

|

M10*1.5

|

8

|

21

|

10

|

60

|

|

15

|

M12*0.5

|

10

|

24

|

12

|

75

|

|

16

|

M12*0.75

|

10

|

24

|

12

|

75

|

|

17

|

M12*1.0

|

10

|

24

|

12

|

75

|

|

18

|

M12*1.5

|

10

|

24

|

12

|

75

|

|

19

|

M12*1.75

|

10

|

24

|

12

|

75

|

|

20

|

M14*1.0

|

12

|

28

|

14

|

75

|

|

21

|

M14*1.5

|

12

|

28

|

14

|

75

|

|

22

|

M14*2.0

|

11.6

|

28

|

14

|

75

|

|

23

|

M16*1.5

|

14

|

32

|

16

|

100

|

|

24

|

M16*2.0

|

13

|

32

|

16

|

100

|

|

25

|

M18*2.5

|

14.8

|

38

|

18

|

100

|

|

26

|

M20*1.5

|

16

|

38

|

20

|

100

|

|

27

|

M24*3.0

|

16

|

42

|

24

|

100

|

Product Parameter:

|

Coating Introduction

|

|

|

|

|

|

|

||||||

|

Endmill Grade

|

Coating Name

|

Color

|

Hv

|

μm

|

Friction Coefficient

|

The Max ℃

|

||||||

|

HRC45 coating

|

AlTiN

|

black

|

3300

|

1-4

|

0.7

|

850℃

|

||||||

|

HRC55 coating

|

TiSiAlN

|

bronzed

|

3400

|

1-4

|

0.7

|

900℃

|

||||||

|

HRC60 coating

|

AlCrSiN

|

black

|

4000

|

1-7

|

0.35

|

1100℃

|

||||||

|

HRC65 coating

|

nACo 3 Blue

|

blue

|

4500

|

1-7

|

0.45

|

1200℃

|

||||||

|

Stainless Steel coating

|

nACo 3 Gold

|

golden

|

4500

|

1-7

|

0.55

|

1200℃

|

||||||

|

Carbide Material Introduction

|

|

|

|

|

|

|

|

|

||||||||

|

Endmill Grade

|

Material Grade

|

Grain

|

Introduction

|

|

|

|

|

Application

|

||||||||

|

HRC45 carbide material

|

YL10.2

|

0.6μm

|

YL10.2 is tungsten carbide powder with 89.7% WC and 10% cobalt powder, and has high toughness and wear resistance.

|

|

|

|

|

Suitable for General Steel

|

||||||||

|

HRC55 carbide material

|

K30

|

0.5μm

|

K30 is ultra fine grain and containes Ni and Cr element, which provides high strength and good toughness.

|

|

|

|

|

General Steel, Stainless Steel, cast iron

|

||||||||

|

HRC60 carbide material

|

WF25

|

0.4μm

|

WF25 is 0.4micron ultrafine carbide powder and provides very high toughness and wear resistance.

|

|

|

|

|

High Hard Material, steel, cast iron, etc

|

||||||||

|

HRC65 carbide material

|

GU25UF

|

0.4μm

|

GU25UF is 0.4micron powder with 12% cobalt and has very high toughness and wear resistance.It is the most suitable for hard

cutting.

|

|

|

|

|

Titanium Alloy, High-temperature Alloy, Harden material, etc

|

||||||||

|

Stainless Steel material

|

WF25

|

0.4μm

|

WF25 is 0.4micron ultrafine carbide powder and provides very high toughness and wear resistance.

|

|

|

|

|

stainless steel

|

||||||||

Product Feature:

1.Special cutting edge and DLC coating, so as to achieve high precision, long life processing.

2. Bow R edge disperses cutting resistance to inhibit cutting edge wear.

3. Cone of the product, copying processing, even if the use of the entire cutting edge can also achieve high precision, finish surface roughness is good.

4. Smooth and sharp cutting edge can obtain ideal wear resistance and adhesion resistance.

2. Bow R edge disperses cutting resistance to inhibit cutting edge wear.

3. Cone of the product, copying processing, even if the use of the entire cutting edge can also achieve high precision, finish surface roughness is good.

4. Smooth and sharp cutting edge can obtain ideal wear resistance and adhesion resistance.

|

Hardness

|

Material

|

Coating

|

Coating color

|

Thread Angle

|

|

HRA91.3

|

WF25

|

DLC

|

Colorful

|

60°

|

|

Suitable Material For Processing

|

|

|

|

|

||||

|

7075、6061、6063 Aluminum Profile

|

Aluminium Die Casting

|

Copper

|

Plastic

|

Bakelite Plate

|

||||

Product Display

Our Services

Hot Searches