- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

CUSTOMIZED

-

Power:

-

3+0.37, 4+0.55kw

-

Dimension(L*W*H):

-

4000*1500*1700mm

-

Weight (KG):

-

1200

-

Name:

-

Alfalfa Crop Straw Wood Chips Sawdust Biomass Dryer Machine

-

Keywords:

-

Biomass Sugarcane Waste Drying Machines

-

Raw material:

-

river sand,silica sand,limestone,slag,coal ash,sawdust

-

Advantage:

-

High Working Effiency

-

Package:

-

Standard Package

-

Color:

-

Customer Demand

-

Weight:

-

1200kg

-

After Warranty Service:

-

Video Technical Support Maintenance Guidance

Quick Details

-

Type:

-

Rotary Drying Equipment

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

JINGYING

-

Voltage:

-

CUSTOMIZED

-

Power:

-

3+0.37, 4+0.55kw

-

Dimension(L*W*H):

-

4000*1500*1700mm

-

Weight (KG):

-

1200

-

Name:

-

Alfalfa Crop Straw Wood Chips Sawdust Biomass Dryer Machine

-

Keywords:

-

Biomass Sugarcane Waste Drying Machines

-

Raw material:

-

river sand,silica sand,limestone,slag,coal ash,sawdust

-

Advantage:

-

High Working Effiency

-

Package:

-

Standard Package

-

Color:

-

Customer Demand

-

Weight:

-

1200kg

-

After Warranty Service:

-

Video Technical Support Maintenance Guidance

Product Description

Dryer is a new type small multi-functional dryer, suitable for various drying operations,and four feet can install mobile wheel, which can adapt to a various working environment.The main models are 300, 500, 1000, 2000 and 4000, and can accept different models customized according to customer demand, Our company senior engineer track and guide the whole process , in order to meet customer request!

Product Parameter

|

Model

|

Power(KW)

|

Heating power(KW)

|

Capacity(KG)

|

Dimension(MM)

|

Weight(KG)

|

||||

|

JY-300R

|

3+0.37

|

30-40

|

300

|

3200*1250*1450

|

600

|

||||

|

JY-500R

|

3+0.37

|

40-50

|

500

|

4200*1250*1500

|

800

|

||||

|

JY-1000R

|

4+0.55

|

60-80

|

1000

|

4800*1500*1700

|

1200

|

||||

|

JY-2000R

|

7.5+0.75

|

80-100

|

2000

|

6000*1800*2100

|

1800

|

||||

|

JY-3000R

|

11+1.1

|

120-150

|

3000

|

7200*1800*2100

|

3000

|

||||

|

JY-5000R

|

11+1.5

|

150-180

|

5000

|

9000*2100*2300

|

4500

|

||||

|

Remarks

|

Above data is just for reference.Different materials moisture ,capacity request and heating source,the parameter may has subtle gap difference ,Please refer to the actual situation.

|

|

|

|

|

||||

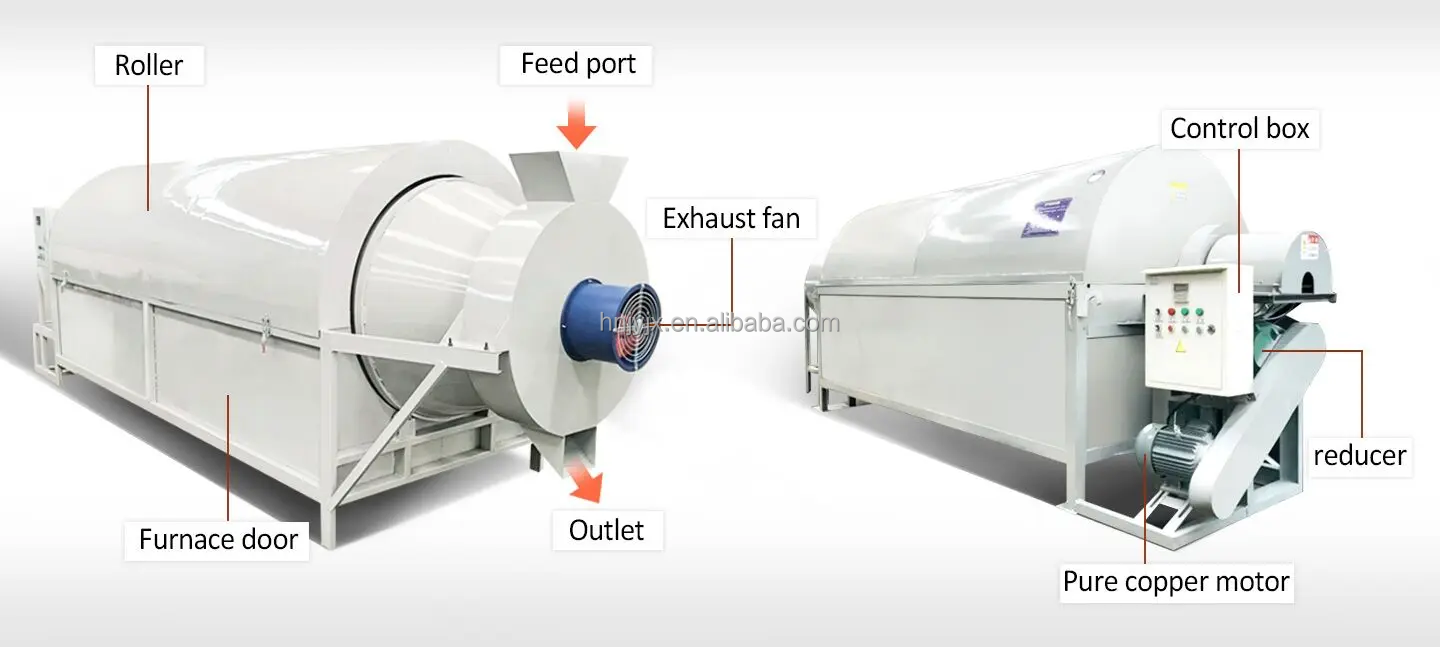

Details Images

Multifunctional tumble dryer

The structure of the drum dryer is evenly heated and easy to control. The motor is equipped with a forward and reverse controller, a temperature regulator, and a material port can realize material feeding and discharging. The machine adopts a drum horizontal structure, the drum is heated evenly, and has the function of heat preservation, automatic rotation, automatic stir frying, automatic pot out, the drum rotates continuously during work, so that the material is stirred up and down, left and right, front and back, three-dimensionally, without There will be sticking phenomenon. It is necessary to press the forward and reverse switch, the motor will drive the drum to reverse, and the feed will be out of the pot, which is fast, easy and effortless, and the automatic temperature control device can be operated practically, and the heating efficiency is good.

The machine can be widely used in river sand, sludge, coal slime, sawdust, rice, corn, wheat, soybean, rapeseed, seed grain, grass seed, sand, tofu, chicken manure, organic fertilizer, feed, distiller's grains, vinegar grains and other fields.

Scope of application

It is suitable for all roasted seeds and nuts, health care raw materials processing,condiment and raw material processing, fried chestnuts, fried peanuts, fried melon seeds, and can also dry fertilizers, cinders, wood chips and other materials.

ADVANTAGES

1. It can be widely used in drying materials in the fields of river sand, sludge, coal slime, sawdust, sand, bean curd

residue,chicken manure, organic fertilizer, feed, Chinese medicinal residue, distiller's grains, vinegar grains and other fields;

2. Using hot air as drying medium and adopting circulating drying process, the material receives uniform and sufficient heat and precipitation and has good quality after drying;

3. The heating system of the dryer is more advanced, and the material is dried by the heat energy after conversion;

4. Equipped with automatic on-line temperature measurement and humidity measurement device, the degree of automation is greatly improved, and the drying uniformity is high;

5, can automatically control the working process, automatic stop, simple operation, labor saving, greatly reduce labor costs.

residue,chicken manure, organic fertilizer, feed, Chinese medicinal residue, distiller's grains, vinegar grains and other fields;

2. Using hot air as drying medium and adopting circulating drying process, the material receives uniform and sufficient heat and precipitation and has good quality after drying;

3. The heating system of the dryer is more advanced, and the material is dried by the heat energy after conversion;

4. Equipped with automatic on-line temperature measurement and humidity measurement device, the degree of automation is greatly improved, and the drying uniformity is high;

5, can automatically control the working process, automatic stop, simple operation, labor saving, greatly reduce labor costs.

Customer Site

Packing and Shipping

Hot Searches