- Product Details

- {{item.text}}

Quick Details

-

Lifting Weight:

-

1-4 t/h

-

Driven Type:

-

Electical

-

Name:

-

ton bulk bag discharger

-

Key Words:

-

big bag discharge machine

-

Application:

-

Transfer Materials

-

function:

-

1000kg FIBC bag discharger

-

Voltage:

-

110V 220V 230V 380V 400V 415V 440V 500V 600V 50HZ 60HZ

Quick Details

-

Warranty:

-

1 Year

-

Weight (KG):

-

1300

-

Place of Origin:

-

China

-

Lifting Weight:

-

1-4 t/h

-

Driven Type:

-

Electical

-

Name:

-

ton bulk bag discharger

-

Key Words:

-

big bag discharge machine

-

Application:

-

Transfer Materials

-

function:

-

1000kg FIBC bag discharger

-

Voltage:

-

110V 220V 230V 380V 400V 415V 440V 500V 600V 50HZ 60HZ

Machine description of

big bag unloading station

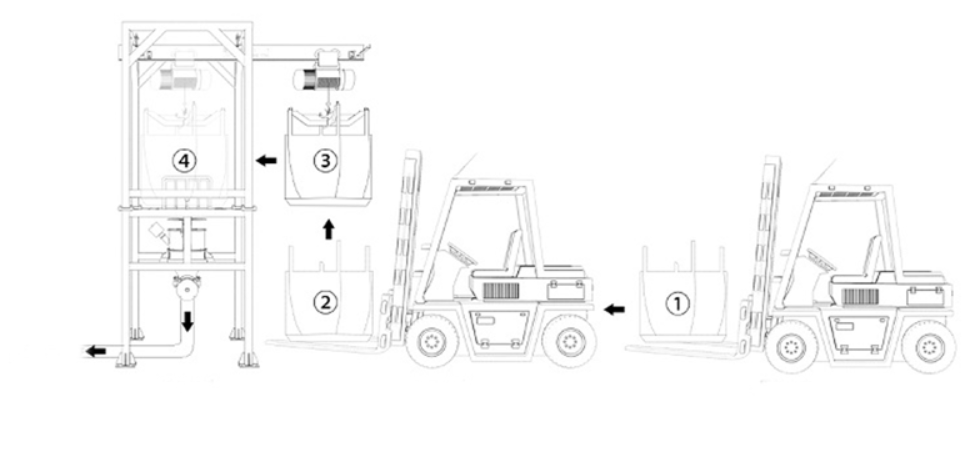

The working principle of ton bag unloader

Application of bulk bag dischargers

|

Model

|

Electric hoist power

|

Unloading Speed

|

Rotary valve power

|

Hight

|

Frame Material

|

|||||

|

CWTB

|

3 kw

|

1-4 t/h

|

0.75-1.5kw

|

4.6-4.9m

|

Carbon steel, 304,304L / 316L stainless steel

|

|||||

|

Customizable parts: conveying equipment (screw conveyor, vacuum feeder, pneumatic conveying system, etc.)

|

|

|

|

|

|

|||||

Closed production system to

prevent dust from flying

The overall height is between 2-5 meters

and customization is also acceptable

Driven telescopic filling tube

Screw conveyor

Connection system

Electric hoist

Xinxiang Chenwei Machinery Co., Ltd is a manufacturer of vibrating screens, centrifugal sifters, tumbler screens, gyratory screens and aluminum foil tape with well-equipped testing equipment and strong technical force. With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in mining, pharmacy, food, chemical, metal powder and other industries.