- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

GW

-

Model Number:

-

DN

-

Material:

-

Ductile Iron GGG450-12, ASTM A546

-

Usage:

-

Pipe Connection

-

Range of Sizes:

-

DN50-1800mm

-

End Connection:

-

Flange

-

Lining:

-

Cement Mortar Lining

-

External Coating:

-

Zinc-Rich Coating and Bitumen Painting

-

Gasket Material:

-

SBR

-

Packing:

-

Wooden Case or Pallet

-

Brand:

-

GW

Quick Details

-

Technics:

-

Casting

-

Shape:

-

Equal

-

Head Code:

-

Square

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

GW

-

Model Number:

-

DN

-

Material:

-

Ductile Iron GGG450-12, ASTM A546

-

Usage:

-

Pipe Connection

-

Range of Sizes:

-

DN50-1800mm

-

End Connection:

-

Flange

-

Lining:

-

Cement Mortar Lining

-

External Coating:

-

Zinc-Rich Coating and Bitumen Painting

-

Gasket Material:

-

SBR

-

Packing:

-

Wooden Case or Pallet

-

Brand:

-

GW

Product Description

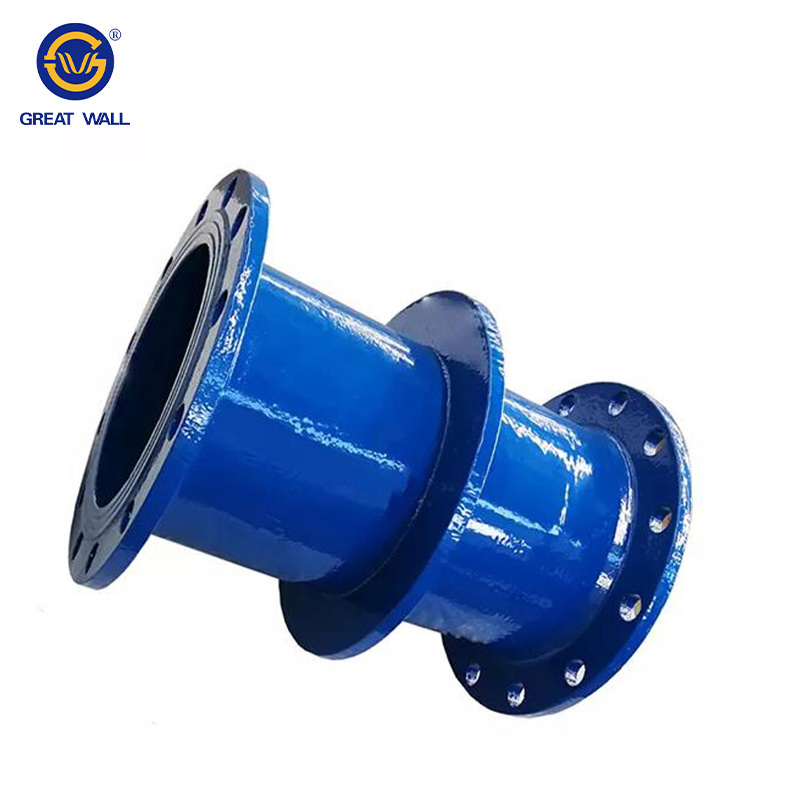

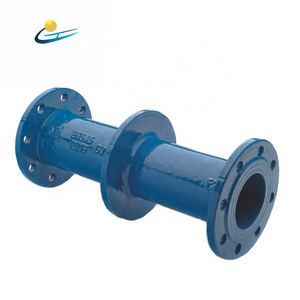

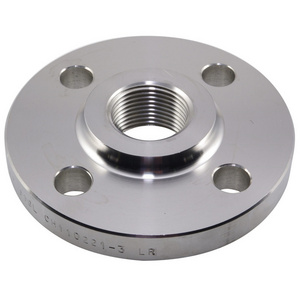

Our ductile iron pipe fittings

series including Double Socket Bend, Double Flange Bend, All Socket Tee, All Flange Tee, Double Flange Taper, Double Socket Taper, All Socket Cross, All Flange Cross, Double Flange Duckfoot Bend Elbow,

Double Flange Short Pipe, Collars,

Blind Flange and etc

Our ductile iron pipe fittings are widely used for water supply, drainage, sewage, irrigation industry .

Specification

Body: Ductile iron grade 500-7/450-12 in accordance with ISO 1083. COATING:cement mortal lining as per ISO4179 ,zinc primer and bitument painting according to ISO8179 epoxy (with WARS for epoxy powder) coated in blue, black, red or according to customers' requirements.

|

Range of Sizes

|

DN50-DN2000(2''-80'')

|

|

Flange Standard

|

PN10, PN16, PN25, PN40

|

|

Design Standard

|

ISO2531, BS EN545, BS EN598, EN12842, AWWA C110, AWWA C153 and etc

|

|

End Connection

|

Flange or Spigot Socket

|

|

Internal Coating

|

Cement Mortar Lining / Fusion Bonded Epoxy Coating

|

|

External Coating

|

Zinc-Rich Coating +Bitumen Painting / Fusion Bonded Epoxy Coating

|

|

Tensile Strength

|

>= 420 N/MM2

|

|

Elongation

|

>= 5%

|

|

Brinell Hardness

|

<= 250 HB

|

|

Pressure Test

|

DN80-300mm >=25bar, DN350-600mm >=16bar, DN700-1600mm>=10bar

|

Production Process

Hot Searches