- Product Details

- {{item.text}}

Quick Details

-

Ultimate Strength (≥ MPa):

-

195~315

-

Elongation (≥ %):

-

40%

-

Specification:

-

Any Size Can be Customised

-

Grade:

-

99.9% Pure Copper

-

Length:

-

0.3mm-2000mm, 0.3mm-2000mm

-

Wall Thickness:

-

0.1mm - 50mm, 0.025mm-0.6mm

-

Outside Diameter:

-

3mm - 360mm, 0.07mm-8.0mm

-

Place of Origin:

-

Colorado, United States

-

Product Name:

-

copper pipe

-

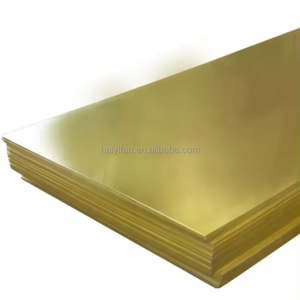

Material:

-

Copper Brass Bronze

-

Technique:

-

Cold Rolled Hot Rolled

-

Surface:

-

Polished

-

Hardness:

-

Hard

-

Connection Type:

-

Threaded

Quick Details

-

Type:

-

Customized

-

Cu (Min):

-

99.96%

-

Alloy Or Not:

-

Is Alloy

-

Ultimate Strength (≥ MPa):

-

195~315

-

Elongation (≥ %):

-

40%

-

Specification:

-

Any Size Can be Customised

-

Grade:

-

99.9% Pure Copper

-

Length:

-

0.3mm-2000mm, 0.3mm-2000mm

-

Wall Thickness:

-

0.1mm - 50mm, 0.025mm-0.6mm

-

Outside Diameter:

-

3mm - 360mm, 0.07mm-8.0mm

-

Place of Origin:

-

Colorado, United States

-

Product Name:

-

copper pipe

-

Material:

-

Copper Brass Bronze

-

Technique:

-

Cold Rolled Hot Rolled

-

Surface:

-

Polished

-

Hardness:

-

Hard

-

Connection Type:

-

Threaded

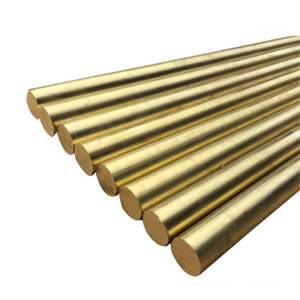

Copper tubes, also known as copper tubes, are pressed and drawn seamless tubes.

Copper tubes are lightweight, have good thermal conductivity, and have high low-temperature strength. Often used in the manufacture of heat exchange equipment (such as condensers, etc.). It is also used to assemble low-temperature pipelines in oxygen production equipment. Small-diameter copper pipes are often used to transport pressured liquids (such as lubrication systems, oil pressure systems, etc.) and pressure measuring tubes used as instruments.

|

Product Name

|

Copper Pipe

|

|

Application

|

Water Heater

|

|

Specification

|

4mm, 6mm, 8mm, 10mm, 12mm, 15mm, etc.

|

|

Grade

|

T1, T2, C1100, TU2, TP1, TP2, C1020, C1201, etc.

|

|

Length

|

2m, 3m, 4m, 6m, etc.

|

|

Wall Thickness

|

0.5m, 0.8mm, 1mm, 1.2mm, 1.5mm, 2mm, etc.

|

|

Outside Diameter

|

8mm, 10mm, 12mm, 15mm, 18mm, 28mm, 35mm, 42mm, etc

|

|

Model Number

|

T1, T2, C1100, TU2, TP1, TP2, C1020, C1201, etc.

|

|

Processing Service

|

Bending, Decoiling, Welding, Punching, Cutting

|

|

Shape

|

Round & Straight Pipe Copper Tube

|

|

Standard

|

ASTM, JIS, DIN, AISI, EN, GB, etc.

|

|

Color

|

Red

|

|

Material

|

T1, T2, T3, C1100, TU1, TP1, TP2, C1020, C1201, C1220, C11000, etc.

|

|

Element

|

Cu

|

|

Copper content

|

0.999

|

|

Density

|

7.83g/cm3

|

|

Thickness

|

0.5m, 0.8mm, 1mm, 1.2mm, 1.5mm, 2mm, etc.

|

|

Diameter

|

4mm, 6mm, 8mm, 10mm, 12mm, 15mm, 18mm, 22mm, 28mm, 35mm, 42mm, etc.

|

(1) General copper pipes: General copper pipes are used to transport low-pressure fluids. Made of Q195A, Q215A, Q235A steel. It can also be made of other mild steels that are easily weldable. Copper pipes need to undergo water pressure, bending, flattening and other experiments, and have certain requirements for surface quality. The delivery length is usually 4-10m, and delivery of fixed length (or multiple lengths) is often required. The specifications of copper pipes are expressed in nominal diameter (mm or inches). The nominal diameter is different from the actual diameter. According to the specified wall thickness, there are two types of copper pipes: ordinary copper pipes and thickened copper pipes. Copper pipes are divided into threaded and non-threaded ones according to the form of the pipe end. Two types of threads.

(2) Oxygen blowing copper pipe: It is used as a pipe for oxygen blowing in steelmaking. It is generally a small diameter welded copper pipe with eight specifications ranging from 3/8 inch to 2 inch. Made of 08, 10, 15, 20 or Q195-Q235 steel strip. In order to prevent corrosion, some are aluminized.

(3) Galvanized copper pipe: In order to improve the corrosion resistance of copper pipes, general copper pipes (black pipes) are galvanized. Galvanized copper pipes are divided into two types: hot-dip galvanizing and electric steel zinc. Hot-dip galvanizing has a thick zinc layer and electro-galvanizing has a low cost.

(4) Metric copper pipe: The specification is in the form of seamless pipe, and the welded copper pipe is expressed in outer diameter * wall thickness in millimeters. It is welded with tropical and cold strips of ordinary carbon steel, high-quality carbon steel or general low alloy steel. Or it can be made by hot-temperature welding and then cold drawing. Metric copper tubes are divided into general and thin-walled ones. They are generally used as structural parts, such as drive shafts, or to transport fluids. Thin-walled copper tubes are used to produce furniture, lamps, etc. The strength and bending test of the copper tube must be ensured.

(5) Casing: It is also an ordinary carbon steel electric welded copper pipe. It is used in concrete and various structural power distribution projects. The commonly used nominal diameter is from 13-76mm. The wire sleeve has a thin wall and is mostly used after being coated or galvanized, requiring a cold bending test.

(6) Idler tube: Used for belt conveyor roller welding copper tube, generally made of Q215, Q235A, B steel and 20 steel, with a diameter of 63.5-219.0mm. There are certain requirements for the curvature of the pipe, the end face to be perpendicular to the center line, and the ovality. Generally, water pressure and flattening tests are performed.

(7) Transformer tube: used to manufacture transformer heat pipes and other heat exchangers. It is made of ordinary carbon steel and requires flattening, flaring, bending and hydraulic testing. Copper pipes are delivered in fixed lengths or multiple lengths, and there are certain requirements for the bending of the copper pipes.

(8) Special-shaped pipes: square pipes, rectangular pipes, hat-shaped pipes, and copper pipes for hollow rubber steel doors and windows welded from ordinary carbon structural steel and 16Mn and other steel strips. They are mainly used as agricultural machinery components, steel windows and doors, etc.

(9) Electrically welded thin-walled tubes: mainly used to make furniture, toys, lamps, etc. In recent years, thin-walled tubes made of stainless steel strips have been widely used in high-end furniture, decorations, fences, etc.

(10) Spiral copper pipe: It is made by rolling low-carbon carbon structural steel or low-alloy structural steel strips into pipe blanks at a certain spiral angle (called forming angle), and then welding the pipe seams. It can Large diameter copper pipes are produced from narrower strips of steel. Spiral copper pipes are mainly used for oil and natural gas transmission pipelines, and their specifications are expressed by outer diameter * wall thickness. Spiral copper pipes are either single-sided or double-sided welded. The copper pipe should ensure that the hydraulic pressure test, tensile strength and cold bending performance of the weld meet the regulations.

1. Q: What kind of work does your company do?

A: Our company is a professional steel products manufacturer. We mainly produce stainless steel, carbon steel, aluminum, copper plate / pipe / coil / bars and so on.

2. Q: What are the advantages of your company?

A: Prime quality and reasonable price, wide excellent experiences with after-sale service, every process will be checked by responsible QC which ensures every products quality, professional packing teams which keep every packing safely, trial order can be done in one week, samples can be provided as your requirements.

3. Q: What is your term of payment?

A: Payment<=1000USD,100% in advance, payment>=1000USD, 30%T/T in advance, balance based on BL copy or LC at sight. If you have another question, please contact us as below.

4. Q: What about your price?

A: Our price is very competitive, because we are a factory. if you are interested in our products, please feel free to contact us.

5. Q: How long is your delivery time?

A: Different products have different delivery time. The product will press deliver as soon as possible on the basis of quality assurance. Usual delivery time is 15 days after receiving the deposit.

Hot Searches