- Product Details

- {{item.text}}

Quick Details

-

Print Dimension:

-

1900mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM- Xfy

-

Dimensions(L*W*H):

-

3070*1090*1610mm

-

Weight:

-

250 KG

-

Ink Type:

-

Sublimation Ink

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Ink type:

-

Sublimation Ink

-

Item Name:

-

InkFa-5193E

-

Application:

-

Indoor Outdoor Advertisement

-

Color:

-

CMYK

-

Print head:

-

3*4720

-

Print speed:

-

120m2/hour

-

Printing size:

-

1900mm

-

Media Type:

-

Sublimation paper

-

After Warranty Service:

-

Video technical support

Quick Details

-

Plate Type:

-

Screen Printer

-

Color & Page:

-

Multicolor

-

Voltage:

-

220V 50~60HZ

-

Print Dimension:

-

1900mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM- Xfy

-

Dimensions(L*W*H):

-

3070*1090*1610mm

-

Weight:

-

250 KG

-

Ink Type:

-

Sublimation Ink

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Ink type:

-

Sublimation Ink

-

Item Name:

-

InkFa-5193E

-

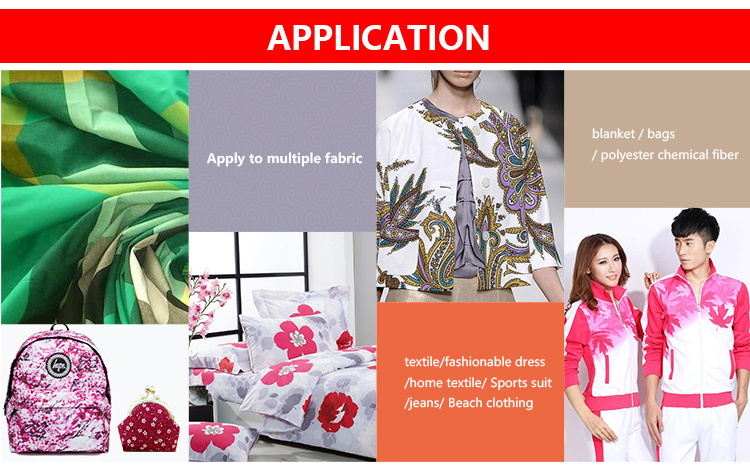

Application:

-

Indoor Outdoor Advertisement

-

Color:

-

CMYK

-

Print head:

-

3*4720

-

Print speed:

-

120m2/hour

-

Printing size:

-

1900mm

-

Media Type:

-

Sublimation paper

-

After Warranty Service:

-

Video technical support

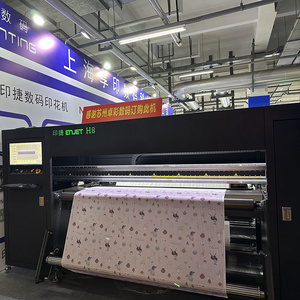

| Printer Model | XF-5193E | |

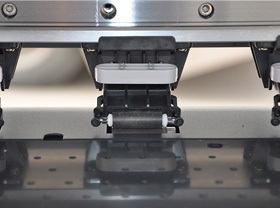

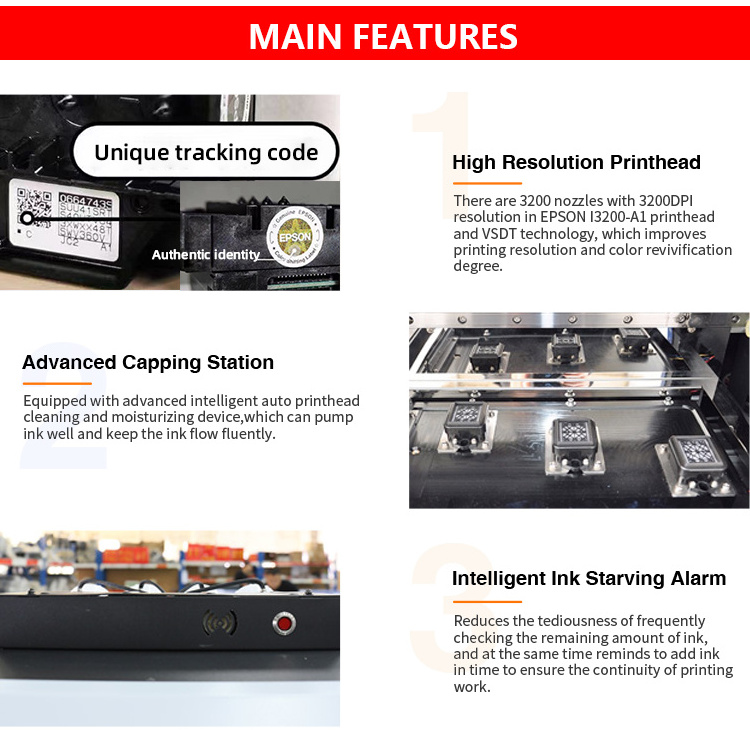

| Printhead | Type | EPSON I3200-A1 |

| Nozzle Qty | 3pcs printheads | |

| Height to Platform | 2-5mm | |

| Printing Speed | 2pass 120sqm/h | |

| 3pass 85sqm/h | ||

| 4pass 65sqm/h | ||

| 6pass 45sqm/h | ||

| Ink | Color | C M Y K |

| Type | Dye Sublimation | |

| supply method | Siphoning | |

| Max Printing Width | 1900mm | |

| Printing Media | Transfer Paper | |

| Media Transfer Method | Dual-drive tension take-up system,Auto air shaft feeding system | |

| Drying Method | External,Intelligent and air-heat Integrated drying system | |

| Moisture Mode | Fully sealed auto moisturing and cleaning | |

| RIP Software | Maintop6.0,Photoprint,Onyx,Wasatch and NeoStampa and etc. | |

| Image Format | JPG,TIF,PDF,BMP and etc. | |

| Computer | System | WIN7 64bit/WIN10 64bit |

| Hardware |

Hard disk:500G (system disk more than 100G)

GPU:ATI Discrete CD-ROM:DVD ROM Memory:4G or more CPU:Intel i5/i7 processor |

|

| Transmit Port | Gigabit LAN | |

| Work Environment | Temperature 20-35 centi degree; Humidity 35-65% | |

| Power | Input Voltage | 210-230VAC 50/60HZ 16A |

| Printing system | 1000W | |

| Drying system | Max power 3500W | |

| Dimension | Printer Dimension | 3066*880*1553mm |

| Packing Dimension | 3250*950*1060mm | |

| Weight | Net Weight | 351KG |

| Gross Weight | 482KG | |

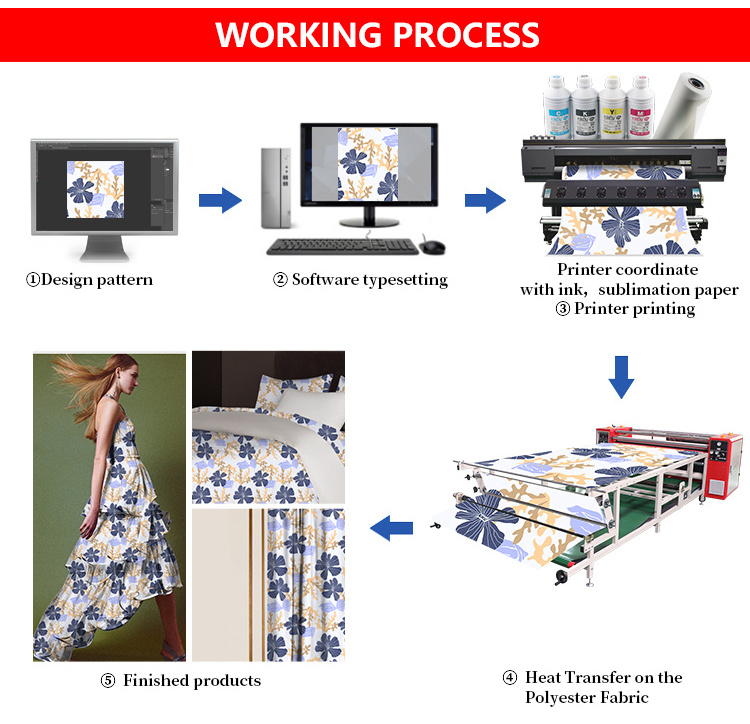

How to choose sublimation printer? These factors can not be ignored

With the continuous expansion of individual needs, digital printing become more and more popular. Face to the market, how to choose dazzled printer? XinFlying digital printer remind you some factors to consider carefully as follows.

Digital printing technology to abandon the shortcomings of traditional printing technology, no plate making, high precision, environmental protection, flexible batch. With the above advantages, digital printing blowing a whirlwind of personalized customization in the printing industry. Want to make a good personalized products, a high-quality printing equipment can not be less.

1.Printing Technology

The most common two printing technologies of digital printer are direct inkjet printing and thermal transfer printing, different printing technology corresponds to different types of digital printer. Two printing technologies both pros and cons dependent. The thermal transfer printing have high precision and small investment, but applicable fabrics are limited. The direct inkjet printing is opposite, suitable for a wide range of fabrics, but big investment and high cost.

2.Printing Precision

Different fabrics on the printing precision requirements are different, such as silk, chiffon and other more exquisite fabrics on the high precision, while canvas, sweaters and other more rough fabrics on the lower precision. Printing machine precision is inversely proportional to printing efficiency, the higher the precision, the lower the efficiency.

3.Printing Ink

Ink directly affect the screen output, different ink printing effect is different. We can according to our own requirement and fabric on ink to choose four color ink, six color ink, eight color ink and so on. Generally, the more color ink and the better color saturation and color of the printing, it also directly decide the color type of printer.

4.Printing Printhead

The printhead as the most important part and the main material of digital printer, it plays a decisive role in the choice of digital printer. The type of printhead decide to printing precision, the amount of inkjet, printing speed, the cost of production and so on. The choice of printhead to consider the type of printing fabric, cost estimates, the requirement of production efficiency and other factors, the printhead as the main material should consider all aspects the replacement of cost and durability.

The core standard of choosing digital printer is: Not to choose expensive, only choose the right! Keep in mind the above factors, let you choose the most suitable digital printer easily.

At present, XinFlying products have been sold to all over the world, including U.S.A., Canada, Germany, Poland, Brazil, Peru, Australia, Russia, Singapore, South Africa, India, Thailand, Philippines, Pakistan and other more than 30 countries. And we have cooperated with several professional company both at home and abroad for long-term, stable relations of cooperation, becoming excellent supplier of the world famous printing companies.

After-Sale Service:

1. If you use our ink, we will always provide you with free repair service

2. technologists can speak fluent english and provide instant online support service

3. free technical training will be provided in the f

actory

4. we will send you spare parts and inks in lower price

5. we can issue you excludsive dealership after we confirm our cooperation and we will 100% loyal to our dealers

6. we can arrange technicians to visit you for supporting the booth and training freely if you display our machines in exhibition.

Machine Maintenance Instructions:

1. As for the ink cap, scraper and lifting plate clean, must be kept clean all the time.

2. Need to put some lubricating oil on the trolley track for every half a month or for every month .

3. Grating need be wiped with dry clean fabric for every month.

4. Need to put some water into the ink stack cap while the the machine is printing. It greatly keeps the ink cap wet to prevent agglomeration and the print head blocked.

5. It is best to turn on the machine in two or three days if you do not use the machine for long time. And print the test strip or print some tasks to prevent the print head blocked.

6. The machine need to be kept cleaned all the time . If can kept like a new machine, which will better.

FAQ

Q: What ’ s the machine installation?

A: We provide the machine usage & installation videos and instruction manual, afford the 24 hour online service support for oversea customers. If need, we could provide the on-site installation and training service.

Q: How about the machine ’ s package and transportation ?

A: Each machine before leave the factory will be protected by film, be f asten ed on the bottom of the wooden case with iron nails , after the machine be packed, we will choose the transportation way and export service according customer ’ s requirement.

Q: How about the machine ’ s maintenance ?

A : With warranty of whole printer ( not included the printer head) , simultaneously we will provide the lifetime warranty if use together with our ink. Also our after-sales engineers will provide 24 hour online technical consulting service.