- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

YR1414

-

Product Name:

-

plastic mold concrete hollow interlock block

-

Mould material:

-

PP, ABS, Rubber

-

Block Type:

-

interlocking hollow block

-

Color:

-

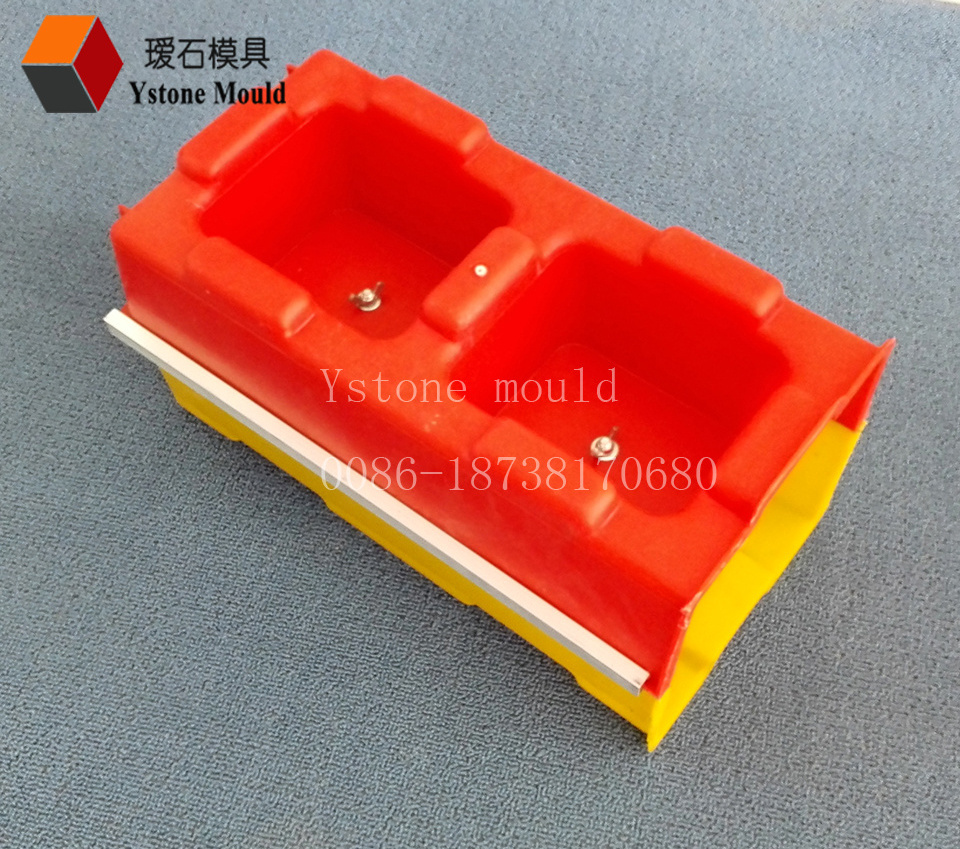

Red and Yellow

-

Lifespan:

-

1000 casting

-

Size:

-

400x200x200mm

-

Accessory:

-

clips, bolts and nuts

-

Application:

-

Making concrete blocks for building

-

quality:

-

strong and durable

-

Packing:

-

Cartons

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Ystone

-

Model Number:

-

YR1414

-

Product Name:

-

plastic mold concrete hollow interlock block

-

Mould material:

-

PP, ABS, Rubber

-

Block Type:

-

interlocking hollow block

-

Color:

-

Red and Yellow

-

Lifespan:

-

1000 casting

-

Size:

-

400x200x200mm

-

Accessory:

-

clips, bolts and nuts

-

Application:

-

Making concrete blocks for building

-

quality:

-

strong and durable

-

Packing:

-

Cartons

plastic mold concrete hollow interlock block

|

plastic mold concrete hollow interlock block: 1, Including: 1 red, 1 yellow, two clips, two bolts and nuts. 2, Size: Big mold of 400X200X200mm small mold of 200X200X200mm 3, Weight: 1.4KG with big mold, 0.7KG with small mold. 4, The hollow block is interlocking extremely precisely with the next blocks, either in line or at right angles.

|

|

|

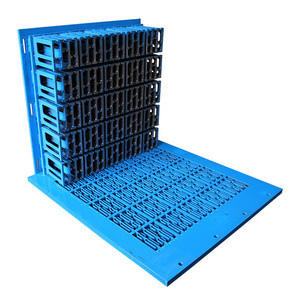

Why Use interlocking block moulds?.

Cheaper:

Using interlocking block mould is cheaper because they use MUCH LESS CEMENT than standard blocks and DON'T REQUIRE MORTAR BETWEEN COURSES or between blocks. No electricity, petrol or diesel required in the manufacture, only local sand and cement. The blocks are usually about 65% cheaper to produce than purchasing standard blocks.

Quicker:

Because they interlock and are therefore just slotted into place. No time is wasted laying down mortar for each course of blocks and endlessly levelling blocks. Construction can be achieved in record time: eg. a 3m x 4m room can be built to roof height in 1 day (with 4 men)

Easier:

Laying each block in place takes seconds because they interlock. The only tools required for making blocks are a mould, a shovel (for mixing) and a builder's trowel (for finishing).

Stronger:

Because they are 'wet moulded', not 'dry moulded, like standard blocks.

Much more accurate:

Each block is exactly 400mm x 200mm x 176mm, and they interlock extremely precisely with the next block, either in line or at right angles.

Cooler:

Each full block has two large air-filled cavities which are natural thermal insulators, and also allow the warm air in the cavities to rise and exit the house.

Practical:

Electical cable and plumbing is not chased into walls, but is led through the cavities in the blocks. These cavities may also be filled with insulating foam or polystyrene granules for further insulation. No lintels required above doors/windows less than 1.5m wide.

No special skill required:

People with little or no education or skill can manufacture and lay the blocks. Only limited training is required.

On-site manufacturing:

Blocks are usually manufactured on-site, thus eliminating transport costs.