- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

1.3 kN

-

Theoretical Shot Volume(cm³):

-

74 cm³

-

Injection Rate (g/s):

-

76.7 g/s

-

Injection Weight (g):

-

67 g

-

Screw Speed (rpm):

-

0 - 200 rpm

-

Screw diameter (mm):

-

30 mm

-

Distance between Tie Bars:

-

295mm

-

Weight (KG):

-

800 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

180 mm

-

Model Number:

-

CY-200S2

-

Brand Name:

-

CANYANG

-

Power (kW):

-

5.5 kW

-

Product name:

-

Plastic Injection Moulding Machine

-

Keyword:

-

Vertical Plastic Injection Moulding Machine

-

Function:

-

Multifunctional Plastic Products Making

-

Application:

-

Inserting Plastic Products

-

Plastic Type:

-

PE/PP/PVC

-

Used for:

-

Plasic Products

-

BRAND:

-

CANYANG

-

Machine Color:

-

Green + red

-

Voltage:

-

Customed Avaiable

-

Motor:

-

3.7KW/5HP

Quick Details

-

Mold Height(mm):

-

30 - 210 mm

-

Ejector Number:

-

16

-

Ejector Stroke(mm):

-

35 mm

-

Ejector Force(kN):

-

1.3 kN

-

Theoretical Shot Volume(cm³):

-

74 cm³

-

Injection Rate (g/s):

-

76.7 g/s

-

Injection Weight (g):

-

67 g

-

Screw Speed (rpm):

-

0 - 200 rpm

-

Screw diameter (mm):

-

30 mm

-

Distance between Tie Bars:

-

295mm

-

Weight (KG):

-

800 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

180 mm

-

Model Number:

-

CY-200S2

-

Brand Name:

-

CANYANG

-

Power (kW):

-

5.5 kW

-

Product name:

-

Plastic Injection Moulding Machine

-

Keyword:

-

Vertical Plastic Injection Moulding Machine

-

Function:

-

Multifunctional Plastic Products Making

-

Application:

-

Inserting Plastic Products

-

Plastic Type:

-

PE/PP/PVC

-

Used for:

-

Plasic Products

-

BRAND:

-

CANYANG

-

Machine Color:

-

Green + red

-

Voltage:

-

Customed Avaiable

-

Motor:

-

3.7KW/5HP

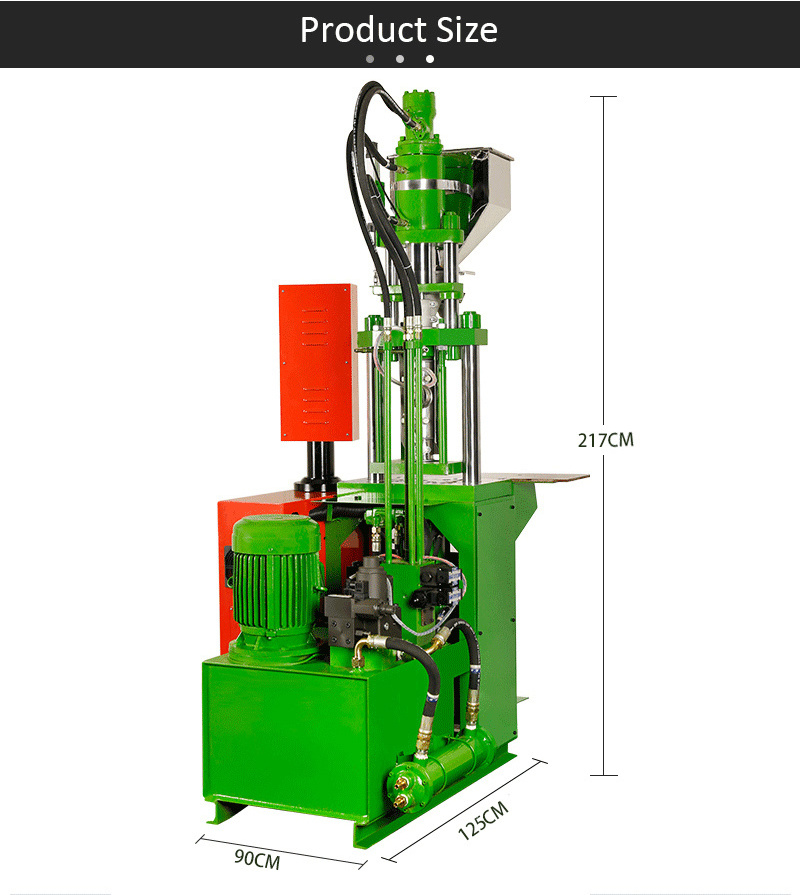

30T Desktop Silicon Eva Slipper Pen Mobile Covers Plug Making Injection Mold Moulding Machinery Vertical Plastic Molding Machine

CY-200S2 Machine Characteristics:

1. CY-200S2 is a two-column molding machine with compact body and light weight. It adopts vertical opening and closing mold and injection glue to perfectly solve the mosaic injection molding;

2. Equipped with a light-adjustable upper template to facilitate mold installation and replacement;

3. Top-mounted pre-plasticized motor, high-precision transmission and reduced machine height, saving a lot of space in the factory;

4. Vertical hydraulic mold closing structure, fast and low power consumption during mold closing;

5. High-quality nitrided alloy steel pipe set, high wear-resisting and anti-reverse structure, long service life of screw;

6. The temperature control system adopts computer PID control, which is intuitionistic and easy to operate, and the material temperature is accurate

7. The hydraulic system adopts multi-stage pressure independent control, linear control of speed and temperature, precise control of injection glue, opening and closing mode and other actions to make the production injection stable, and the appearance of the product is beautiful;

8. The closed mode and the injection adopt the closed-loop feedback position information of the grating ruler, and the position control is more precise

9. The electrical appliance is equipped with safety protection device to maintain the safety of the operator; and the fault alarm information display makes the maintenance easier and convenient;

10. The computer adopts large-screen LCD design, intuitive and easy-to-operate human-machine interface, and is free to switch between Chinese, English, Russian and Korean four languages; it can store 60 sets of mold parameter memory, and the production adjustment is easy and efficient.

1. CY-200S2 is a two-column molding machine with compact body and light weight. It adopts vertical opening and closing mold and injection glue to perfectly solve the mosaic injection molding;

2. Equipped with a light-adjustable upper template to facilitate mold installation and replacement;

3. Top-mounted pre-plasticized motor, high-precision transmission and reduced machine height, saving a lot of space in the factory;

4. Vertical hydraulic mold closing structure, fast and low power consumption during mold closing;

5. High-quality nitrided alloy steel pipe set, high wear-resisting and anti-reverse structure, long service life of screw;

6. The temperature control system adopts computer PID control, which is intuitionistic and easy to operate, and the material temperature is accurate

7. The hydraulic system adopts multi-stage pressure independent control, linear control of speed and temperature, precise control of injection glue, opening and closing mode and other actions to make the production injection stable, and the appearance of the product is beautiful;

8. The closed mode and the injection adopt the closed-loop feedback position information of the grating ruler, and the position control is more precise

9. The electrical appliance is equipped with safety protection device to maintain the safety of the operator; and the fault alarm information display makes the maintenance easier and convenient;

10. The computer adopts large-screen LCD design, intuitive and easy-to-operate human-machine interface, and is free to switch between Chinese, English, Russian and Korean four languages; it can store 60 sets of mold parameter memory, and the production adjustment is easy and efficient.

Product Paramenters

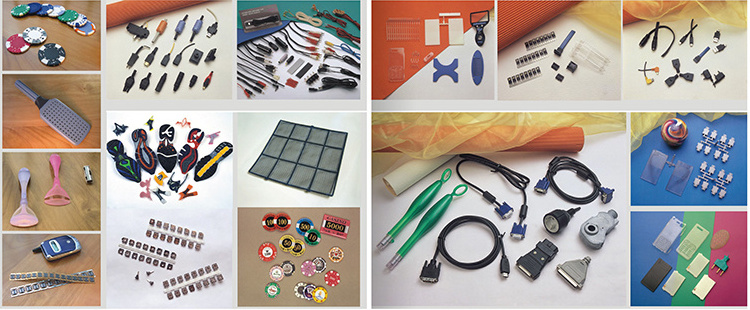

Application fields:

Widely used in the production of a variety of junction boxes, household appliances. consumer electronic products,power tools,automotive dashboards,medical devices, open containers, connectors, cables,auto parts,plugs and so on.

Widely used in the production of a variety of junction boxes, household appliances. consumer electronic products,power tools,automotive dashboards,medical devices, open containers, connectors, cables,auto parts,plugs and so on.

|

Machine suitable glue and temperature list

|

|

|

|

|

|

|

|

|||||||

|

CY-200S2 Plasti type

|

|

|

|

|

|

|

|

|||||||

|

Plasti type

|

TEMPERATURE SET

|

|

|

Hopper Temp

|

Screw RPM

|

Mold Temp

|

Contract

|

|||||||

|

|

Nozzle

|

First

|

Second

|

|

|

|

|

|||||||

|

PVC

|

170-220

|

160-195

|

150-190

|

60-80

|

30

|

15-60

|

0. 1-0. 5

|

|||||||

|

TPE(PE)

|

170-210

|

160-190

|

150-185

|

60-80

|

30

|

20-60

|

0. 1-0. 4

|

|||||||

Details Images

Product packaging

Our Advantages

Certifications

Hot Searches