- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

URC82

-

Voltage:

-

380V/50HZ, 220V

-

Dimension(L*W*H):

-

380x235x125mm

-

Year:

-

2021

-

Power (kW):

-

0.8 kW

-

Weight (KG):

-

15 KG

-

Name:

-

ultrasonic rubber cutter

-

Application:

-

rubber slicer machine

-

Function:

-

ultrasonic tire cutter machine

-

Type:

-

Handheld Ultrasonic Cutting

-

Frequency:

-

40khz

-

Power:

-

500watt

-

Tool material:

-

Titanium alloy

-

Available materials:

-

Rubber

-

Whether it is customized:

-

Yes

Quick Details

-

Cutting-off Force(T):

-

2 T

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Cheersonic

-

Model Number:

-

URC82

-

Voltage:

-

380V/50HZ, 220V

-

Dimension(L*W*H):

-

380x235x125mm

-

Year:

-

2021

-

Power (kW):

-

0.8 kW

-

Weight (KG):

-

15 KG

-

Name:

-

ultrasonic rubber cutter

-

Application:

-

rubber slicer machine

-

Function:

-

ultrasonic tire cutter machine

-

Type:

-

Handheld Ultrasonic Cutting

-

Frequency:

-

40khz

-

Power:

-

500watt

-

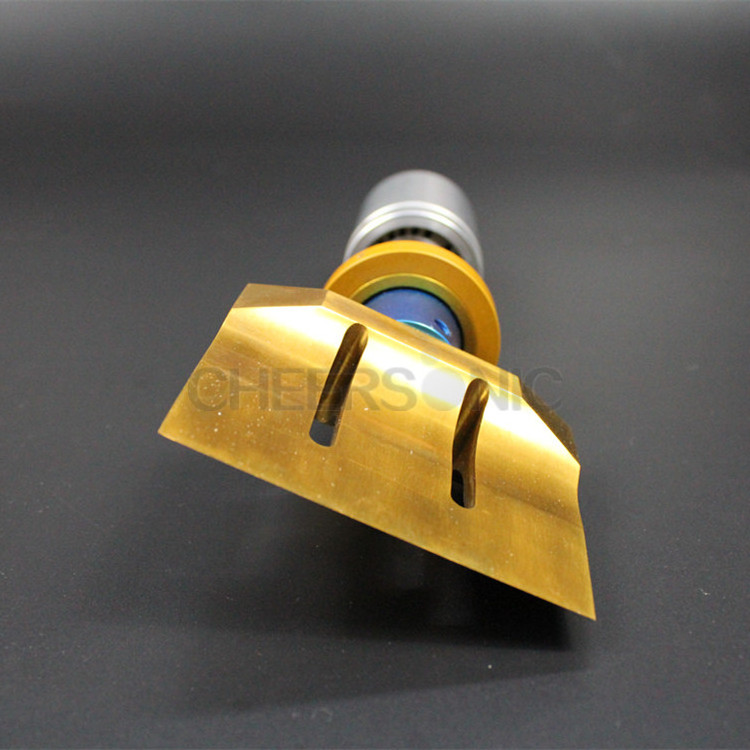

Tool material:

-

Titanium alloy

-

Available materials:

-

Rubber

-

Whether it is customized:

-

Yes

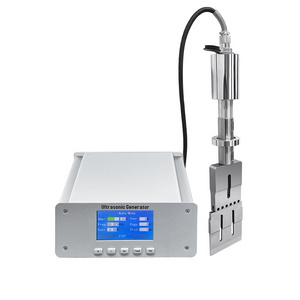

Overview of Ultrasonic Rubber Cutting Machine

Ultrasonic rubber cutting principle is through the ultrasonic generator 50 / 60Hz current into 20,30 or 40kHz power. The converted high frequency electrical energy is again converted into mechanical vibrations of the same frequency by means of transducers, which are then transmitted to the cutter through a set of amplitude modulator means which can vary the amplitude. The cutter transmits the received vibration energy to the cutting surface of the workpiece to be cut, in which the vibration energy is cut by activating the molecular energy of the rubber and opening the molecular chain.

Advantages of Ultrasonic Rubber Cutter

• High cutting accuracy, no deformation of the compound

• High speed, high efficiency, no pollution

• Cutting surface finish is good, good bonding performance

• Easy to use in automated production

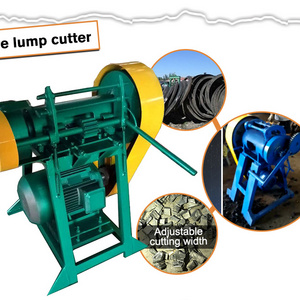

Ultrasonic Rubber Cutter Machine Applications

Used in tire, cable foreskin materials, hoses, gaskets and chemical-resistant equipment lining and other rubber products, cutting.

Choice of Cutting Methhod:

20kHz cutting knife in the upper tread cutting (which can be cross-cutting and longitudinal mode)

• A suitable amplitude and feed rate increase the cutting quality

• The key factors affecting the cutter are the knife’s angle, size, shape and thickness

• High power, more suitable for high-class cars, car tread cutting

• Common cutter types: 100mm, 255mm, 305mm, 350mm and other cutting knife

Cut the sidewall of the tire rubber using a 40 kHz cutter (typically in a cross-cutting mode)

• The cutting speed depends on the angle and thickness of the cut tire rubber

• The key factors affecting the cutter are the knife’s angle, size, shape and thickness

• For semi-steel tires, radial tires and other inner liner and sidewall cutting

• Common types of cutter: 82mm and other cutting knife

Parameter

| Model | Frequency | Power | Knife Width | Knife High |

| URC82 | 40khz | 500watt | 82mm | 70mm |

| URC100 | 20khz | 800watt | 100mm | 128mm |

| URC255 | 20khz | 1000watt | 255mm | 128mm |

| URC305 | 20khz | 1500watt | 305mm | 128mm |

Video

https://youtu.be/HREPYacrcBM

Packaging & Shipping ·

Choose Cheersonic ·

Founded in 1998, Cheersonic is the manufacturer and marketer of industrial ultrasonic products. As an industrial leader of ultrasonic technology, Cheersonic specializes in the design, development, manufacture, and marketing of ultrasonic products in the line of food process, plastics joining, medical coating and ultrasonic processing. Cheersonics principal manufacturing and distribution facility is located in Fuyang, Zhejiang province.

We develop and produce ultrasonic equipments which we sell as complete units or individual assembles such as generators and converters. Our customers and special purpose machine builders benefit from high-quality components and machines with simple, user-friendly operation. We are committed to providing solutions that can meets the needs of our customers, providing the latest in technology, both in products and processes.

For us, quality is not just an empty word but a basic attitude which is the foundation for our thinking and actions. Each product has checked by our QC department before sending to our customers.

-

Free test

-

Economic, Environmental & compatible design of all products

-

Easy maintenance & inexpensive spare parts

-

24 hours technical supports and after sales services

-

Diversity of customized services, Strong OEM capability available

-

One step sourcing on all ultrasonic products

-

The most professional team in line of ultrasonic

Certificate ·

How to work with cheersonic ·

-

Visit the website for more details and send us the enquire, we will reply it within 24 hours

-

Welcome to visit our official website for more details and leave message on“contact us", we will reply it within 24 hours

-

Let our sale engineers know your condition and requirement and then we will estimate your process and let you know the solutions

-

We will help you test and estimate if you send us your materials for test

-

The ultrasonic solutions will be made according to your condition