1. Decoiler: electric discharge, hydraulic tensioning

2. Load-bearing capacity of uncoiler: ≤5T

3. Inner diameter of uncoiling machine: φ508mm

4. Rolling range: φ450-φ530mm

5. Decoiler power: 5.5KW

6. Hydraulic system power of decoiler: 3KW

7. Oil pump of hydraulic system of decoiler: vane pump

8. Solenoid valve of decoiler hydraulic system

9. Uncoiler electrical control system: main electrical components such as frequency converters adopt well-known brands

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

1.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Yowin

-

Voltage:

-

380V/ 3phase/ 50 Hz

-

Weight:

-

10000 kg

-

Marketing Type:

-

New Product

-

Product name:

-

Scaffolding roll forming machine

-

Guided feed rack form:

-

lateral roller type

-

Forming machine structure:

-

cast iron arch type gearbox transmission

-

Rollers:

-

18 channels

-

Shaft material:

-

40Cr quenched and tempered (HB220-260)

-

Shaft diameter:

-

75mm

-

Unfolding width of rolled material:

-

subject to the width of the actual test machine plate

-

Roller material:

-

Gcr15

-

Roll heat treatment method:

-

quenching treatment (HRC58-62)

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

0-25m\min

-

Rolling thinckness:

-

1.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Yowin

-

Voltage:

-

380V/ 3phase/ 50 Hz

-

Weight:

-

10000 kg

-

Marketing Type:

-

New Product

-

Product name:

-

Scaffolding roll forming machine

-

Guided feed rack form:

-

lateral roller type

-

Forming machine structure:

-

cast iron arch type gearbox transmission

-

Rollers:

-

18 channels

-

Shaft material:

-

40Cr quenched and tempered (HB220-260)

-

Shaft diameter:

-

75mm

-

Unfolding width of rolled material:

-

subject to the width of the actual test machine plate

-

Roller material:

-

Gcr15

-

Roll heat treatment method:

-

quenching treatment (HRC58-62)

Product Description

Business remarks:

1. Warranty: 12 months since delivery.

2. Payment term:30% deposit, 70% balance before shipping.

3. Offer validity: 30Producing time:50 days.

Installation locally policy: purchase takes in charge of the cost for each engineer.

2. Payment term:30% deposit, 70% balance before shipping.

3. Offer validity: 30Producing time:50 days.

Installation locally policy: purchase takes in charge of the cost for each engineer.

Included: round-trip air tickets , accommodation and $150/day

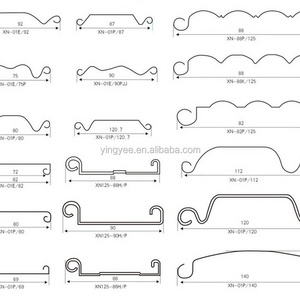

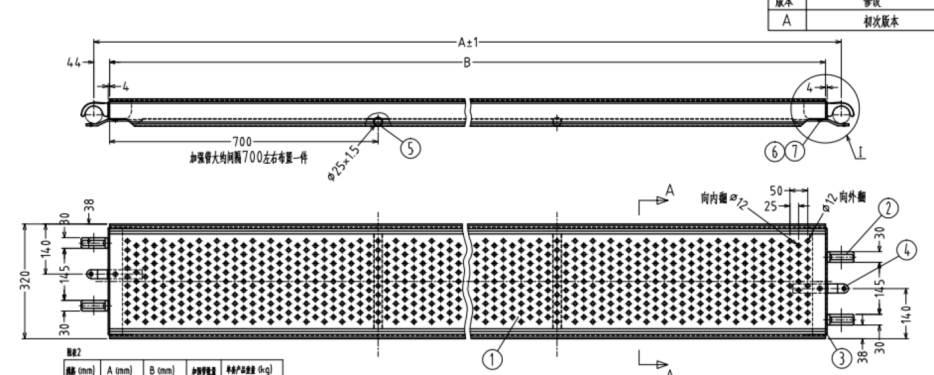

Drawings

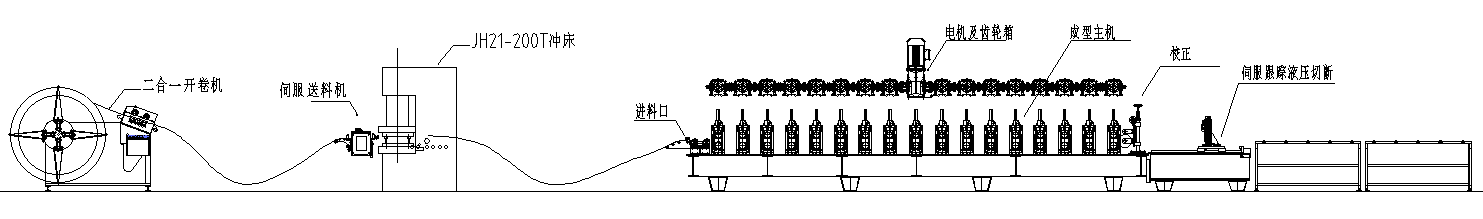

Processes and components

5 ton de-coiler with leveling x1 set

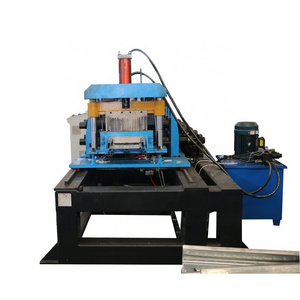

Servo feeding machine x1 set

125T Punching machine with moulds x1 set

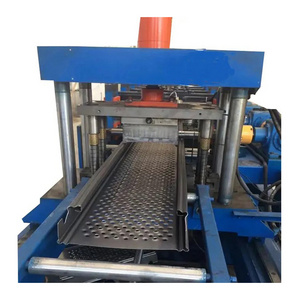

Main roll forming machine x1 sets

Servo track cutting x1 sets

Hydraulic station x1 set

PLC Control system x1 set

Run-out table (3M*2) x1 se

Servo feeding machine x1 set

125T Punching machine with moulds x1 set

Main roll forming machine x1 sets

Servo track cutting x1 sets

Hydraulic station x1 set

PLC Control system x1 set

Run-out table (3M*2) x1 se

Working Process

Technical parameters

1. 5T decoiler with leveling(2 in1)

2.Servo feeding system with punching machine

1. Feeder model: NC-400

2. Servo motor power: 3KW

3. Punch: JH21-125T

2. Servo motor power: 3KW

3. Punch: JH21-125T

4.Punching die: 1 set (stepping 500x punching times 50=25 meters per minute)

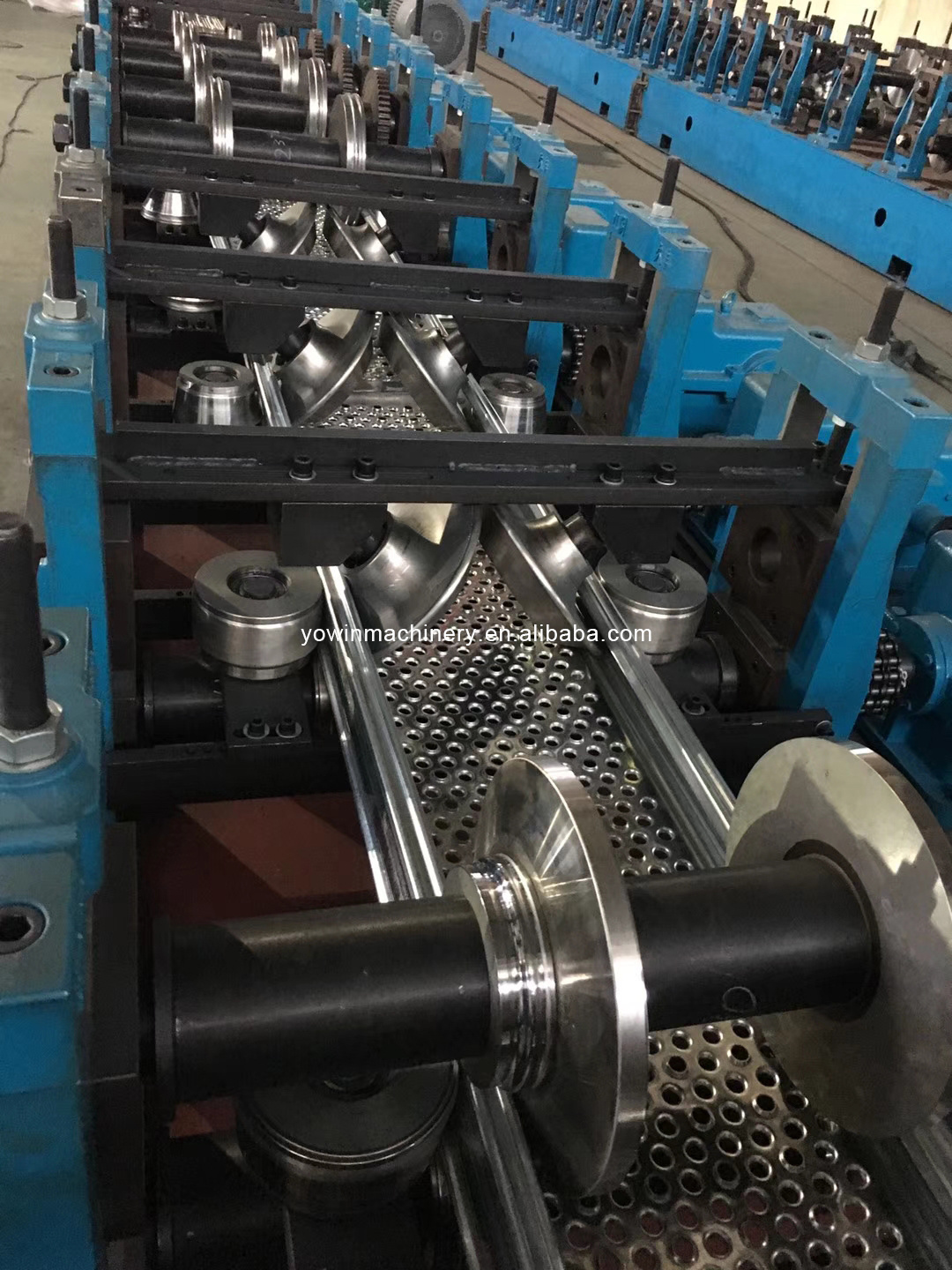

3.Roll forming machine

1. Forming machine frame: high-quality section steel aging treatment after welding

2. Guided feed rack form: lateral roller type

3. Forming machine structure: cast iron arch type gearbox transmission

4. Power of main motor of forming machine: 18.5KW (hard tooth surface reducer)

5. Speed of forming machine: 0-25m\min

6. Rollers: 18 channels

7. Shaft material: 40Cr quenched and tempered (HB220-260)

8. Bearing brand: Harbin

9. Shaft diameter: Φ75mm

10. Rolling thickness: 1.8mm

11. Unfolding width of rolled material: subject to the width of the actual test machine plate

12. Roller material: Gcr15

13. Roll heat treatment method: quenching treatment (HRC58-62)

2. Guided feed rack form: lateral roller type

3. Forming machine structure: cast iron arch type gearbox transmission

4. Power of main motor of forming machine: 18.5KW (hard tooth surface reducer)

5. Speed of forming machine: 0-25m\min

6. Rollers: 18 channels

7. Shaft material: 40Cr quenched and tempered (HB220-260)

8. Bearing brand: Harbin

9. Shaft diameter: Φ75mm

10. Rolling thickness: 1.8mm

11. Unfolding width of rolled material: subject to the width of the actual test machine plate

12. Roller material: Gcr15

13. Roll heat treatment method: quenching treatment (HRC58-62)

4. Servo track cutting system

1. Cutting method: hydraulic waste cutting after forming (servo tracking)

2. Servo motor power: 3KW

3. Ball screw and linear guide: domestic well-known brand

4. Shear blade material: Cr12mov

5. Heat treatment method of shear blade: quenching treatment (HRC58-62)

6. Hydraulic system power: 11KW (single circuit)

7. Solenoid valve of hydraulic system

8. Hydraulic system oil pump

9. Hydraulic system with air cooling

2. Servo motor power: 3KW

3. Ball screw and linear guide: domestic well-known brand

4. Shear blade material: Cr12mov

5. Heat treatment method of shear blade: quenching treatment (HRC58-62)

6. Hydraulic system power: 11KW (single circuit)

7. Solenoid valve of hydraulic system

8. Hydraulic system oil pump

9. Hydraulic system with air cooling

Specification

|

item

|

value

|

|

Applicable Industries

|

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction works

|

|

Type

|

Tile Forming Machine

|

|

Tile Type

|

Colored Steel

|

|

Production Capacity

|

0-25m\min

|

|

Place of Origin

|

China

|

|

Voltage

|

380V/ 3phase/ 50 Hz

|

|

Weight

|

10000kg

|

|

Warranty

|

2 years

|

|

Key Selling Points

|

High Productivity

|

|

Rolling thinckness

|

1.8mm

|

|

Feeding width

|

Other

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

2 years

|

|

Core Components

|

Pressure vessel, Motor, Other, Bearing, Gear, Pump, Gearbox, Engine, PLC

|

|

Product name

|

Scaffolding roll forming machine

|

|

Guided feed rack form

|

lateral roller type

|

|

Forming machine structure

|

cast iron arch type gearbox transmission

|

|

Rollers

|

18 channels

|

|

Shaft material

|

40Cr quenched and tempered (HB220-260)

|

|

Shaft diameter

|

75mm

|

|

Unfolding width of rolled material

|

subject to the width of the actual test machine plate

|

|

Roller material

|

Gcr15

|

|

Roll heat treatment method

|

quenching treatment (HRC58-62)

|

Hot Searches