We can design machine planning drawings according to your site.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

40*10*10m

-

Year:

-

2023

-

Power (kW):

-

300 kW

-

Weight (KG):

-

40000 KG

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUXI

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

40*10*10m

-

Year:

-

2023

-

Power (kW):

-

300 kW

-

Weight (KG):

-

40000 KG

-

Certification:

-

CE

Product Description

The waste tire recycling machine

is a piece of new innovative equipment. Rubber powder production line is used for processing used tires and rubbers to fine rubber powders.

End product size can reach 30-120 mesh free of steel wire and fiber.

|

Capacity

|

500-10000kg/h

|

|

Scope of application

|

The diameter of the tire:400-3000mm

|

|

Output size

|

5-100 mesh, can be Customized

|

|

Complete separation

|

The rubber Crumbs, Steel and Fiber can be separated automatically. Adopt PLC control system, it is only needs 4-6 persons to operate a Tire recycling(granule)production line with 3000 kg/h capacity. Low energy consumption. The installed powder of Tire recycling production(granule)line with capacity 3000 kg/h is about 800 kw.

|

|

Equipment required area

|

About 680 square meter, 7m height

|

|

Characteristic of blade

|

Long service life.High utilization, Multiple maintenances.

|

Final Product

How about your final product?

Our tire recycling machines can break down the waste tires into rubber granules, rubber powder, steel wire, and fiber.

Details Images

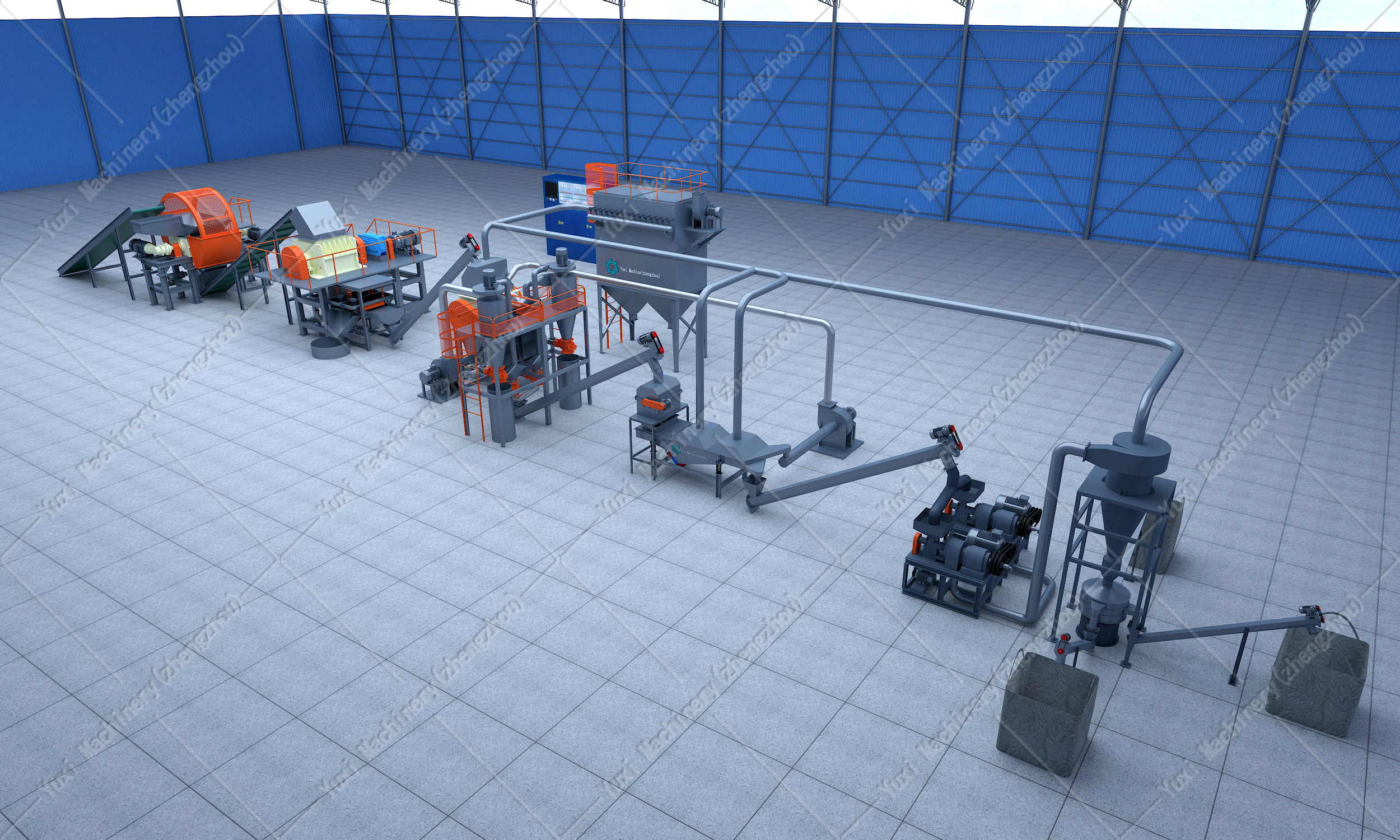

Schematic of tire recycling machine

Waste rubber tire powder recycling machine consists of tire broken machine host and auxiliary machine two parts. Auxiliary equipment: Hook Wire Drawing Machine, Tire Cutter Machine(Optional according to tire size), Conveyor, Magnetic Separator Machine, and other components.

Working Flow

Waste tire---Wire drawing machine---Rubber shredder--- Steel wire separating machine---magnetic separating ---Rubber powder.

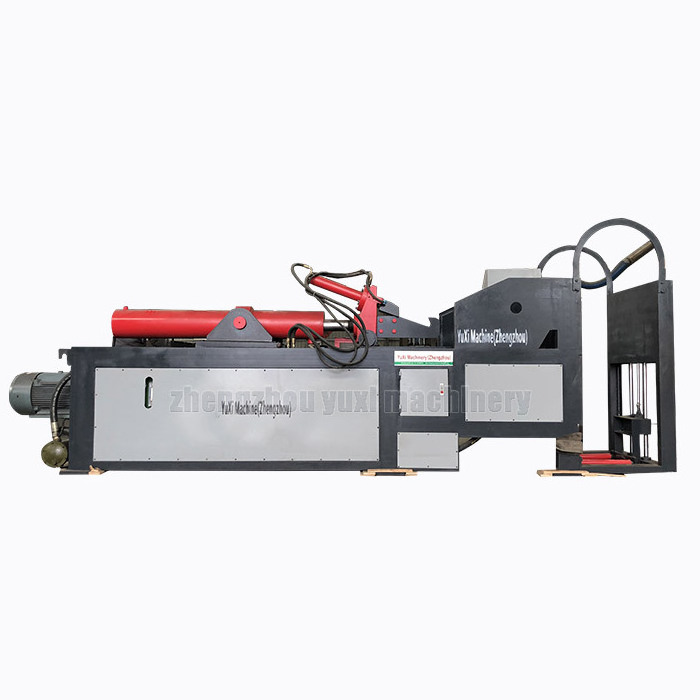

1. Steel wire drawing machine

--extract the thick steel wire.

2. Conveyor

-Transport the tire to the shredder.

3. Twin-shaft shredder

--Shears the tire into 5- 10 cm blocks;

4. Recirculation system

--To control the size of shreds going to the rapers;

5. Raspers

-Reduce the shreds into 15. 20 mm chips and liberates steel from the rubber;

6. Over belt magnet

--Separation of liberated steel from the rubber chips;

7. Vibratory feeder

--Transports the rubber chips;

8. Rubber granulator machine

--Size reduction of the chips to 1-4 mm granules and liberates the textile fraction to air flow separation.

9. Grinder machine

--Grinder rubber powder.

10.Central de-dusting unit

--Remove dust and fines from the system and filter the air before returning it to the atmosphere.

|

Double Shaft Shredder

|

|

The double shaft shredder pre-processes the

|

|

whole tire into approximately

50-80mm rubber

|

|

blocks.

|

|

Motor:

as per request

|

|

Steel Wire Separator

|

|

Input materials

≤50mm

tire rubber blocks finised

|

|

products

≤20mm. and

can

remove 96%

of the

|

|

tire steel wire.

|

|

Motor:

as per request

|

|

Reducer:

as per request

|

|

High Speed Crusher

|

|

Input materials ≤20mm

tire rubber blocks

|

|

finished products ≤2-6mm.

|

|

Motor:

as per request

|

|

Blades:

as per request

|

|

Product size:

one or more sizes are discharged at the same time.

|

|

Dust Collection

|

|

Dust collection system can collect dust and fiber

|

|

by the air pipe when the crushing machine

|

|

working.

|

|

Dust removal standard:

can be customized

|

|

according to the standards of different countries

|

|

Rubber Grinder

|

|

The rubber grinder is a device that

pulverizes 2-

|

|

6mm

pure rubber granules into a fine powder of

|

|

10-140 mesh

at room temperature.

|

|

Motor:

as per request

|

|

Product size:

one or more sizes are discharged at the same time.

|

More Pictures

Related Product

Semi-Automatic Type and Manual Type Equipment

Our Factory

Zhengzhou Yuxi Machinery Equipment Co. , Ltd.

is specialized in designing, researching, producing waste recycling equipment and provide waste treatment solutions. Yuxi factory has been working closely with well-known foreign enterprises to establish a good relationship between technical cooperation and market development. at the same time, 32 patents and 3 invention patents have been obtained.

High efficiency, energy saving, environmental protection

is the belief that our company has been firmly established. With high-quality products and core technology, our products are successfully exported to United States, Europe Australia, Southeast Asia, Middle East, South America and other more than 90 countries and areas, win the support and reliability of customers at home and abroad.

Working shop

Customer visit

Packaging & Shipping

1. Packaging: 1)Wrapped by the protective film;

2)Packed by standard import & export wooden cases or carton boxes.

2. Shipping: By logistics; by automobile; by train; by shipping; by air etc.

♥ Field installation, commissioning and training

♥

European customer installation site

Hot Searches