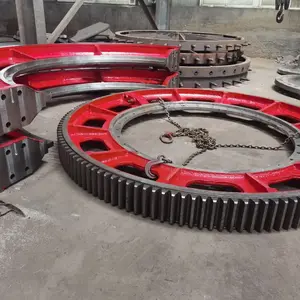

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Customize

-

Weight:

-

4500 kg

-

Product Name:

-

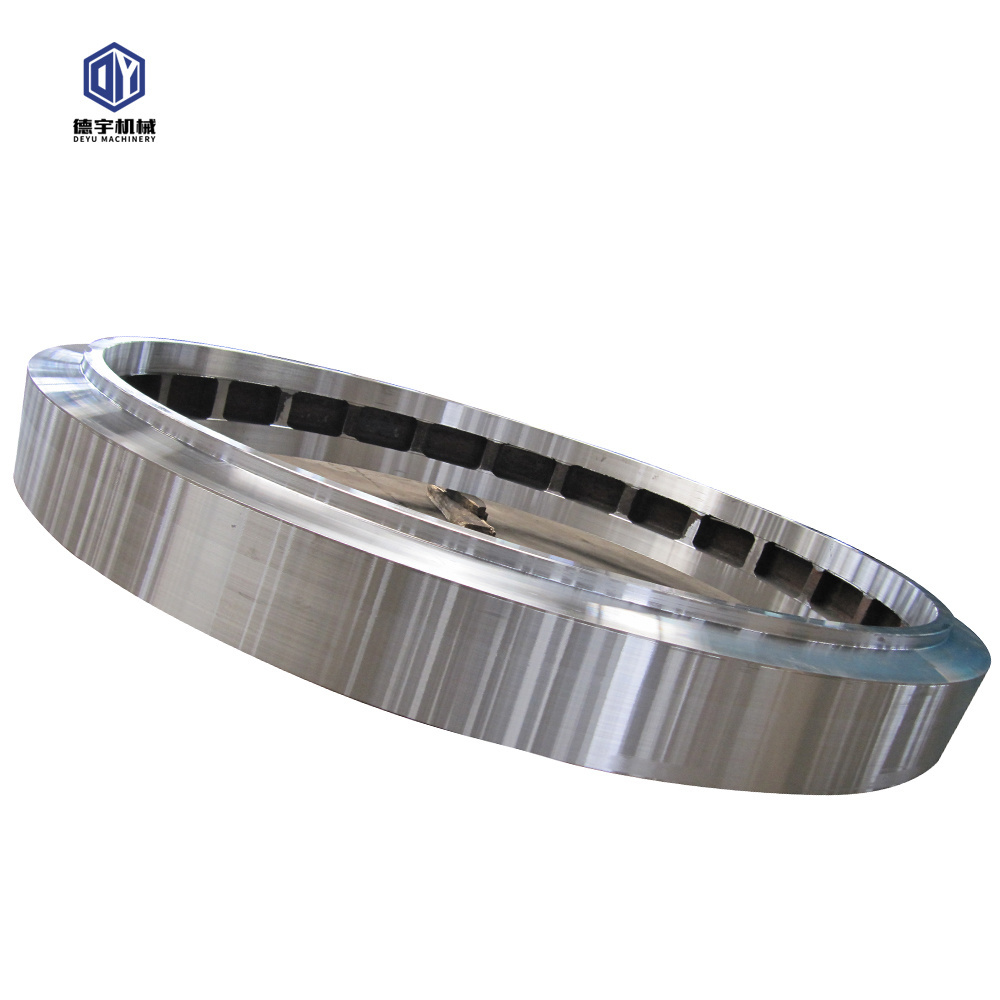

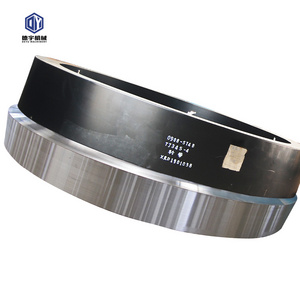

Riding Ring Tyre

-

Application:

-

Industry/Reudcer/gear box

-

Size:

-

Customer's Drawing

-

Processing:

-

Hobbing/Milling

-

Material:

-

4140/4340

-

Heat Teatment:

-

QT

-

Item:

-

Cement dryer Machine gear

-

Quality Control:

-

Ut test

-

Certificate:

-

ISO9001

-

Hardness:

-

HB230-260

Quick Details

-

Marketing Type:

-

Hot Product 2022

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

deyu

-

Power:

-

Customize

-

Weight:

-

4500 kg

-

Product Name:

-

Riding Ring Tyre

-

Application:

-

Industry/Reudcer/gear box

-

Size:

-

Customer's Drawing

-

Processing:

-

Hobbing/Milling

-

Material:

-

4140/4340

-

Heat Teatment:

-

QT

-

Item:

-

Cement dryer Machine gear

-

Quality Control:

-

Ut test

-

Certificate:

-

ISO9001

-

Hardness:

-

HB230-260

|

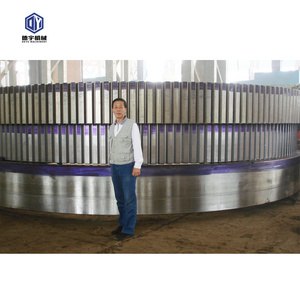

Product Name

|

kIln Tyre

|

|

Material

|

ZG45、ZG42CrMo (AIS4140),SC45 or other customized Material

|

|

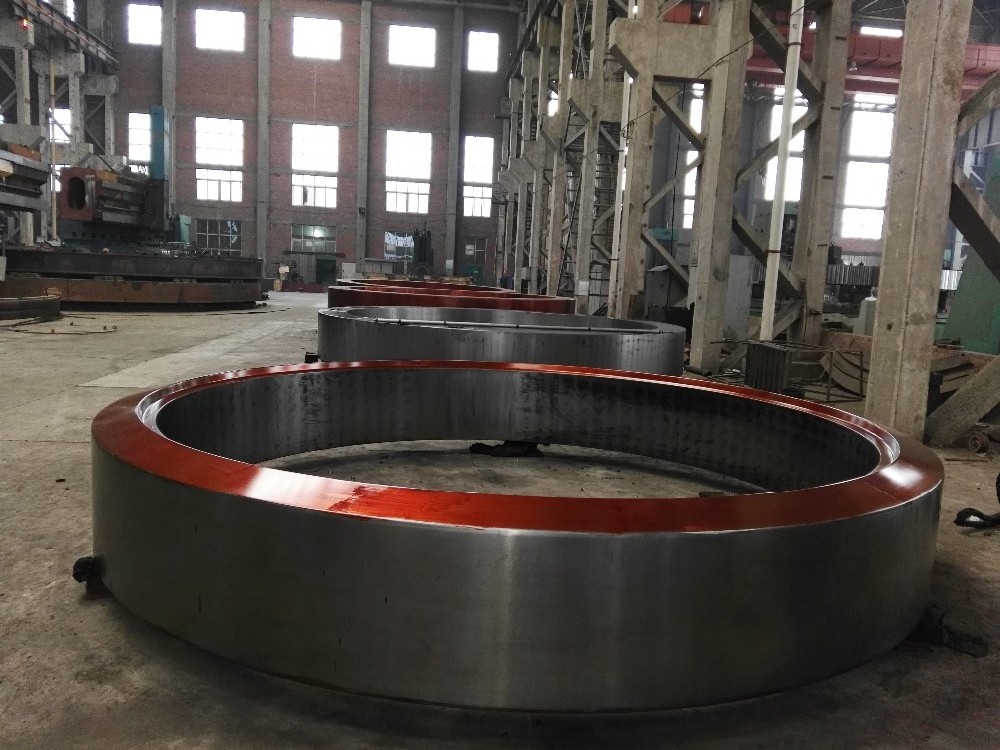

Weight

|

5-10tons

|

|

Application

|

Cement Rotary Kiln , Lime Rotary Kiln ,

Cement dryer etc.

|

Advantages:

Casting

Forging

years experience. We have three plant: a cold processing plant mainly engaged in shaft processing; a large-scale heat treatment equipment factory

mainly engaged in heat treatment processing; and a gear factory mainly engaged in big modulus gear processing. All of them have

the ISO9001 certificates.

treatment equipment, like, Gas Box Car-bottom Furnace,Heating Equipment,105kw Carburizing Furnace etc.

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 30~45 days. or it is according to quantity and technical requirement

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample.But it is not for free.

Q: What is your terms of payment ?

A: 50% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Jolie( Manager)

Tel:86-379-64086611; 86-379-60190828

Phone/wechat/whatsapp:86 18336769647

Skpe:qiuli.dong