- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3500*3200*2800mm

-

Year:

-

2022

-

Power (kW):

-

55 kW

-

Weight (KG):

-

5500 KG

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUXI

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3500*3200*2800mm

-

Year:

-

2022

-

Power (kW):

-

55 kW

-

Weight (KG):

-

5500 KG

-

Certification:

-

CE ISO

Products Description

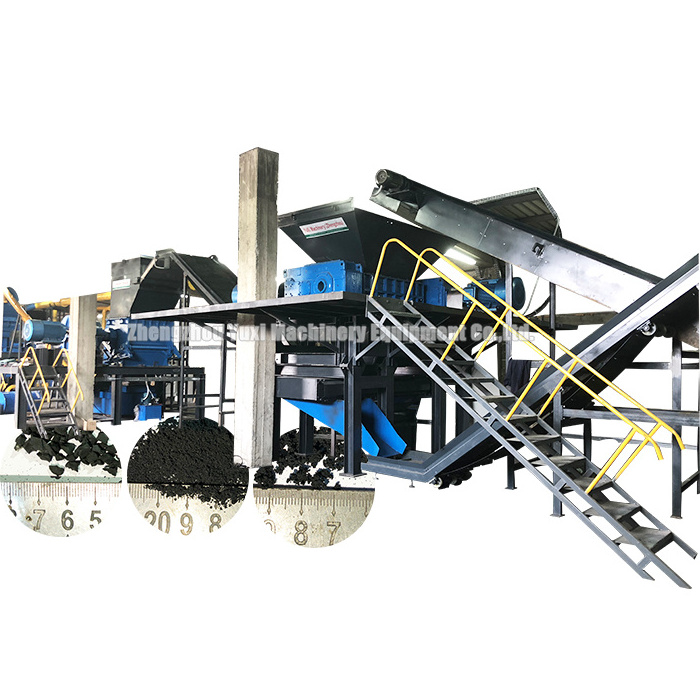

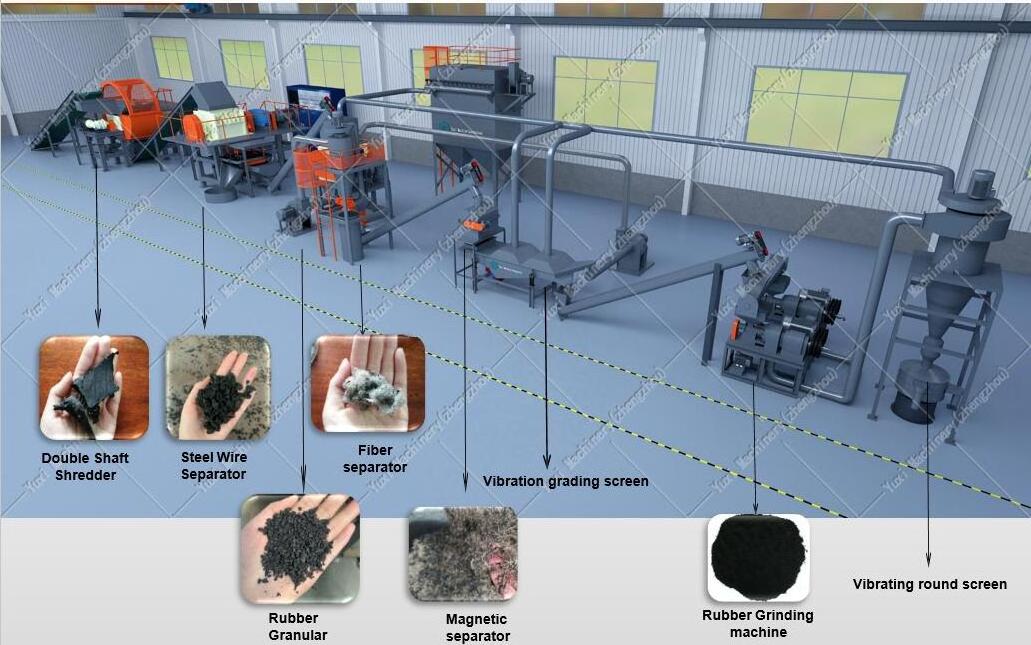

Tyre Recycling Machine

Yuxi waste tyre recycling machine, is a rare in the whole of the EU CE certification with high standard of quality certification.

The whole tyre recycling machine line can effectively realize the automatic separation of rubber, steel wire, nylon fiber and other materials, the whole line adopts PLC control system, it is easy to operate and maintain, and has the characteristics of low energy consumption and long service life.

Raw Materials

Raw materials: waste tires, rubber soles, waste pipes, rubber conveyor belts and other waste rubber products, of which waste tires are the most.

Application

What Is The Application of Used Tires?

Recycling of used tires after smashing has become a new industry hotspot and development trend.

The following product applications are for your reference

1.8-20 mesh, mainly used for runways, road cushions, sports pavements, etc.

2.30-40 mesh, mainly used for reclaimed rubber, paving, producing rubber sheets

3.40-60 mesh, mainly used for rubber rubber filling, plastic modification

4.60-80 mesh, mainly used in automobile tires, rubber products, building materials

Working Process

Working Process Flow

1.Conveyor-Transport the tire to the shredder;

2.

Double shaft shredder

---Shears the tire into 5-10 cm blocks;

3.Recirculation system---To control the size of shreds going to the raspers;

4

.Raspers

-Reduce the shreds into 15-20 mm chips and liberates steel from the rubber;

5.Over belt magnet--Separation of liberated steel from the rubber chips;

6.Vibratory feeder--Transports the rubber chips;

7.

Granulator

--Size reduction of the chips to 1-4 mm granules and liberates the textile fraction to air flow separation.

8.Vibratory screen-Sorts the granules by size and removes the majority of textile;

9.Classifer-Removal of remaining textile;

10.Drum magnet-Removal of remaining steel fines;

11.Central de-dusting unit--Remove dust and fines from the system and filter the air before returning it to the atmosphere.

Tire Wire Pulling Machine

Due to the strong pulling force of the cylinder, the whole wire is pulled out, and the sidewall part due to the role of the pull mouth, prompting the rubber tear, which played a smooth separation purposes.

Tyre Shredder Machine

The machine consists of rack,cavity, motor, hydraulic coupling, reducer, a group of moving blades, two sets of blades, screen, hydraulic system.

Steel Wire Separator

The basic principle of the motor driven, limited torque coupling driven by reducer, the power and the fixed knife to form the shear potential, the material through the screen to achieve the specifications of the pellet.

Rubber Milling Machine

It is a device that pulverizes 2-6 mm pure rubber particles into 40-200 mesh fine rubber powder at normal temperature.

The structure mainly includes: crushing motor, variable frequency feeding mechanism, grinding disc adjusting mechanism, adding hopper, moving grinding disc, body, main shaft, collecting tube, circulating water cooling system, and the like.

Technical Parameter

|

Raw Material

|

Tires

|

|

Feeding Size

|

1200mm diameter

|

|

Capacity

|

800-1000KG per hour

|

|

Discharge Size

|

0.5mm rubber granulates

|

|

Control Method

|

Automatic

|

|

Size of Equipment

|

500sqm

|

Configuration Line

|

No.

|

Content

|

Function

|

Power(kw)

|

|||

|

Steel Wire Removal Process

|

|

|

|

|||

|

1

|

Tire steel wire drawing machine

|

Vertical removal of tire inner steel wire equipment.

|

11

|

|||

|

Rubber Block Process

|

|

|

|

|||

|

2

|

Whole tire shredder

|

whole tire shredder

|

45*2

|

|||

|

Rubber Granular Process

|

|

|

45kw*2

|

|||

|

3

|

Separate steel wire machine

|

Smash the 50*50 mm rubber block into pieces and separate the steel wire.

|

45

|

|||

|

4

|

Rubber Granular

|

The separated rubber pellet fine shredder, shredder to <8mm

|

37

|

|||

|

Rubber Grinding Process

|

|

|

|

|||

|

5

|

Grinder Machine

|

Grinder machine

|

50

|

|||

|

Dust Removal Process

|

|

|

|

|||

|

6

|

Fiber separator

|

Separate the fiber in rubber powder and pellet

|

(5.5+7.5)

|

|||

|

7

|

Dust removal equipment

|

overcomes the shortcomings of the room dust cleaning intensity and the inhomogeneous distribution of inlet and outlet.

|

5.5

|

|||

Advantage

1.Complete Separation : The rubber Crumbs Steel and Fiber can be separated automatically.

2.Advanced Control System: Adopt PLC control system, it is simple and easy to control and maintain. For example, it is only need 4-6 persons to operate a tire recycling(granule)production line with 3000 kg/h capacity

3.Low Energy Consumption: The installed power of tire recycling production(granule) line with capacity 3000 kg/h is about 800 kw

4.Long service life, High utilization, Multiple maintenance.O Humanized design, safe and secure.

Project Case

Project Case

Our machines meet European standards, European customers have purchased our fully automatic tire production line, and managers and engineers have gone to Europe to help customers install the test machine.

Chilean customer installation site

.

Hot Searches