1) It has the characteristics of corrosion resistance, light weight, and high rigidity.which ensures high-speed movement during

laser processing.

2) It has perfect dynamic performance, such as anti-distortion, anti-overturning

anti-deformation, etc, ensuring higher cutting accuracy.

- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

WEIHONG

-

Cutting Area:

-

1515*3030mm 2020*4040mm 2525*6050mm

-

Cutting Thickness:

-

1-20mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DXTECH

-

Weight (KG):

-

5000 KG

-

Machinery Test Report:

-

Provided CE certificate

-

Product name:

-

Fiber Laser Metal plate Cutting Machine

-

Control system:

-

FSCUT cutting system

-

Driver system:

-

Fuji servo motor made in Japan

-

Liner guider system:

-

PMI made in Taiwan

-

Rack system:

-

VASTUN made in TAIWAN

-

Cooling Way:

-

Guangzhou TEYU

-

Pneumatic components:

-

SMC made in Japan

-

Electrical components:

-

Schneider made in France

-

Reducer:

-

SHIMPO

-

Bed frame:

-

High temperature quenching stress relief(Standard bed)

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

0-120M/Min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

WEIHONG

-

Cutting Area:

-

1515*3030mm 2020*4040mm 2525*6050mm

-

Cutting Thickness:

-

1-20mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DXTECH

-

Weight (KG):

-

5000 KG

-

Machinery Test Report:

-

Provided CE certificate

-

Product name:

-

Fiber Laser Metal plate Cutting Machine

-

Control system:

-

FSCUT cutting system

-

Driver system:

-

Fuji servo motor made in Japan

-

Liner guider system:

-

PMI made in Taiwan

-

Rack system:

-

VASTUN made in TAIWAN

-

Cooling Way:

-

Guangzhou TEYU

-

Pneumatic components:

-

SMC made in Japan

-

Electrical components:

-

Schneider made in France

-

Reducer:

-

SHIMPO

-

Bed frame:

-

High temperature quenching stress relief(Standard bed)

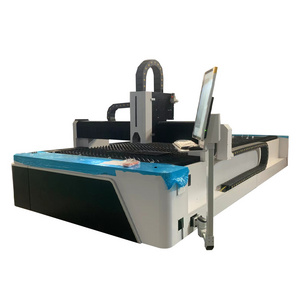

dxtech laser 1500*3000mm hot-sale sheet metal carbon steel CNC cutting fiber laser sheet cutting machine

Products Description

1. Simple operating system, to realize rapid cutting on the shape what you want on the metal material, like Steel, Iron, Aluminum Plate, Carbon steel, Stainless steel, Cooper, and galvanized sheet .

2.Independent control cabinet

1) Dust proof: all electrical components and laser sources are built in an independent control cabinet to prevent dust pollution.

2) Automatic thermostat: equipped with an automatic constant temperature air conditioner, which can prevent the damage to the components due to the high temperature.

3. Aviation aluminum alloy beam to ensure the running speed is up to 150m/min.

4. World-class components like guide rails and racks to guarantee the cutting accuracy.

5. The strong iron flatbed to keep the machine for 20 years without distortion.

6. When considering sheet metal laser cutting prices, laser cutting has a higher quality cutting edge, it saves money and time cost if we count all cost all.

2.Independent control cabinet

1) Dust proof: all electrical components and laser sources are built in an independent control cabinet to prevent dust pollution.

2) Automatic thermostat: equipped with an automatic constant temperature air conditioner, which can prevent the damage to the components due to the high temperature.

3. Aviation aluminum alloy beam to ensure the running speed is up to 150m/min.

4. World-class components like guide rails and racks to guarantee the cutting accuracy.

5. The strong iron flatbed to keep the machine for 20 years without distortion.

6. When considering sheet metal laser cutting prices, laser cutting has a higher quality cutting edge, it saves money and time cost if we count all cost all.

Aviation Aluminum Beam

Intelligent focusing laser head

Cooling: Both the collimating lens and the focusing lens group are cooling accessories. Besides, the cooling airflow nozzle is

added, which effectively protects the nozzle and the ceramics and prolongs the working time. Chasing Aperture: Through the 35 mm

aperture, the interference of stray light is effectively reduced. Autofocus: Without human interference, the focusing speed can

reach 10m/min, and the repeatability is about 50 microns.

added, which effectively protects the nozzle and the ceramics and prolongs the working time. Chasing Aperture: Through the 35 mm

aperture, the interference of stray light is effectively reduced. Autofocus: Without human interference, the focusing speed can

reach 10m/min, and the repeatability is about 50 microns.

Thick-walled carbon steel pipe welding bed

Adopting high-quality carbon steel welding bed, it is more stable and durable. The high-strength machine tool adopts 600 ℃ stress

relief annealing treatment, which has strong structural rigidity, small deformation, and low vibration to ensure cutting accuracy.

relief annealing treatment, which has strong structural rigidity, small deformation, and low vibration to ensure cutting accuracy.

Technical Paramenters

|

Model

|

DXTECH-1530FP

|

DXTECH-2040FP

|

DXTECH-2560FP

|

|

Machine size

|

4320*2250*1950mm

|

5350*2800*1950mm

|

5350*3350*1950mm

|

|

Working area

|

1515*3030mm

|

2020*4040mm

|

2525*6050mm

|

|

Positioning accuracy

|

±0.03mm

|

±0.03mm

|

±0.03mm

|

|

Repositioning accuracy

|

±0.02mm

|

±0.02mm

|

±0.02mm

|

|

Max. acceleration

|

1.5G

|

1.5G

|

1.5G

|

|

Laser power

|

1kW – 6kW

|

1kW – 6kW

|

1kW – 6kW

|

|

Laser

|

Multiple options

|

Multiple options

|

Multiple options

|

|

Focusing method

|

Auto/manual

|

Auto/manual

|

Auto/manual

|

|

Max. running speed

|

140m/min

|

140m/min

|

140m/min

|

Sample Show

Product Category

Hot Searches