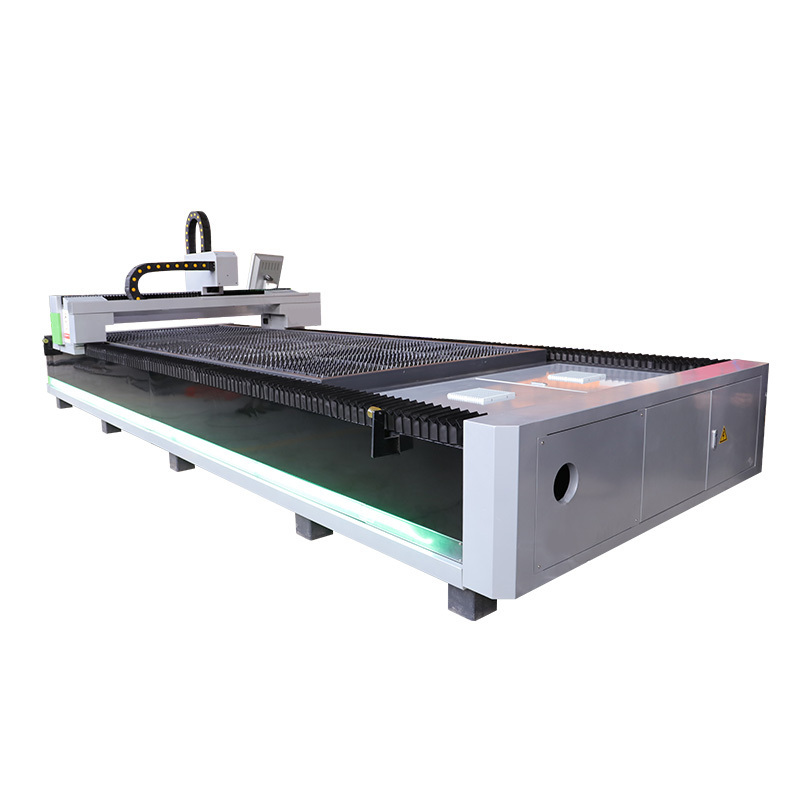

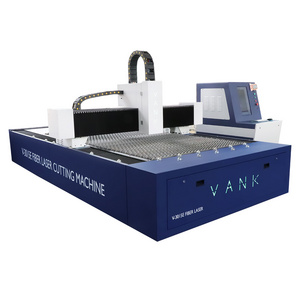

The machine frame is annealed and milled by a large gantry to accurately drill all installation basic holes at once.

Higher tensile strength and dimensional stability.

Effectively improve the accuracy of the bed, reduce the processing error of the workpiece. Increase the resistance and stability of the guide rail.

It reduces the loss of the equipment when it is used. It keeps the precision of the cheap laser cutter for a long time and does not deform for 20 years. The affordable laser cutter has

good stability

and reduces the processing errors caused by the vibration of the bed.