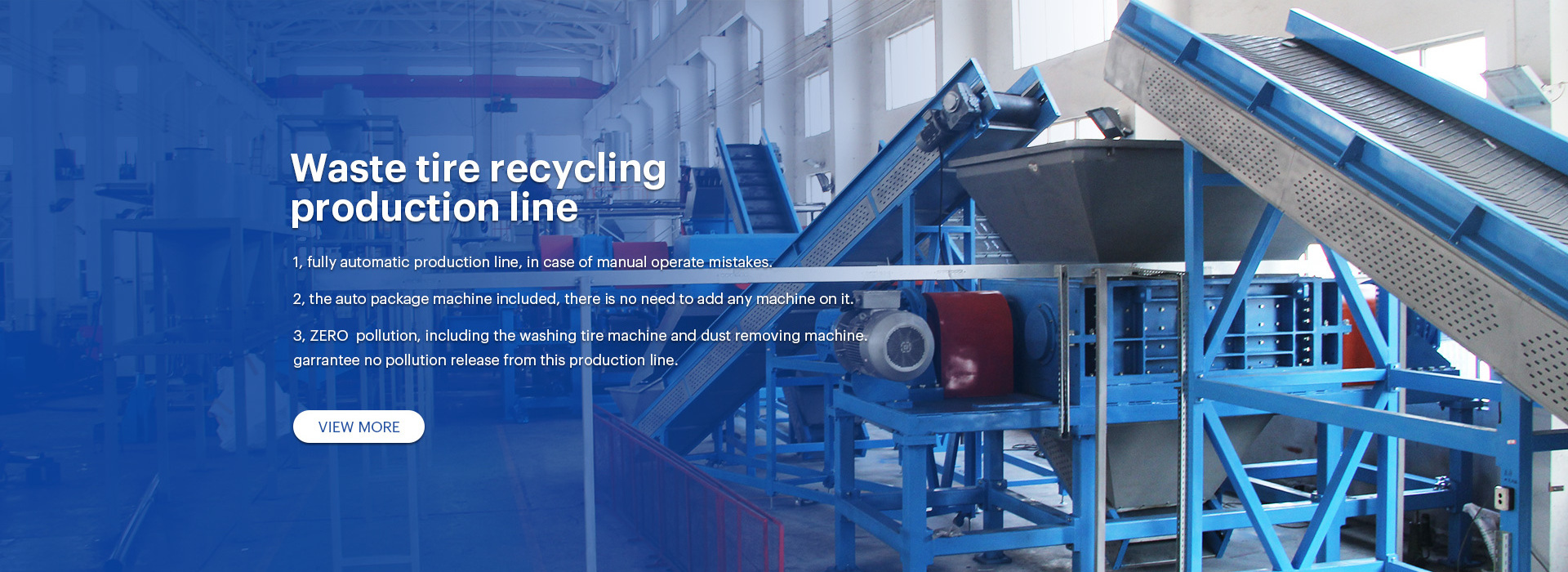

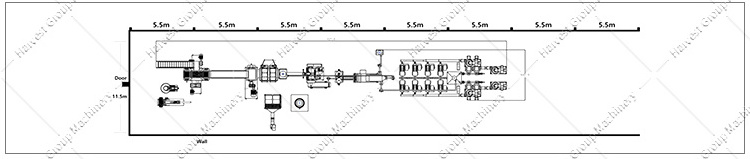

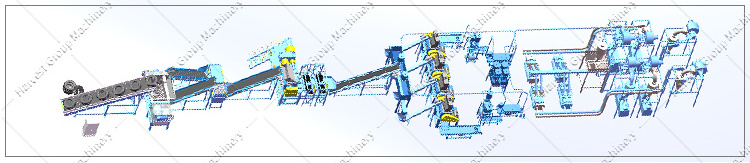

Waste Tire Recycling Rubber Granule Making Machine is adopting physical recycling method and is designed to grind the rubber mulch from the rasper into small granules as fine as 1-6mm. The granules are screened and re-circulated until the desired size is reached. This Fully-Automatic Tyre Recycling Line running in normal temperature, no need to add any other chemicals, no pollution to the environment. This is the best way to recycling scrap tires.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4.1X1.3X1.75M

-

Year:

-

2024

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

2000 KG

-

Name:

-

tire recycling plant price

-

Color:

-

Blue/green or as your requirments

-

Advantage:

-

Energy saving 1/3 compare with similar machines

-

Lead time:

-

20 days

-

Output::

-

40pcs/hour

-

Output:

-

1-10 tons/hour

-

Certificate:

-

CE/ISO

-

Keyword:

-

car tire recycling production line

-

Application:

-

Recycle waste tyre

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HVST

-

Voltage:

-

380V, Customers' request customized motor

-

Dimension(L*W*H):

-

4.1X1.3X1.75M

-

Year:

-

2024

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

2000 KG

-

Name:

-

tire recycling plant price

-

Color:

-

Blue/green or as your requirments

-

Advantage:

-

Energy saving 1/3 compare with similar machines

-

Lead time:

-

20 days

-

Output::

-

40pcs/hour

-

Output:

-

1-10 tons/hour

-

Certificate:

-

CE/ISO

-

Keyword:

-

car tire recycling production line

-

Application:

-

Recycle waste tyre

waste tire recycling machine tire/tyre shredder machine price in China

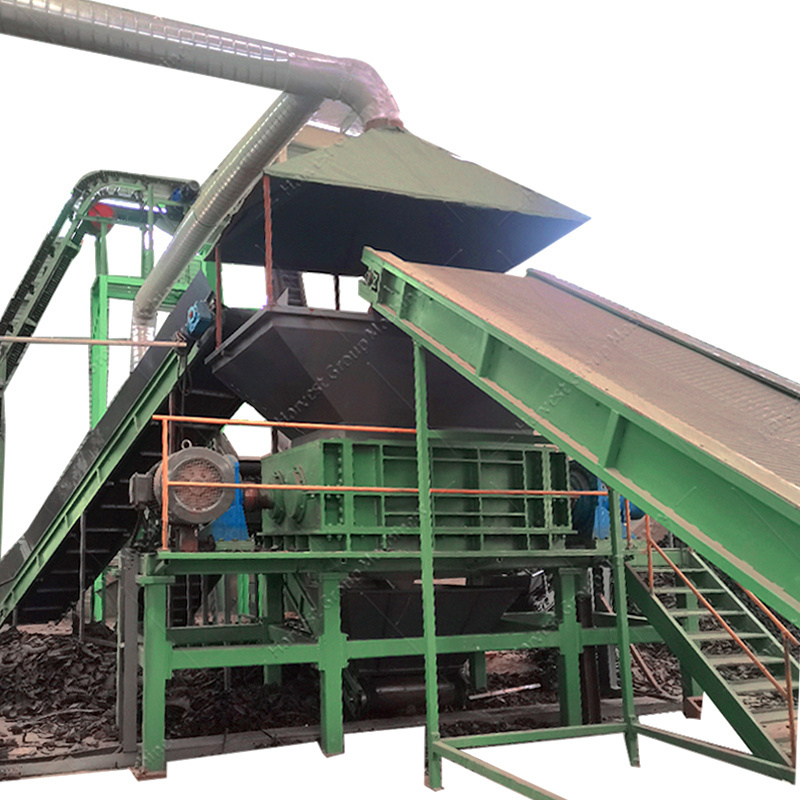

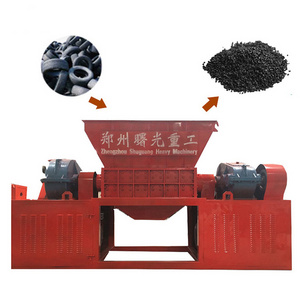

1.Tire shredder machine

The Rubber Shredder Machine adopt PLC automatic control system, with automatic reversal control system in overload condition. Two-shaft tire crusher is specially designed for old tires with low speed and high torque to minimize noise and power consumption.

The blade of the shredder is made of high quality steel and subjected to Bodycote heat treatment to achieve the best crushing performance.The shredder is easy to disassemble and change cutter blade and suitable for tearing large, extra thick and hard materials.The thickness range of the crushing blade is 25mm-152mm according to the tire type,output and final product. The grinder can process OTR tires,big truck tires,car tires and so on at the speed of 1-30tons whithin 1 hour.

|

Model

|

Input size

|

Output size

|

Cappacity

|

Motor

|

Blades quantity

|

Dimensions

|

Weight

|

|

TS-800

|

800mm

|

50*50mm

|

1-2T/h

|

2*22kw

|

16pcs

|

4*2.6*3.2m

|

8T

|

|

TS-1200

|

1200mm

|

60*60mm

|

3-5T/h

|

2*37kw

|

20pcs

|

4.8*2.8*3.5m

|

14T

|

|

TS-1600

|

1600mm

|

50-150mm

|

6-8T/h

|

2*45kw

|

16-30pcs

|

5*2*3.4m

|

18T

|

|

TS-1800

|

1800mm

|

50-150mm

|

7-10T/h

|

2*55kw

|

20-24pcs

|

5.6*2*3.4m

|

23T

|

|

TS-2000

|

2000mm

|

75-200mm

|

10-15T/h

|

2*75kw

|

20-30pcs

|

6*2.4*4m

|

36T

|

|

TS-2400

|

2400mm

|

100-200mm

|

20-30T/h

|

2*110kw

|

16-24pcs

|

7.4*3.2*5.2m

|

56T

|

2.Rasper

HVST tire shredding system is designed to produce up to 6 tons per hour of wire free rubber mulch.This system produces up to a 99% wire free chip ranging in size between 12-25mm depending on the desired size.After processing,the steel is removed by our magnetic separation system.At this point,the wire free rubber chips are ready to be colored and used for landscaping mulch and the steel is ready to be baled and sold to smelters.

|

Rasper

|

Motor

|

Power

|

Capacity

|

Dimensions

|

Weight

|

Cutting chamber

|

Final product

|

|

R45

|

Siemens

|

45KW

|

300-500kg/H

|

1.4*1.2*2.3m

|

1700kg

|

450*600mm

|

10-30mm

|

|

R55

|

Siemens

|

55KW

|

500-700kg/H

|

1.7*1.7*2.3m

|

1850kg

|

450*800mm

|

10-30mm

|

|

R75

|

Siemens

|

75KW

|

700-1T/H

|

2*2*4.1m

|

3500kg

|

550*800mm

|

10-30mm

|

|

R90

|

Siemens

|

90KW

|

1-1.5T/H

|

2.1*2.1*4.1m

|

4200kg

|

550*1000mm

|

10-30mm

|

|

R132

|

Siemens

|

132KW

|

1.5-3T/H

|

2*2.5*4.1m

|

6100kg

|

742*1200mm

|

10-30mm

|

|

R315

|

Siemens

|

315KW

|

3-6T/H

|

6.2*2.1*3.6m

|

12400kg

|

697*1562mm

|

10-30mm

|

3.Granulator machine

|

Granulator

|

G37

|

G45

|

G90

|

|

Motor

|

Siemens

|

Siemens

|

Siemens

|

|

Power

|

37kw

|

45kw

|

90kw

|

|

Capacity

|

300-500kg/h

|

500-800kg/h

|

800-1500kg/h

|

|

Dimensions

|

1.8*1.6*2.4m

|

1.8*1.9*2.4m

|

2.2*2.3*3m

|

|

Final product

|

1-6mm

|

1-6mm

|

1-6mm

|

4.Miller

Rubber powder is the final result of ambient tire recycling.At this stage,crumb rubber is ground down into a clean powder form with virtually all steel and fiber removed.Rubber powder has numerous secondary uses from injection molding products,coatings,roofing materials and various asphaltapplications.

Rubber powder is typically found in 40-74 microns(0.40-0.74mm) in size.This micron size metarial has the advantage of being incorporated into new or existing formulations for various polymers and finished products.

|

Rubber powder

|

M2000

|

M1500

|

M1000

|

M500

|

|||

|

Input product

|

Heavy duty truck tyres to bicycle tyres

|

|

|

|

|||

|

Input size

|

Diameter 1800mm

|

Diameter 1800mm

|

Diameter 1800mm

|

Diameter 1800mm

|

|||

|

Output size

|

shred to 30-120 mesh rubber powder

|

|

|

|

|||

|

Capacity

|

2000kg/h

|

1500kg/h

|

1000kg/h

|

500kg/h

|

|||

|

Total Kw

|

680-760kw

|

516-556kw

|

347-372kw

|

170-190kw

|

|||

Zhengzhou Harvest Machinery Co., Ltd

We are based in Henan, China, start from 2013,sell to South America(20.00%),Africa(20.00%),Southeast Asia(20.00%),North America(10.00%),Western Europe(10.00%),Eastern Europe(10.00%),Mid East(10.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Waste Tire Recycling Machine/Rubber Crusher/Tire Shredder/Tire Crusher/E-waste Recycling/Metal Shredder/Plastic Recycling/Cable Wire Recycling/Wood Shredder, Waste Tire Recycling Machine/Metal Shredder/PCB Recycling/Copper Wire Recycling/Plastic Recycling/Wood Shredder

4. why should you buy from us not from other suppliers?

1.Our factory established in 1987, With nearly 30 years experience 2. All machines are 2 years warranty 3. Competitive price with high quality 4.We got SGS inspection certificate and CE certificate 5. Factory visited is welcomed

5. what services can we provide?

Accepted Delivery Terms: FOB,EXW;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,Western Union,Cash;

Language Spoken:English,Chinese,Arabic,Korean