- Product Details

- {{item.text}}

Quick Details

-

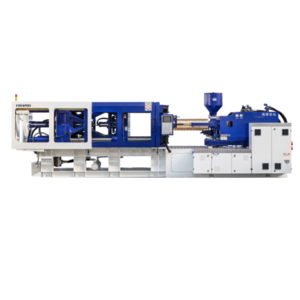

Product name:

-

Thin-Wall Injection Machine

-

Machine weight:

-

17T

-

Machine dimension(L*W*H):

-

7.3*1.9*2.7m

-

Screw diameter:

-

50/55mm

-

Voltage:

-

380V/ 50Hz 3P+N+E (alterable)

-

Heating power:

-

19kW

-

MOULD THICKNESS:

-

240-650mm

-

Ejector Stroke:

-

160mm

-

Injection Rate:

-

616/745g/s

-

Injection Weight:

-

436/528g

Quick Details

-

Injection Weight (g):

-

528 g

-

Screw diameter (mm):

-

55 mm

-

Place of Origin:

-

Zhejiang, China

-

Product name:

-

Thin-Wall Injection Machine

-

Machine weight:

-

17T

-

Machine dimension(L*W*H):

-

7.3*1.9*2.7m

-

Screw diameter:

-

50/55mm

-

Voltage:

-

380V/ 50Hz 3P+N+E (alterable)

-

Heating power:

-

19kW

-

MOULD THICKNESS:

-

240-650mm

-

Ejector Stroke:

-

160mm

-

Injection Rate:

-

616/745g/s

-

Injection Weight:

-

436/528g

Fast

HIGHER WORK EFFICIENCY

According to features of injection, optimize and integrate

injection, damping, hydraulic and control units, which has greatly shortened the production cycle.

STABLE

STRICTER SAFETY STANDARDS

Comply with national mandatory safety standard to

guarantee operators' safety.

ECONOMICAL

LOWER COST FOR OPERATION AND MAINTENANCE

Multi-action compound operation; high-speed low-pressure injection has improved production efficiency of thin-wall products; the application of high-quality materials

and mechanical structure of long services life have

greatly reduced the maintenance cost.

POWERFUL

MORE PERFECT ORGANIZATION STRUCTURE

Frame-type rack design; improve rigidity and strength on the basis of finite element analysis, which has greaUy

improved rack precision, reduced rack deformation and

realized a more stable and smooth operation.

|

ITEM

|

|

UNIT

|

DATA

|

|

|

|||

|

Injection Unit

|

Screw Diameter

|

mm

|

50

|

55

|

|

|||

|

|

Screw L/D Ratio

|

L/D

|

25

|

23

|

|

|||

|

|

Injection Volume

|

cm

3

|

480

|

580

|

|

|||

|

|

Shot Weight

|

g

|

436

|

528

|

|

|||

|

|

Injection Rate

|

g/s

|

616

|

745

|

|

|||

|

|

Injection Speed(max)

|

mm/s

|

350

|

|

|

|||

|

|

Injection Pressure

|

Mpa

|

169

|

140

|

|

|||

|

|

Screw Speed

|

RPM

|

350

|

|

|

|||

|

Clamping Unit

|

Clamping Force

|

KN

|

3600

|

|

|

|||

|

|

Opening Stroke

|

mm

|

640

|

|

|

|||

|

|

Space Between Tie-Bars

|

mm

|

715×715

|

|

|

|||

|

|

Mould Thickness(Min-Max)

|

mm

|

240-650

|

|

|

|||

|

|

Hydraulic Ejection

|

KN

|

102

|

|

|

|||

|

|

Ejector Stroke

|

mm

|

160

|

|

|

|||

|

General

|

System Pressure

|

Mpa

|

14

|

|

|

|||

|

|

Motor Power

|

KW

|

37×2

|

|

|

|||

|

|

Heater

|

KW

|

21

|

|

|

|||

|

|

Machine Dimension

|

m

|

7.3×1.9×2.7

|

|

|

|||

|

|

Machine Weight

|

t

|

17

|

|

|

|||

|

|

Mould Orientation Ring Diameter

|

mm

|

Φ160

|

|

|

|||

|

|

Nozzle Radius

|

mm

|

SR10

|

|

|

|||

Injection System

Clamping Systems

HYDRAULIC SYSTEM

CONTROL SYSTEM

HD260K

HD300K

HD420K

|

Model

|

Shot Weight (g)

|

Space Between bars (mm)

|

Model

|

Shot Weight (g)

|

Space Between bars (mm)

|