- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.4-0.8 mm

-

Place of Origin:

-

China

-

Brand Name:

-

ROOFTECH

-

Voltage:

-

380V 50Hz 3phases

-

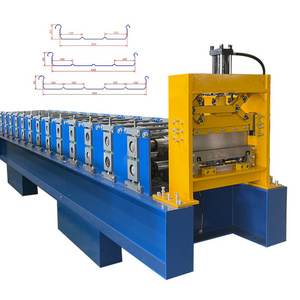

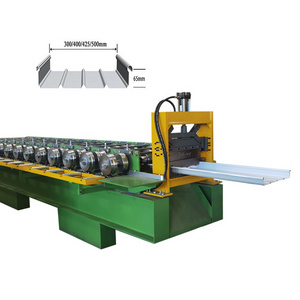

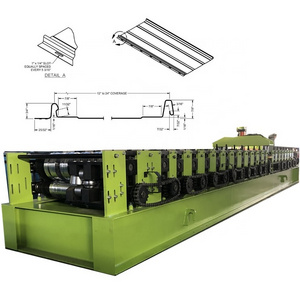

Dimension(L*W*H):

-

8000*1700*1600Mm

-

Weight:

-

6.5 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr12 Quenched

-

Shaft material:

-

High Grade No.45 Forged

-

Control system:

-

Siemens Control System

-

Plc:

-

Japanese Mitsubishi Programmale Controller

-

Usage:

-

Roof Panel

-

Raw material:

-

45#steel Chrome Plated

-

Product name:

-

roofing machine

Quick Details

-

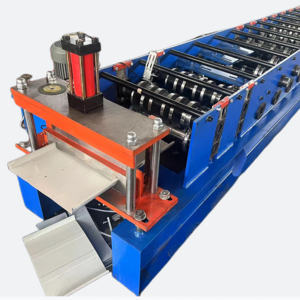

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

15-20m/min

-

Rolling thinckness:

-

0.4-0.8 mm

-

Place of Origin:

-

China

-

Brand Name:

-

ROOFTECH

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

8000*1700*1600Mm

-

Weight:

-

6.5 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr12 Quenched

-

Shaft material:

-

High Grade No.45 Forged

-

Control system:

-

Siemens Control System

-

Plc:

-

Japanese Mitsubishi Programmale Controller

-

Usage:

-

Roof Panel

-

Raw material:

-

45#steel Chrome Plated

-

Product name:

-

roofing machine

Product Description

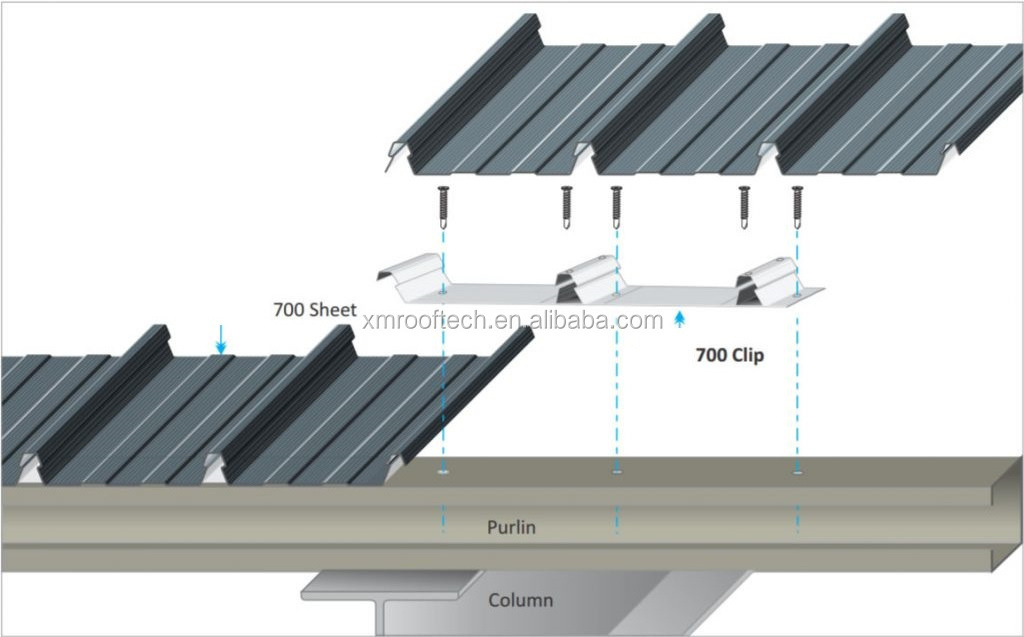

Product Application

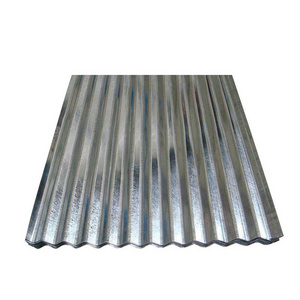

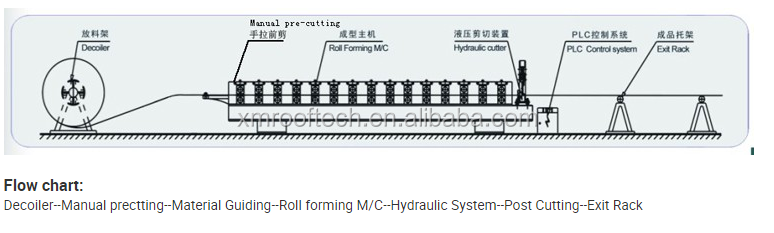

This machine takes GI/PPGI as raw material, through a series steps and can produce the metal roofing sheets . The inverter controls the motor speed, the PLC system controls length and quantity automatically, therefore, the machine achieves a continuous automatic production, which is the ideal equipment for cold roll forming industry.

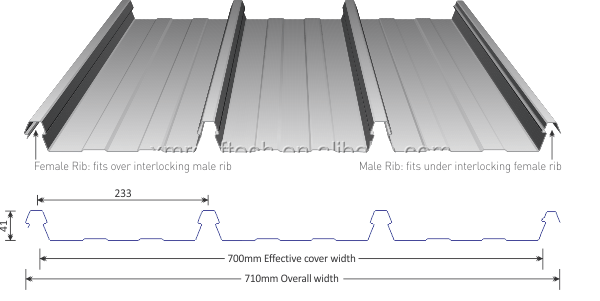

design

Product Show

factory show

Hot Searches