- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SICHENG

-

Model Number:

-

Zirconium Oxide Sand Ceramic sand B120

-

Usage:

-

Shot blasting media

-

Product name:

-

Ceramic beads

-

Application:

-

Blasting media

-

Color:

-

Yellow-white

-

Material:

-

Zr2O

-

Shape:

-

Round

-

Moh's hardness:

-

7

-

Specific Gravity:

-

4.3g/cm3

-

Bulk density:

-

2.1-2.3g/cm3

-

MOQ:

-

25KG

-

Sizes:

-

B20/B40/B60/B80/B100/B120/B150

Quick Details

-

Type:

-

blasting media

-

Abrasive Grain Sizes:

-

B120

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SICHENG

-

Model Number:

-

Zirconium Oxide Sand Ceramic sand B120

-

Usage:

-

Shot blasting media

-

Product name:

-

Ceramic beads

-

Application:

-

Blasting media

-

Color:

-

Yellow-white

-

Material:

-

Zr2O

-

Shape:

-

Round

-

Moh's hardness:

-

7

-

Specific Gravity:

-

4.3g/cm3

-

Bulk density:

-

2.1-2.3g/cm3

-

MOQ:

-

25KG

-

Sizes:

-

B20/B40/B60/B80/B100/B120/B150

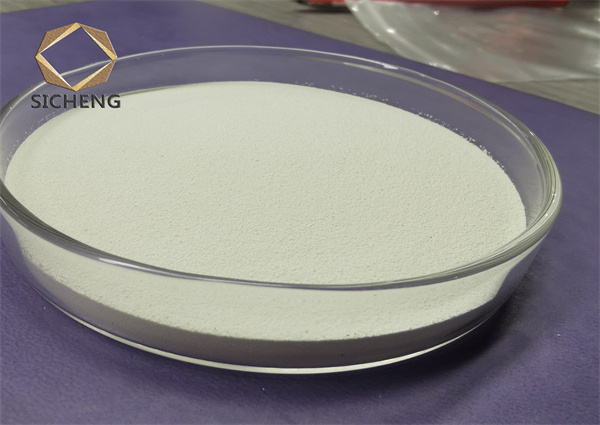

Zirconium Oxide Sand Ceramic sand B120

Production Introduction

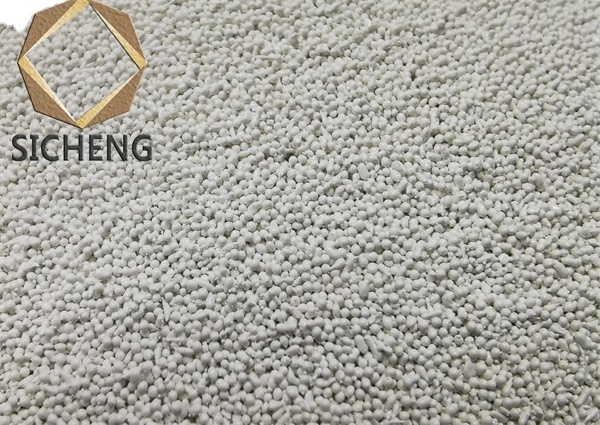

Ceramic bead is one round solid blasting media,it is able to replace glass beads when sandblasting for metal surface and plastic parts. Compared with glass beads,ceramic beads is not easy to be broken and little dust generated in blasting process,it will provide one clean working condition as well as more consistent visual effect after blasted. It has lower wear rate at 0.5-1.0kg per hour.Therefore it is also one economic and high efficient blasting media.

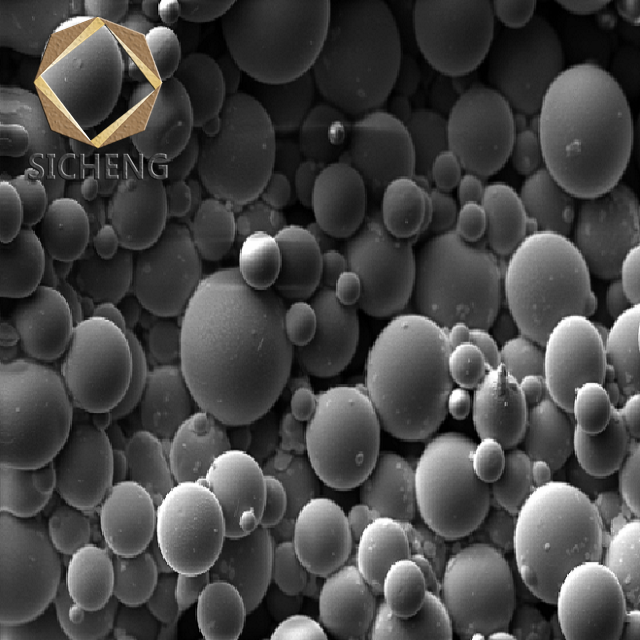

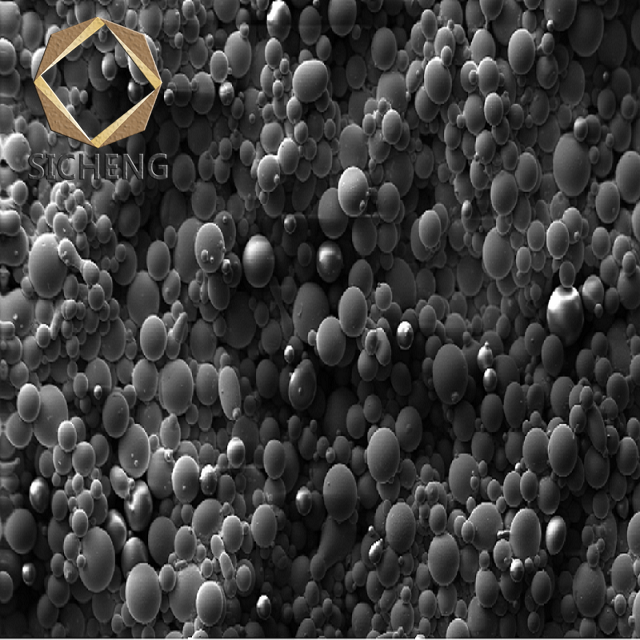

The main component of ceramic beads is zirconia, which is mainly used for surface treatment such as sand blasting and shot peening. The production process of ceramic shot is to melt high-quality imported zircon sand into liquid at high temperature, and then spray it into balls. The zirconia ceramic spheres are sieved and removed by magnetic separation to obtain particles with high roundness, high strength and uniform particle size. The spherical particles of ceramic shot can achieve better surface brightness during sandblasting, while the workpiece itself does not change color. It is widely used for sandblasting and surface treatment of aviation parts, stainless steel plates, structural parts, stainless steel kitchenware, medical devices, mobile phone / laptop shell, automobile chassis / engine, sports equipment and other industries.

F eatures

1. High strength and wear resistance. The main component of ceramic shot is zirconia, which is characterized by small crystal size and high wear resistance.

2. Ceramic shot has high hardness, with Vickers hardness (microhardness) of 700hv and Rockwell hardness of 600hrc. The density and specific gravity are also much higher than those of glass beads.

3. No dust, high abrasion resistance and strength make it difficult for ceramic shot to be broken during sand blasting, so it is not easy to generate dust.

4. Sandblasting effect: the surface finish is high. Using ceramic shot sandblasting can achieve smooth satin surface brightness. Using ceramic shot of the same specification is 60-70% lower than that of glass bead sandblasting.

5. It is applicable to various metals and nonmetals, such as titanium alloy, magnesium alloy, aluminum alloy, stainless steel, carbon steel, brass and alloy, acrylic, plastic and other materials. Ceramic shot will not react or oxidize with metal, and there is no metal residue, so it will not affect the color of the workpiece.

6. It is suitable for dry blasting and wet blasting. The surface of ceramic shot is very smooth, and the wear of sand blasting equipment is very small.

7. Ceramic shot has high sandblasting efficiency and long service life, and its recycling times can reach 25 times of glass beads.

8. The roundness is high, and the proportion of abnormal balls and snowman balls adhered between the spheres is low.

Chemical composition

|

Chemical |

Typical value(%) |

Value range(%) |

|

ZrO2 |

63.80 |

60-70 |

|

SiO2 |

26.82 |

28-33 |

|

AL2O3 |

9.08 |

Max 10 |

|

Fe2O3 |

0.03 |

Max 0.1 |

|

TiO2 |

0.24 |

Max 0.4% |

P hysical properties

|

Mohs Hardness |

7.0 |

|

Vickers Hardness/ Rockwell hardness |

700HV/60HRC |

|

Specific gravity |

4.30g/cm3 |

|

Bulk density |

Size >125um:2.30g/cm3,size<125um:2.1-2.2g/cm3 |

Available sizes

|

Specification |

Particle size range |

|

B20 |

600-850 um |

|

B30 |

425-600 um |

|

B40 |

250-425 um |

|

B60 |

125-250 um |

|

B80 |

180-250 um |

|

B100 |

125-180 um |

|

B120 |

63-125 um |

|

B125 |

0-125 um |

|

B170 |

45-90 um |

|

B205 |

0-63 um |

|

B400 |

30-63 um |

|

B500 |

10-30 um |

*Other customized sizes are available.

Product application s

1. Medical treatment: surface treatment such as deburring of stainless steel surgical instruments and titanium alloy human implanted devices.

2. High iron field: it can be used for sandblasting the surface of high iron aluminum alloy parts to improve the metal texture and form a smooth satin effect. Used for grinding and finishing of high-speed rail.

3. Automotive field: ceramic shot can be used for surface cleaning and deburring of Automotive Engine Castings; It is used to clean the welds and welding spots on the car floor and prepare for subsequent spraying; Used for shot peening of automobile springs to improve fatigue life. It is used for beautification and sandblasting of aluminum alloy automobile wheels to eliminate stress and improve impact resistance.

4. Mold and machining: used for sand blasting of stainless steel mold, copper mold and aluminum alloy mold, such as tire mold, injection mold and stamping mold, to improve surface finish. Clean the flash and burr of machined parts.

5. Electronic equipment field: ceramic shot is used for sandblasting the shells of mobile phones, tablet computers and watches made of aluminum alloy or stainless steel. It can adjust the roughness and gloss of the surface as required, and has the characteristics of anti fingerprint.

6. Kitchen utensils industry: it is used for sandblasting of high-quality stainless steel cookware, pot bottom, soup spoon and other products, giving the products delicate metal texture and certain antibacterial ability.

7. Glass products industry: used for atomization treatment of glass, replacing hydrofluoric acid chemical etching process to prevent pollution.

8. Shot peening of aviation parts: used to improve the fatigue resistance of carbon steel, titanium alloy, aluminum alloy and other aviation mechanical parts and eliminate surface stress. It can be used for surface strengthening of aircraft wings, aeroengine turbine blades, turbine discs, gears and landing gear.