- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

3.6t

-

Name:

-

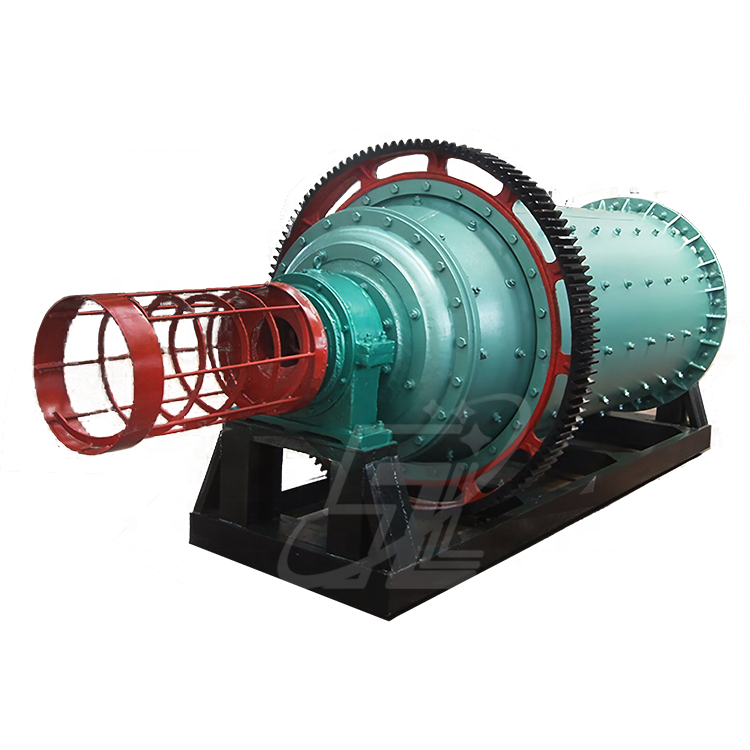

Gold Grinder Ball Mill

-

Installation:

-

Engineer's Guide

-

Application:

-

Stone Powder Grinding

-

The Machines classification:

-

Micron Milling Machines

-

After sale service:

-

Life-long Service

-

Grinding way:

-

Roller Grinding

-

Spare parts supplying:

-

Life Long Provide

-

Color:

-

Customer Requirement

-

Quality:

-

High Level

-

Model:

-

Grinding Ball Mill Machine

-

Certification:

-

CE, ISO

Quick Details

-

Capacity(t/h):

-

0.65-2

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

shunzhi

-

Weight:

-

3.6t

-

Name:

-

Gold Grinder Ball Mill

-

Installation:

-

Engineer's Guide

-

Application:

-

Stone Powder Grinding

-

The Machines classification:

-

Micron Milling Machines

-

After sale service:

-

Life-long Service

-

Grinding way:

-

Roller Grinding

-

Spare parts supplying:

-

Life Long Provide

-

Color:

-

Customer Requirement

-

Quality:

-

High Level

-

Model:

-

Grinding Ball Mill Machine

-

Certification:

-

CE, ISO

Prosess Description

The ball mill is a cylinder tube mill, which is characterized by high grinding efficiency single large capacity, low power

consumption and little dust pollution. It is commonly used in closed-circuit milling and open flow milling in the field of cement,fly ash, a variety of non-metallic materials dry milling production.

consumption and little dust pollution. It is commonly used in closed-circuit milling and open flow milling in the field of cement,fly ash, a variety of non-metallic materials dry milling production.

Principle

Working principle

The ball mill is horizontal cylindrical rotation device,driving by brim gearwheel, there are two chambers and grid. Material goes into the first chamber through the feeding inlet, inside the first chamber, there are stage liners and ripple liners as well as steel balls with various kinds.The shell rotates which generates eccentricity, this force brings balls to a certain height and then balls drop down by gravity, which will impact and grind the material. After the primary grinding in the first chamber, material goes into the second chamber through segregate screen, in the second chamber, there are fiat liners and steel balls,after the secondary grinding, material is discharged through the discharge screen.

The ball mill is horizontal cylindrical rotation device,driving by brim gearwheel, there are two chambers and grid. Material goes into the first chamber through the feeding inlet, inside the first chamber, there are stage liners and ripple liners as well as steel balls with various kinds.The shell rotates which generates eccentricity, this force brings balls to a certain height and then balls drop down by gravity, which will impact and grind the material. After the primary grinding in the first chamber, material goes into the second chamber through segregate screen, in the second chamber, there are fiat liners and steel balls,after the secondary grinding, material is discharged through the discharge screen.

Spare Parts

Main features

1. The lining can be replaced.

2. Mineral ball mill is an efficient tool for grinding many materials into fine powder.

3.Two ways of grinding: the dry way and the wet way.

4.Ultimate particle size depends entirely on how hard the material you’re grinding is.

5. As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

1. The lining can be replaced.

2. Mineral ball mill is an efficient tool for grinding many materials into fine powder.

3.Two ways of grinding: the dry way and the wet way.

4.Ultimate particle size depends entirely on how hard the material you’re grinding is.

5. As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

Parameters

|

Model

|

Effective Volume

(m3) |

Balls Weight

(t) |

Feeding Size

(mm) |

Capacity

(t/h) |

Main Reducer

|

|

φ1200*4500

|

4.7

|

6.5

|

≤25

|

1.4-2

|

ZD30

|

|

φ1500*5700

|

9.4

|

13

|

≤25

|

3.5-4.5

|

ZD40

|

|

φ1830*6400

|

15.7

|

21.6

|

≤25

|

5.5-6.5

|

ZD60

|

|

φ1830*7000

|

17.1

|

23.5

|

≤25

|

6-7

|

ZD60

|

|

φ2200*6500

|

23

|

31.5

|

≤25

|

8-10

|

ZD70

|

|

φ2200*7500

|

26.5

|

36

|

≤25

|

10-11

|

ZD70

|

|

φ2200*8000

|

28.3

|

39

|

≤25

|

10-12

|

ZD70

|

|

φ2400*11000

|

46.3

|

64

|

≤25

|

19-21

|

ZD80

|

|

φ2400*13000

|

54.7

|

75.5

|

≤25

|

21-23

|

MBY710

|

|

φ2600*13000

|

88.6

|

122

|

≤25

|

28-32

|

MBY800

|

|

φ3000*12000

|

78.9

|

109

|

≤25

|

32-35

|

MBY900

|

|

φ3000*13000

|

85.5

|

118

|

≤25

|

34-37

|

MBY900

|

|

φ3200*13000

|

134.2

|

185

|

≤25

|

45-50

|

MBY1000

|

|

φ3800*13000

|

137.1

|

189

|

≤25

|

60-62

|

MFYX250

|

|

φ4200*13000

|

167.5

|

231

|

≤25

|

85-87

|

MFX355

|

Applications

Why Choose Us

Customers Reviews

About SHUNZHI

Hot Searches