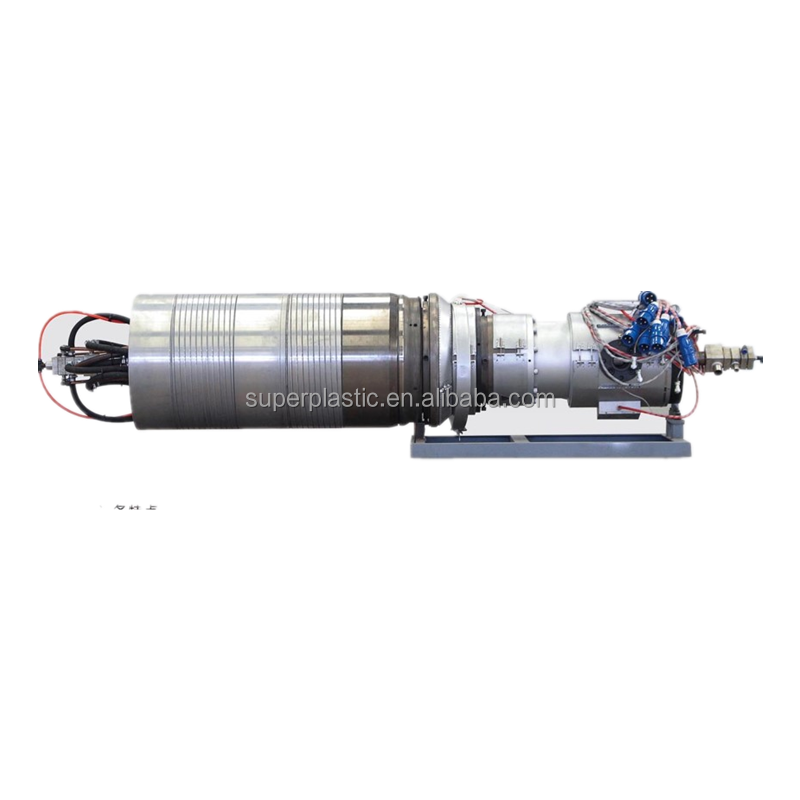

No need to loosen or tighten the tightening screws,just adjust the adjusting screws when adjust the thickness deviation.The short

flow channel of die head achieves low temperature and low pressure extrusion.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Power:

-

133kw

-

Dimension(L*W*H):

-

27m*3.5m*2.8m

-

Weight:

-

25000 kg

-

Keyword:

-

Pipe Production Line

-

Raw material:

-

HDPE PP PE

-

Usage:

-

Drainage

-

Pipe diameter:

-

ID90mm to ID300mm

-

Control system:

-

PLC

-

Thickness:

-

can be customized

-

Key word:

-

High speed

-

Production speed:

-

1.5-10m/min

-

Feature:

-

High automation

-

Pipe application:

-

water collection

Quick Details

-

Pipe Material:

-

PE/PP/HDPE/LDPE

-

Production Capacity:

-

10m/min

-

Place of Origin:

-

Shandong China

-

Voltage:

-

380v

-

Power:

-

133kw

-

Dimension(L*W*H):

-

27m*3.5m*2.8m

-

Weight:

-

25000 kg

-

Keyword:

-

Pipe Production Line

-

Raw material:

-

HDPE PP PE

-

Usage:

-

Drainage

-

Pipe diameter:

-

ID90mm to ID300mm

-

Control system:

-

PLC

-

Thickness:

-

can be customized

-

Key word:

-

High speed

-

Production speed:

-

1.5-10m/min

-

Feature:

-

High automation

-

Pipe application:

-

water collection

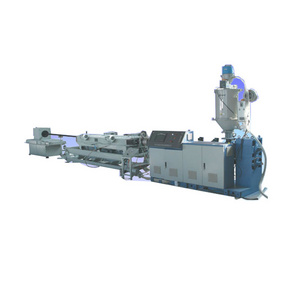

Product overview

SUBA machinery production line uses high speed closed loop recycled water cooling technology(Patented technology), optimized extruder with single bimetallic screw(L/D ratio:36:1), automatic cutter and so on, ensures our product have high speed, stable operation, lower power consumption, easy maintenance. And it could save you much money at the labor and power cost.

Product Description

Suba SL300 corrugated pipe extrusion line produces double layer corrugated pipes from ID90mm to ID300mm. All the moulds have cooling water inside for continuous cooling, horizontal structure ensures lower operation center height which achieves easier operation.

Main characteristics:

1. Water cooling- High speed;

2. Invention patents + Lower energy consumption+ Easy operation system;

3. Excellent after sales service + 24 hours online support system.

1. Water cooling- High speed;

2. Invention patents + Lower energy consumption+ Easy operation system;

3. Excellent after sales service + 24 hours online support system.

The extruder

The screw L/D ration is 36:1,has better plasticization;The gearbox adopts vertical and integrated structure,better quality.

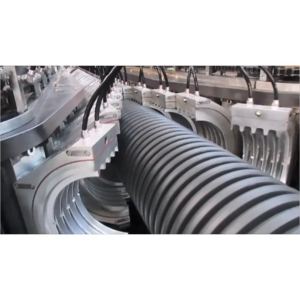

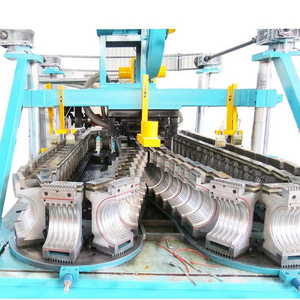

The corrugator

1,No platform design.

Patented closed loop water cooling systerm

2,Patented mould cooling system;

3,One time installation of the water pipe,No need to disassemble the water tubes when change the moulds.

Patented closed loop water cooling systerm

2,Patented mould cooling system;

3,One time installation of the water pipe,No need to disassemble the water tubes when change the moulds.

Die head

The cooling tank

Stainless steel,three-dimensional spray.

Runs synchronously with the corrugator.

Environmentally friendly: water is totally recycled.

The cutter

Innovative advanced trigger device of cutter guarantees accurate pipes cutting

The stacker

The system weighes,counts and turns over automatically,the number could be loaded to the computer for easy management.

Specification

|

item

|

value

|

|

Applicable Industries

|

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction works , Energy & Mining

|

|

Showroom Location

|

Russia, Kazakhstan, Kyrgyzstan, Uzbekistan

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

Ordinary Product

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

|

|

Condition

|

New

|

|

Type

|

Pipe Production Line

|

|

Pipe Material

|

PE/PP/HDPE/LDPE

|

|

Application

|

Drain Pipe

|

|

Production Capacity

|

10m/min

|

|

Place of Origin

|

Shandong China

|

|

Voltage

|

380v

|

|

Power

|

133kw

|

|

Dimension(L*W*H)

|

27m*3.5m*2.8m

|

|

Weight

|

25000kg

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

Long Service Life

|

Packing & Delivery

Packing Details: The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

Port: Qingdao Port

Lead Time: 105-115 days

Hot Searches