- Product Details

- {{item.text}}

Quick Details

-

Material:

-

65Mn, 60Si2Mn, C45, 40Mn, 40MnB, T9, T10

-

Colour:

-

black, yellow, natural etc.

-

Thichness:

-

3mm - 6.5mm

-

Edge hardness:

-

45 - 58 HRC

-

Knife hardness:

-

25 - 30 HRC

-

Surface:

-

anti-rust oil; varnish stoving; galvanized; Chrome finish

Quick Details

-

Weight (KG):

-

4 KG

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Combine

-

Material:

-

65Mn, 60Si2Mn, C45, 40Mn, 40MnB, T9, T10

-

Colour:

-

black, yellow, natural etc.

-

Thichness:

-

3mm - 6.5mm

-

Edge hardness:

-

45 - 58 HRC

-

Knife hardness:

-

25 - 30 HRC

-

Surface:

-

anti-rust oil; varnish stoving; galvanized; Chrome finish

|

|

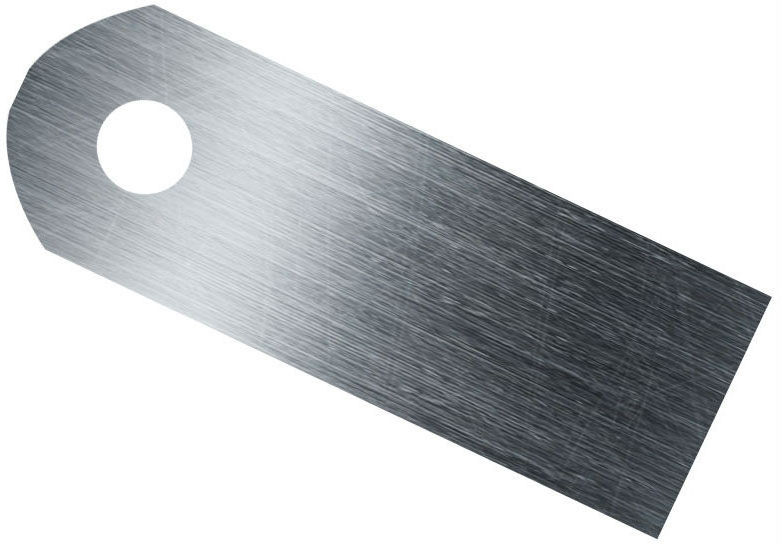

Quality point for the rotor knife :

1. The weight tolerance between different blades must be ± 6g, to keep the Stable Ratation.

2. How to keep good quality:

1) cut the raw material according to the pattern of steel, and the blade length direction must be along the pattern such as below, or it will be easily brocken;

2) Heat treatment: Firstly, increase the hardness by integral quenching, then tempering to 25-30 HRC, finally add the cutting edge hardness to 50-55HRC by high-frequency quenching.

We use salt bath quenching, by which the temperature is more homogeneous

3) Chambering in the hole or add a bushing in the hole. That's because the hold is tapered after the punching, it will abrade the hold the matched parts.

4) Good package to guarantee the quality during shipment

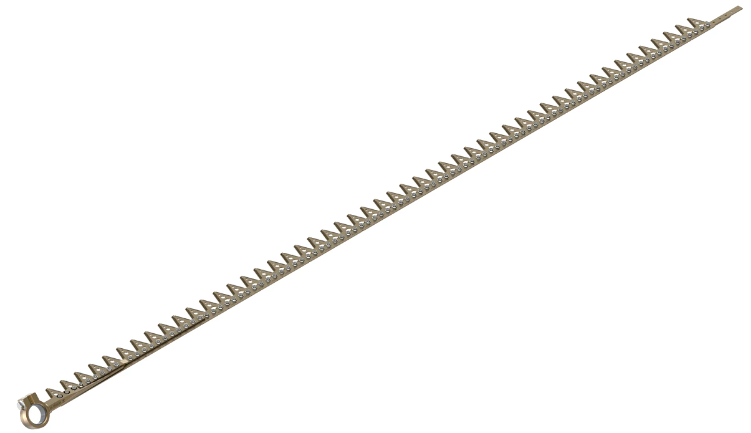

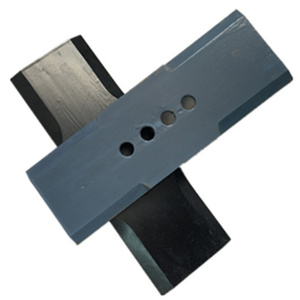

Other kind of straw choper knife: