- Product Details

- {{item.text}}

Quick Details

-

No. of Slitting Lines:

-

8 - 20

-

Coil Weight (T):

-

12 T

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

MC

-

Voltage:

-

380 V / 50 HZ, 380V, 3phase, 50Hz

-

Rated Power:

-

360

-

Dimension(L*W*H):

-

20*5*2.5

-

Weight:

-

70000

-

Year:

-

2022

-

Precision of slitting:

-

width±0.10 mm

-

Slitting speed:

-

150 m/min

-

Inner diameter of coiler:

-

508/610 mm

-

Outer diameter of coiler:

-

≤ 1850 mm

-

Slitting number(Max.):

-

20pcs

-

Slitting material width:

-

≥30 mm

-

Total power of machine:

-

230Kw

-

Max. recoil weight:

-

≤12t

-

Slitting blade strength:

-

HRC55

Quick Details

-

Cutting Width (mm):

-

500 - 1250 mm

-

Material Thickness(mm):

-

0.3 - 3 mm

-

Cutting Speed(m/min):

-

145 - 150 mm

-

No. of Slitting Lines:

-

8 - 20

-

Coil Weight (T):

-

12 T

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

MC

-

Voltage:

-

380 V / 50 HZ, 380V, 3phase, 50Hz

-

Rated Power:

-

360

-

Dimension(L*W*H):

-

20*5*2.5

-

Weight:

-

70000

-

Year:

-

2022

-

Precision of slitting:

-

width±0.10 mm

-

Slitting speed:

-

150 m/min

-

Inner diameter of coiler:

-

508/610 mm

-

Outer diameter of coiler:

-

≤ 1850 mm

-

Slitting number(Max.):

-

20pcs

-

Slitting material width:

-

≥30 mm

-

Total power of machine:

-

230Kw

-

Max. recoil weight:

-

≤12t

-

Slitting blade strength:

-

HRC55

Contacts: Mark Liu

Tel: +86-411-82766928

Fax: +86-411-39015062

Email: Liu@mingchenggroup.com

Mob/Whatsapp: +86 133 9411 0095

Products Description

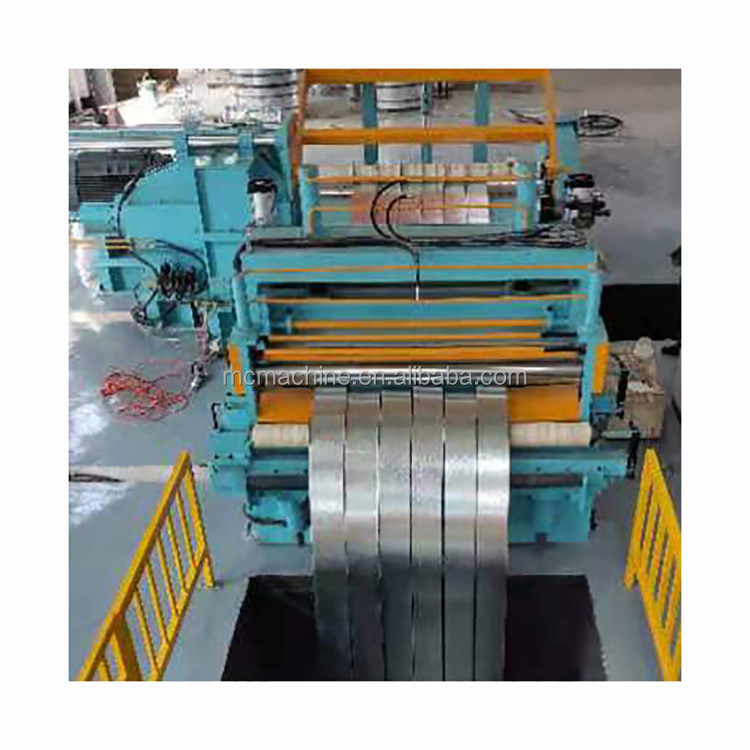

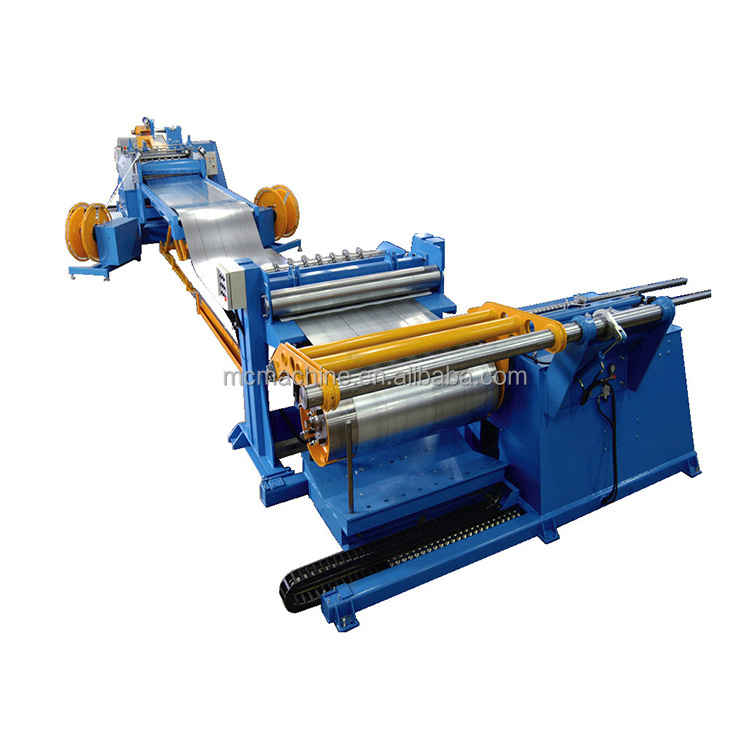

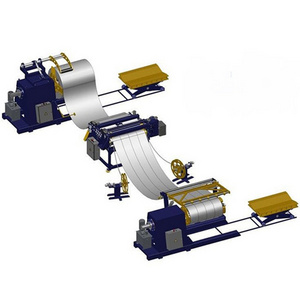

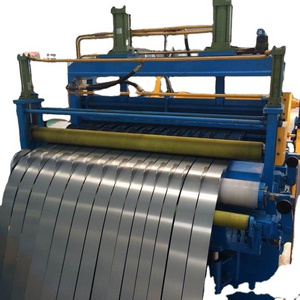

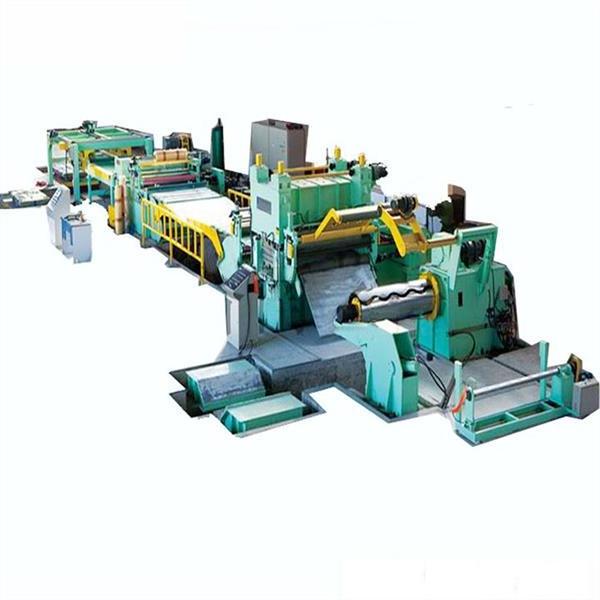

Cold-rolled uncoiling-slitting-winding production line

It is used for uncoiling, slitting and winding metal coils into coils of desired width. It is suitable for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel and various metal materials after surface coating.

Automatic uncoiler

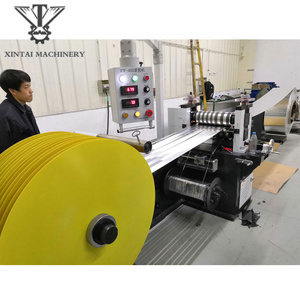

Slitting machine

production line

Cold-rolled uncoiling-slitting-winding production line

Slitting machine structure and features:

1. The slitting machine consists of a base, a main shaft part, an adjustment mechanism, a power part, a sliding seat, a gear box,a universal coupling, etc.

2. The base part mainly includes a fixed base, a movable base, and a motor bracket. It is welded by steel plate, and the aging treatment after welding has good rigidity and no deformation.

3. The guide device is mainly composed of

left and right sliders, worm gears and worms. Using the slider structure can greatly reduce the gap of the guide mechanism, so that the axial movement of the main shaft is less than 0.1mm, and the radial gap is also less than 0.03mm. The stability of the spindle is improved, and the shearing accuracy is guaranteed.

4. The transmission part consists of AC motor, gearbox, universal coupling, etc. Low noise, stable transmission, high efficiency and long life.

5. The sliding seat can be moved on the base with the sliding rail driven by the motor, which is convenient to replace the cutter head, cutter pad and spacer.

6.The lubrication system includes thin oil lubrication system and dry oil lubrication system, and the reduction box adopts its own

thin oil lubrication.

thin oil lubrication.

7. Operation function: accurately trim or divide the steel coil into steel plates of various

specifications.

8. Using disc knife to roll shear.

9.The upper and lower cutter shafts are respectively supported in the two bushings on the movable support of the frame and the fixed support, and the cutting amount of the blade can be adjusted by adjusting the worm gear and worm to change the distance between the cutter shafts.

10.By replacing the combined spacer, the width requirements of the finished board can be met.

Product Paramenters

|

Material:

|

MC-Q235

|

|

Thickness:

|

δ=0.3~3.0mm

|

|

Width:

|

500~1250mm

|

|

Precision of slitting :

|

width±0.10 mm

|

|

Slitting speed:

|

150 m/min

|

|

Uncoil loading weight:

|

≤12t

|

|

Inner diameter of coiler:

|

¢508/610 mm

|

|

Outer diameter of coiler :

|

≤¢1850 mm

|

|

Slitting blade shaft specification:

|

¢200 mm

|

|

Slitting number(Max.):

|

20pcs

|

|

|

0.3—1.2 mm: 20 pcs

|

|

|

1.2—2.0 mm: 20-12 pcs

|

|

|

2.0—3.0 mm: 12-8 pcs

|

|

Slitting material width:

|

≥30 mm

|

|

Slitting blade specification:

|

¢200×¢320×δ15 mm

|

|

Slitting blade material:

|

H13、SKD11

|

|

Slitting blade strength:

|

HRC55

|

|

.Recoil inner diameter:

|

¢508±20

|

|

.Max. recoil weight :

|

≤12t

|

|

Total power of machine:

|

230Kw

|

|

Overall dimension of machine: L:

|

about 32000mm W: about 7000mm

|

|

Voltage:

|

380V, 3phase, 50Hz

|

Recommend Products

Hot Searches