- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

11000*950*1300 mm

-

Weight:

-

1500 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V/380V

-

Power:

-

24kw, 1.1KW

Quick Details

-

Machinery Capacity:

-

500kg

-

Brand Name:

-

QD

-

Year:

-

2023

-

Dimension(L*W*H):

-

11000*950*1300 mm

-

Weight:

-

1500 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V/380V

-

Power:

-

24kw, 1.1KW

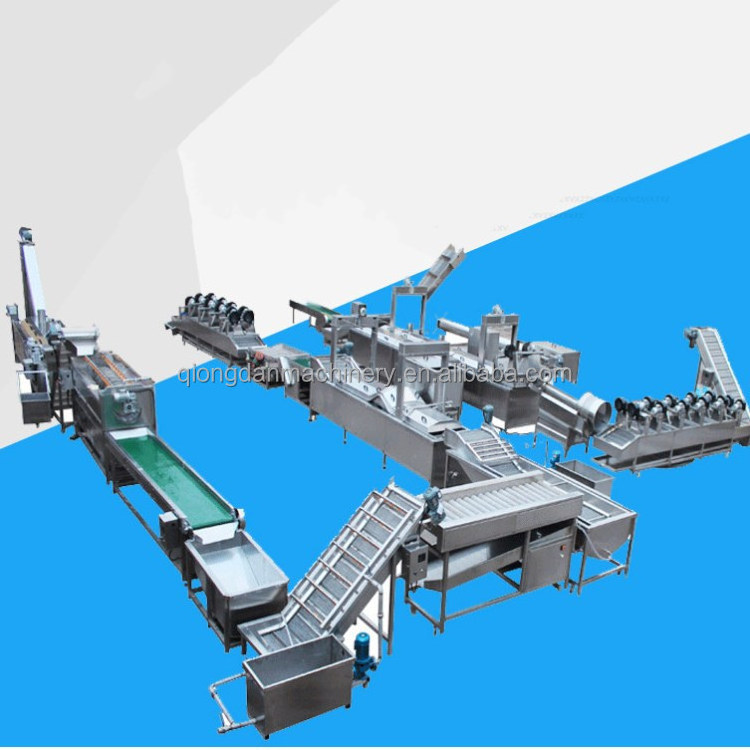

Whole frozen french fries production line from washing peeling to packing machiine to make potato chips price on sale

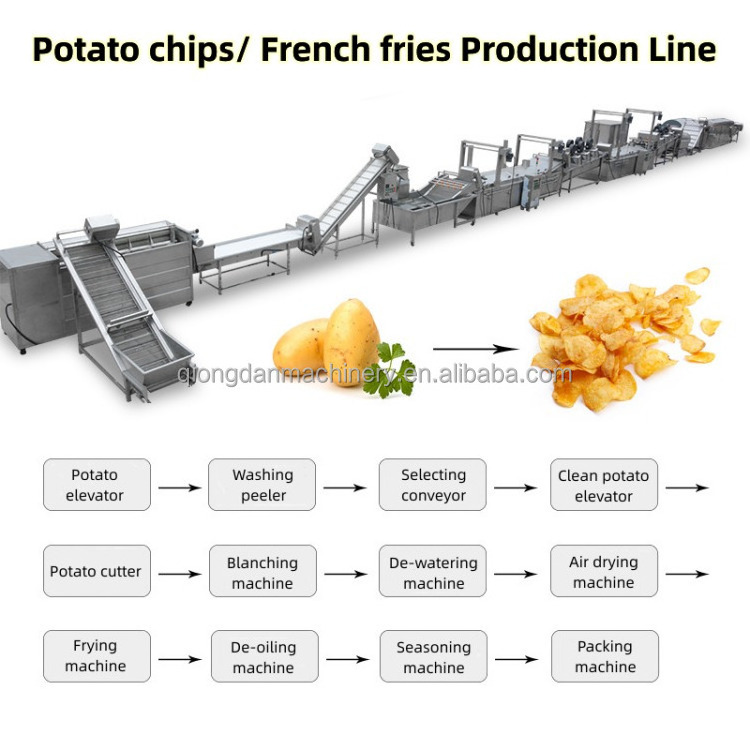

Description of potato chips making machine

This is a perfect fully automatic production line to produce good quality French fries and potato chips . We produce capacity of 20-1000kg/h of finished products. Our production line has become the most popular product both in domestic and abroad. It enjoys the advantages of high automation, simple operation and energy-saving.

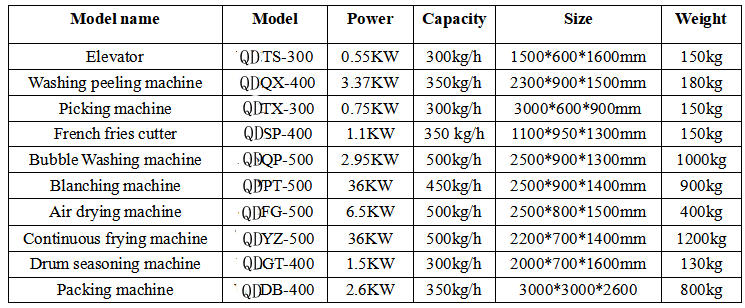

Parameter of potato chips and french fries making machine

1. Hoister:

It is used to lift fresh potatoes into next step screw washing and peeling machine automatically.

2. Washing and Peeling machine:

I

ntegrates the function of washing and peeling, and it can be used for processing potatoes, carrots, cassava and other root vegetables.

3. Potato Picking machine:

For picking out the bad potatoes and dealing with the dead angles, black holes etc

4. Potato cutting machine: U sed for cutting the potatoes into slices, strips or cubes and also suitable for other root vegetables, like carrots, cassava etc.

5. Bubble cleaning machine: It adopts the bubble surfing, brushing, spraying technology for maximize clean of the objects. It is an indispensable washing device for the fruit and vegetable or seafood processing, and suitable for all kinds of processing scale enterprise.

6. Potato blanching machine: U sed for blanching the slices, strips or cubes of potatoes or any root vegetables. The main purpose of blanching is to ensure the potato chips, potato crisps or French fries brightness and crispy

7. Air drying mahcine: This machine is suitable for dewatering and deoiling of sterilized high and low temperature meat products, vegetable products and other soft packaging products after sterilization, and also suitable for removing surface water after vegetable cleaning.

8. Potato frying machine: A dopts oil-water mixing technology, so the sediment can be cleaned easily. Besides, the service time of the oil is prolonged and the cost is cut largely by taking use of the oil-water mixing technology .

9. Rotary seasoning machine : U sed for seasoning the fried potato chips, potato crisps or French fries. Which flavor is needed totally depends on yourself.

10. Packing machine: I mproves the packing efficiency and saves a lot of time. As fried potato chips are fragile, the nitrogen is necessary to keep food fresh, tasty and without damage.

Details of frozen french fries production line

Pictures of fully automatic french fries production line

Semi automatic potato chips french fries line