- Product Details

- {{item.text}}

Quick Details

-

Internal filling:

-

Polyurethane foam

-

Size:

-

Support customization

-

Application:

-

Anchorage of ships

-

Color:

-

Various

-

MOQ:

-

1pcs

-

Warranty:

-

12 months

-

Certificate:

-

BV, CCS, DNV, LR, ABS

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Henger

-

Shell material:

-

Steel

-

Internal filling:

-

Polyurethane foam

-

Size:

-

Support customization

-

Application:

-

Anchorage of ships

-

Color:

-

Various

-

MOQ:

-

1pcs

-

Warranty:

-

12 months

-

Certificate:

-

BV, CCS, DNV, LR, ABS

Steel M ooring B uoy

1. Product Introduction

Steel mooring buoy, refer to sealed steel buoys for mooring ships set on the offshore .

Steel mooring buoy is available for anchorage of ships of different tonnage. It is quite convenient and flexible to operate as using mooring buoy in anchorage , goods lightering works, maintenance & repair of ships can be operated on the berth. Therefore, the mooring buoy is an important anchoring facility of the port.

2. Structure and Material

Steel mooring buoy is a drum made of steel plate. Inside is filled with closed cell PE foam. It can prevent water flowing in in case of any broken and eventually provents the buoy from sinking into water. There is a steel pipe through the drum body for anchor chains.

The coating of buoy can be marine painting or sprayed with SUPA, which is better than painting for anti-uv.

Mooring Buoys have different sizes, each of which has related buoyance for certain anchoring tonnage case.

3.Technical parameters

|

Type |

Buoyancy (without chain) (t) |

Diameter X Height (m) |

Suitable for Ship Tonnage(t) |

|

2.0 |

3 |

2.0×1.74 |

<2000 |

|

2.6 |

6 |

2.6×2.27 |

<5000 |

|

3.6 |

19 |

3.6×2.14 |

<10000 |

|

5.0 |

28.5 |

5.0×3.4 |

<12000 |

|

5.5 |

31.2 |

5.5×3.0 |

<100000 |

|

6.0 |

34.2 |

6.0×3.2 |

<150000 |

|

8.0 |

40.3 |

8.0×2.46 |

<250000 |

4. Use of mooring buoys

The anchor is buried in the offshore seabed, and the buoy is connected to the anchor by a mooring chain to float on the water and does not drift away with the waves or currents;

the buoy is equipped with mooring rings and steel shackles for ship mooring, some of which are large The mooring buoy is also equipped with manual quick decoupling to facilitate quick mooring and de-mooring operations.

In offshore mooring work, dedicated mooring boats are generally used to assist ships in mooring operations.

In the case of a single buoy mooring, the ship will drift around the buoy under the action of wind and current. For this reason, double buoys are often used for mooring in the port, that is, a buoy is attached to the bow and stern cables, and the ship can be stabilized on the water surface. For some large oil tankers, LNG uses four-point mooring, that is, two buoys are connected to the bow line and two buoys are connected to the stern line.

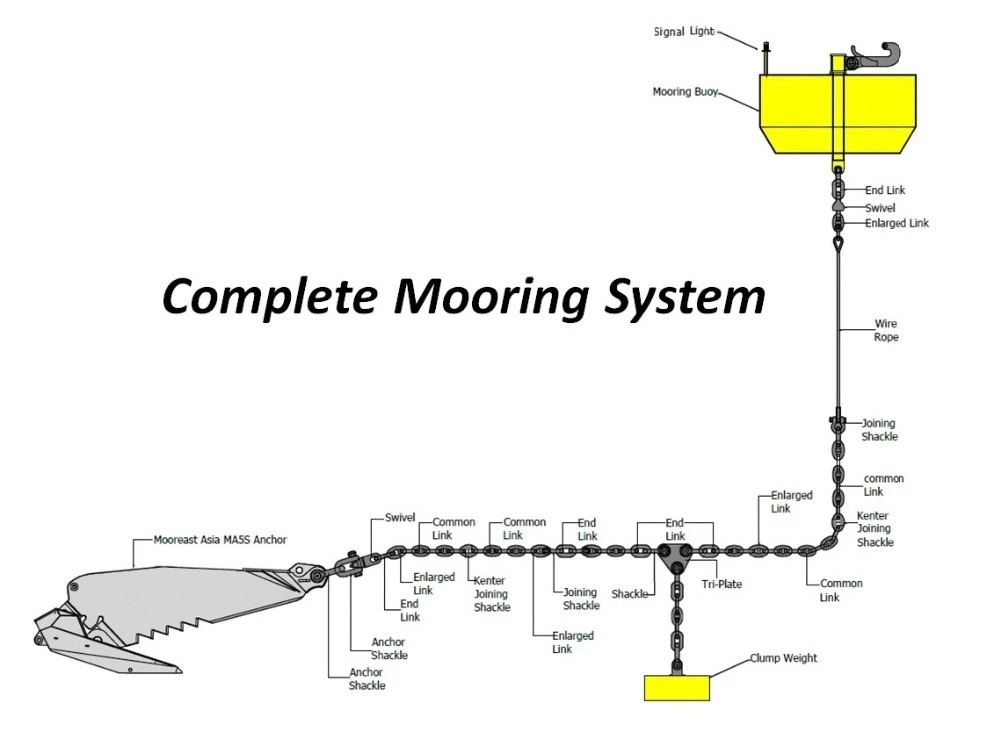

5. Complete mooring system

A complete mooring system main ly consists of three parts: steel buoys, mooring chains and anchorages.

6 . Features of steel buoy

1. The steel buoy is resistant to impact and wind and waves, has a compact and reasonable structure, simple installation, and excellent performance. As a floating material for water silt drainage pipelines, it has become a product of choice for today's silt transportation and drainage customers.

2. Good toughness, strong resistance to environmental stress cracking, suitable for offshore and lake construction.

3. High bearing capacity, light weight, strong wear resistance, easy installation and handling, low transportation and transfer cost, stable and durable cylinder.

4. Corrosion resistance, strong weather resistance, long life, anti-oxidation, anti-ultraviolet rays.

7 . C lassifications of steel buoy

According to the shape, it can be divided into horizontal cylinder type, drum type, gyro type, etc.

horizontal cylinder type

drum type

gyro type