- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

2000

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Video technical support

-

kind:

-

one-touch intelligent

-

MOQ:

-

1 piece

-

Gurantee:

-

1 year

-

Weight:

-

2000kgs

-

Certification:

-

CE ISO

Quick Details

-

Machine Type:

-

Coating Production Line, Spray Booths, Painting Equipment, Drying Oven, Curing oven, Coating Equipment, Other

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

COLO

-

Weight (KG):

-

2000

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Video technical support

-

kind:

-

one-touch intelligent

-

MOQ:

-

1 piece

-

Gurantee:

-

1 year

-

Weight:

-

2000kgs

-

Certification:

-

CE ISO

Product Description

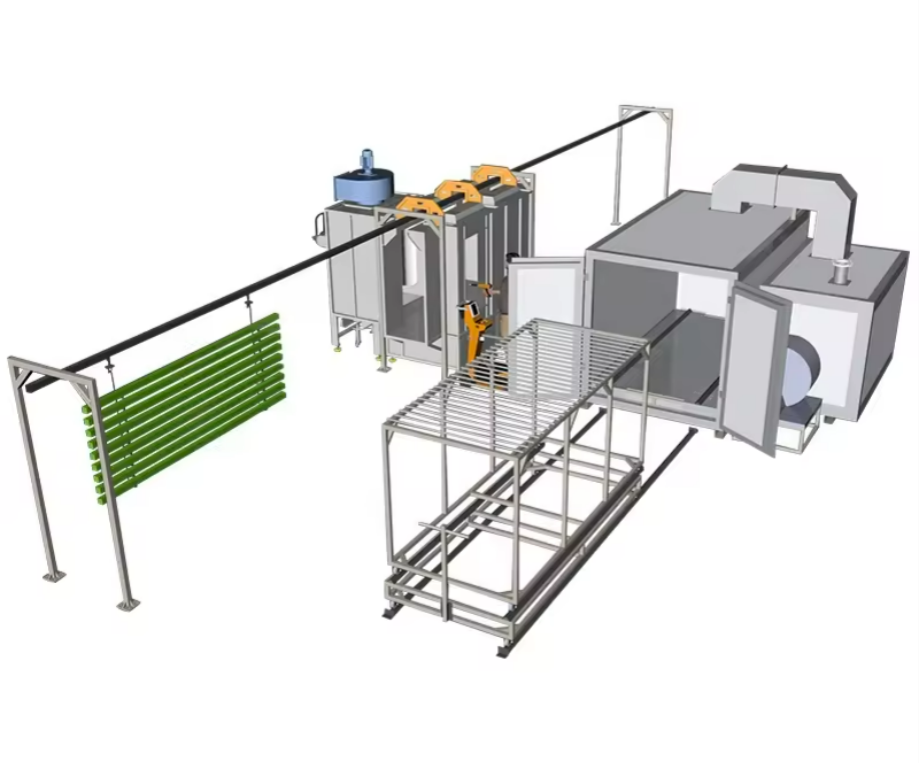

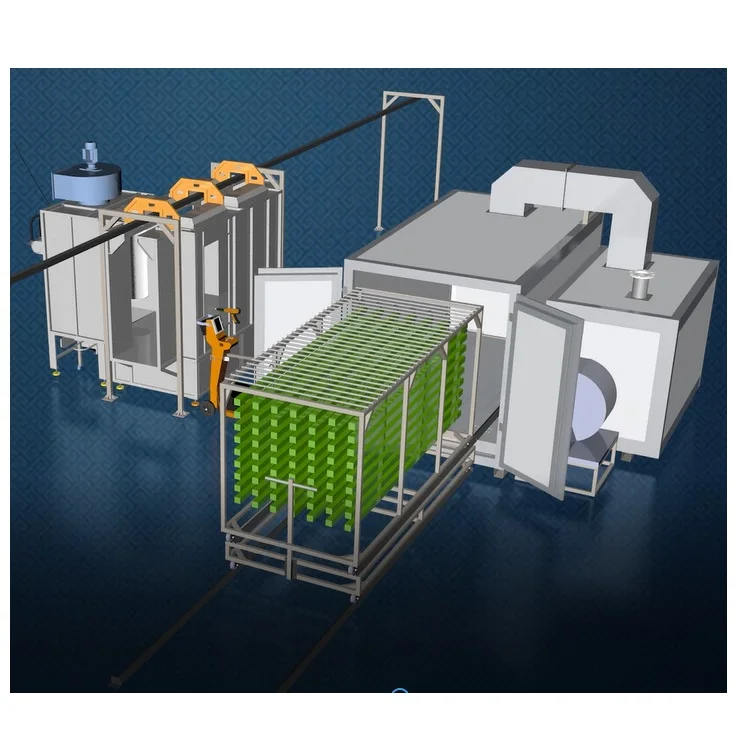

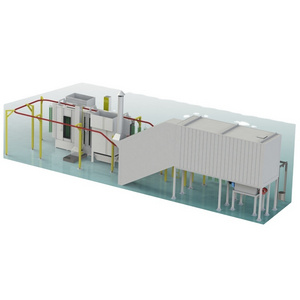

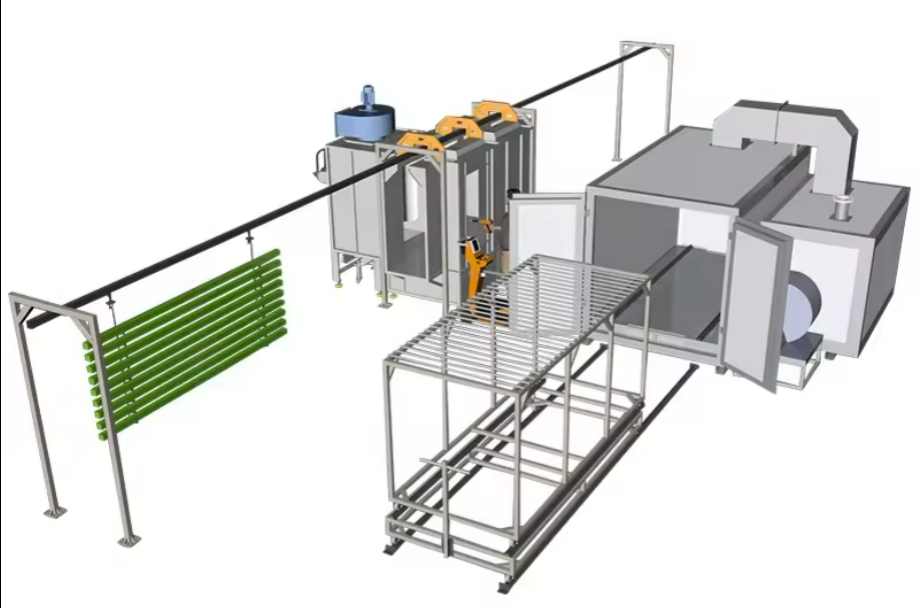

Aluminium profile manual powder coating line system powder spray machine package

This powder coating line system include powder spray gun, spray booth and curing oven for one whole set. This set is very suitable for the aluminum profile,

doors, handrails

powder coating.

This manual powder coating machine package gives an easy and quick start of powder coating businesses. Efficient and economical solution for powder coating batch rims, car parts, bike and bicycle accessories.

Details Images

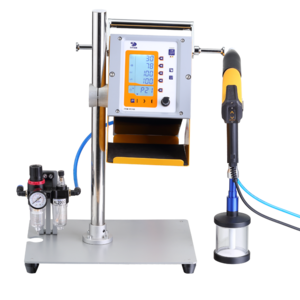

COLO-191S powder coating gun machine

1. This powder coating gun uses advanced digital valve controlled technology, delivering more uniform and smooth powder flow, which ensures perfect coating results.

2. The powerful control panel offers great experience for both beginners and specialists.

3. Three pre-set application programs stand for flat parts, profiles, re-coating.

4. 100kv manual spray guns delivers high transfer efficiency with long time working.

5. Allows users create and store 20 kinds of programs for individual jobs.

6. Box feed type, direct put the powder carton the the inclined table, suitable for muilti color application.

7. Compact design, easy to move and save space.

COLO-S-3212 Pass Thru Powder Coating Booth Features

1. The recovery module combines 6 pcs high-precision filters made of 100% polyester that maximize separating efficiency.

2. Pulse jet device provides interval filters cleaning, effectively eliminates powder accumulation and prolongs filters' useful life.

3. Full parameters and functions can be handled on the PLC panel, such turning on / off fan, setting pulse-jetting time and interval, light on/off, emergency stop etc.

5. The booth body is made of powder-coated steel plate constructed for rust resistance, durability and ease of cleaning.

6. A collection hopper beneath the filter stage ensure the collected overspray powders are clean, and can be easily taken away for recycling.

7. Simple installation - only electrical and air connections are required to start production.

2. Pulse jet device provides interval filters cleaning, effectively eliminates powder accumulation and prolongs filters' useful life.

3. Full parameters and functions can be handled on the PLC panel, such turning on / off fan, setting pulse-jetting time and interval, light on/off, emergency stop etc.

5. The booth body is made of powder-coated steel plate constructed for rust resistance, durability and ease of cleaning.

6. A collection hopper beneath the filter stage ensure the collected overspray powders are clean, and can be easily taken away for recycling.

7. Simple installation - only electrical and air connections are required to start production.

|

Model

|

COLO-S-3212

|

|

Operating Dimensions

|

Width620 * Depth2920 * Heght1500mm

|

|

Overall dimensions

|

Width1200 * Depth3000 * Heght2033mm

|

|

Weight

|

500kg

|

|

Power Supply

|

220V/380V, 3Phase, 50-60HZ

|

|

Fan Power

|

4kw

|

|

Filter Count

|

6 pcs, Quick-release Type

|

|

Filter Material

|

Polyester

|

|

Filter Cleaning

|

Pneumatic

|

COLO-1732 Powder Coating Oven Features

1. All parameters and functions are set on PLC panel, provides a high precision heating process.

2. 100mm thick rockwool insulation material keeps constant temperature whose stability less than 3℃.

3. A high peformance fan is excellent for hot airflow circulation, reaching any corner of the oven to ensure baking uniformity and efficiency.

4. A pair of outer & inner trolley makes easy loading of workparts. It affects the reduction of the impurities content from the floor in the chamber.

2. 100mm thick rockwool insulation material keeps constant temperature whose stability less than 3℃.

3. A high peformance fan is excellent for hot airflow circulation, reaching any corner of the oven to ensure baking uniformity and efficiency.

4. A pair of outer & inner trolley makes easy loading of workparts. It affects the reduction of the impurities content from the floor in the chamber.

Related Products

Customer Feedback

Product packaging

Standard and Safety Export Packages

Inside with environment-friendly soft bubble paper , EPE foam wrapped well, carton outside for the delivery.

Inside with environment-friendly soft bubble paper , EPE foam wrapped well, carton outside for the delivery.

Hot Searches