- Product Details

- {{item.text}}

Quick Details

-

Ice storage capacity:

-

Other

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Linsky

-

Dimension(L*W*H):

-

5056mm*2390mm*3577mm

-

Weight:

-

26 KG

-

Product name:

-

Equipment Block Ice Plant Project 100 Tons Ice Block Machine

-

Cooling way:

-

Water-cooled

-

Compressor:

-

Bitzer/Hanbell

-

Refrigerant:

-

R404a/R22/R507

-

Daily capacity:

-

100Ton/24hr

-

Power supply:

-

380v/3p/50hz

-

Control system:

-

PLC+Push Button

-

Expansion valve:

-

Denmark Brand Danfoss

-

Material:

-

Aluminum

-

Ice Weight:

-

50kg/100kg/15kg/200kg

Quick Details

-

Ice Shape:

-

ICE BLOCK

-

Voltage:

-

380V/50HZ/3P

-

Power:

-

360kw

-

Ice storage capacity:

-

Other

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Linsky

-

Dimension(L*W*H):

-

5056mm*2390mm*3577mm

-

Weight:

-

26 KG

-

Product name:

-

Equipment Block Ice Plant Project 100 Tons Ice Block Machine

-

Cooling way:

-

Water-cooled

-

Compressor:

-

Bitzer/Hanbell

-

Refrigerant:

-

R404a/R22/R507

-

Daily capacity:

-

100Ton/24hr

-

Power supply:

-

380v/3p/50hz

-

Control system:

-

PLC+Push Button

-

Expansion valve:

-

Denmark Brand Danfoss

-

Material:

-

Aluminum

-

Ice Weight:

-

50kg/100kg/15kg/200kg

Ice plant system Description

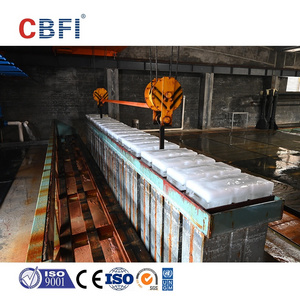

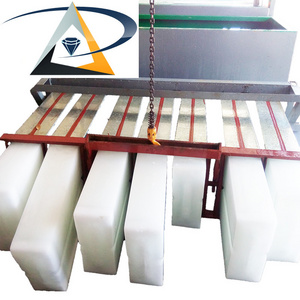

Equipment Block Ice Plant Project 100 Tons Ice Block Industrial Factory Machine

Brine cooling block ice plant handles all activities including the production, storage, transportation, wholesale and retail of block ice. The capability of a typical brine system block ice plant can be planned as much as 10~500ton/day but shall be based on the surrounding environment and the actual demand. Larger-scale ice production factory also can be designed as per client's requirement.

|

Equipment Block Ice Plant Project 100 Tons Ice Block Industrial Factory Machine

|

|

The advantages of brine cooling block ice plant:

|

|

* Simple refrigeration system, yet stable and reliable to run; low investment and low maintenance cost;

|

|

* Large dimension ice block can be crushed into various shapes of ice as per clients requirement;

|

|

* Large dimension ice block has less weight deviation, very convenient for ice transportation, storage and measurement;

|

|

* Ice block can be put into mass production;

|

|

* Fast return on investment like that 1~2 years can pay for itself

|

Target customers of brine cooling block ice plant

* Ice in supermarket/grocery market:

Mainly used for low temperature preservation and display of seafood, meat and vegetable in market;

* Ice in seafood preservation:

All fresh seafood need to be preserved in low temperature to keep them fresh at around +3~+6°C, so a lot of crushed block ice is in great need.

* Ice in fishing vessels:

Fishing vessels usually go out for fishing after charging full ice at dock. Seafood must be covered with ice immediately after catching to ensure its freshness.

* Ice in transport of vegetable:

Still grows after vegetable picked down, it will release a lot of respiratory heat. During its transportation process, vegetable will be stacked by one layer of ice and one layer of veggie to ensure its quality.

* Ice in aqua farm:

Fish fond temperature control for aquatic product culture like sea cucumber, will need a great deal of ice

* Ice in environment cooling:

In high temperature days, to ensure normal work such as in workshop, classroom, aisle and mine, ice is stacked to lower down environment temperature;

*

Ice in sculpture:

Linsky aluminum direct block ice plant can produce crystal, milky color or semi-transparent ice for different engraving use

Factors when you considering brine cooling block ice plant

* Considering transportation cost, the optimum ice distribution distance is suggested within 30km. It would better to build an ice plant near your customer group;

* Brine system block ice plant needs relative large capacitance. Equipped with capacitance of 4KVA per tonnage, and it is suggested to choose the location with time-of-use electricity price;

* Brine system block ice plant should have sufficient and clean water supply. Try not use groundwater, especially for cooling tower because it will make serious scales in condenser. Scaling will lead to excess high pressure for the refrigeration system and will consume more energy;

* Location try not to approach residential area because compressor, cooling tower and ice hoisting device could probably cause noise pollution;

* Need to contact with your contractor about ice plant land use, especially for the second even third stage plan;

* Know our local time-of-use electricity price, local labor cost to confirm your ice production cost and price of ice, evaluate your investment on return.

* Brine system block ice plant needs relative large capacitance. Equipped with capacitance of 4KVA per tonnage, and it is suggested to choose the location with time-of-use electricity price;

* Brine system block ice plant should have sufficient and clean water supply. Try not use groundwater, especially for cooling tower because it will make serious scales in condenser. Scaling will lead to excess high pressure for the refrigeration system and will consume more energy;

* Location try not to approach residential area because compressor, cooling tower and ice hoisting device could probably cause noise pollution;

* Need to contact with your contractor about ice plant land use, especially for the second even third stage plan;

* Know our local time-of-use electricity price, local labor cost to confirm your ice production cost and price of ice, evaluate your investment on return.

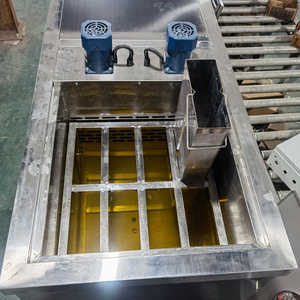

Solutions to a typical brine system block ice plant

A: Brine system block ice machine A1: Cooling tower

A2: Air-cooled condenser

A3: Evaporative condenser

B: Block ice lifting conveyor

C: Block ice sliding chute

D: Ice storage

D1: Refrigeration unit of ice storage

E: Block ice lifting conveyor

F: Block ice crusher

G1: Crawler conveyor

G2: Screw conveyor

A2: Air-cooled condenser

A3: Evaporative condenser

B: Block ice lifting conveyor

C: Block ice sliding chute

D: Ice storage

D1: Refrigeration unit of ice storage

E: Block ice lifting conveyor

F: Block ice crusher

G1: Crawler conveyor

G2: Screw conveyor

Brine system block ice machine A can adopt three cooling methods, respectively are cooling tower system A1, air-cooled condenser A2, evaporative-cooled condenser A3. Ice blocks forms and then will be lifted by B lifting conveyor to a certain height. Ice could slide from C ice chute to the inside of ice storage D. the refrigeration unit D1 keeps cold room temperature at around -8°C so the ice will not melt. When need to use ice block, customer can rely on another block ice lifting conveyor E to deliver ice to the truck. When crushed ice block is in need, customer can start ice crusher F. the crushed ice will be transported through crawler conveyor G1 or screw conveyor G2 to the truck.

Linsky could tailor made brine system block ice plant solutions and investment feasibility proposal according to clients land,capacity and local weather conditions.

Linsky could tailor made brine system block ice plant solutions and investment feasibility proposal according to clients land,capacity and local weather conditions.

Linsky Ice Machine Factory Introduction

Shanghai Snowdream Refrigeration Equipment Co., Ltd, as the leading manufacturer and exporter of commercial and industrial ice machines in China, with a decade of professional experience in ice cooling field, has been approved with CE and ISO9001-2000.Brand is "Linsky".

Linsky's products lineup include high quality tube ice machine, aluminum direct system block ice machine, brine system ice block machine, flake ice machine, plate ice machine, cube ice machine, water chiller, cold room units and other associated equipments,such as rake type automatic ice storage, screw type automatic ice storage, pneumatic ice delivery system, screw ice delivery system, ice crusher, ice weighing system, ice packaging machine and more.

We don't just make ice machines. We also help customer design ice cooling solutions. The main feature of Linsky product is tailored specifically to the demands of the customer. Above all else, this includes energy efficient, longevity and hassle-free.

Linsky's products lineup include high quality tube ice machine, aluminum direct system block ice machine, brine system ice block machine, flake ice machine, plate ice machine, cube ice machine, water chiller, cold room units and other associated equipments,such as rake type automatic ice storage, screw type automatic ice storage, pneumatic ice delivery system, screw ice delivery system, ice crusher, ice weighing system, ice packaging machine and more.

We don't just make ice machines. We also help customer design ice cooling solutions. The main feature of Linsky product is tailored specifically to the demands of the customer. Above all else, this includes energy efficient, longevity and hassle-free.

FAQ

If you need whole ice plant exact quote, please reply us following questions:

1.How many ton of flake ice do you need per 24hours? We have 20Ton, 30Ton up to 100Ton.

2.How many ton ice storage do you need?

3.Do you need water chiller? how many ton per hour? What is the water inlet temperature and outlet temperature?

4.How many kg of weighing hopper do you need, 100kg, 200kg, 250kg, 300kg up to 1000kg?

5.How many meter of screw delivery system do you need? We have 5m up to 20m.

6.Do you need steel structure, ladder and rails or not?

7.Please provide the batching plant CAD drawing so that we can design the ice plant location, steel support height, screw delivery length and obliquity accurately.

8.Refrigerant, R22 or R404A?

9.Power supply, 380V 50HZ 3P, 380V 60HZ 3P, or others?

10.what is the water temperature and ambient temperature?

11.what your water inlet temperature?and what out temperature do you need?After this containerized water chiller plant can turn a 46 °C cooling water temperature to 1 °C.

1.How many ton of flake ice do you need per 24hours? We have 20Ton, 30Ton up to 100Ton.

2.How many ton ice storage do you need?

3.Do you need water chiller? how many ton per hour? What is the water inlet temperature and outlet temperature?

4.How many kg of weighing hopper do you need, 100kg, 200kg, 250kg, 300kg up to 1000kg?

5.How many meter of screw delivery system do you need? We have 5m up to 20m.

6.Do you need steel structure, ladder and rails or not?

7.Please provide the batching plant CAD drawing so that we can design the ice plant location, steel support height, screw delivery length and obliquity accurately.

8.Refrigerant, R22 or R404A?

9.Power supply, 380V 50HZ 3P, 380V 60HZ 3P, or others?

10.what is the water temperature and ambient temperature?

11.what your water inlet temperature?and what out temperature do you need?After this containerized water chiller plant can turn a 46 °C cooling water temperature to 1 °C.

Recommend Products

1.Linsky Industrial ice machine:

(1)Block ice machine: From 1Ton/24h to 30Ton/24h

(2)Tube ice machine: From 1Ton/24h to 30Ton/24h

(3)Cube ice machine: From 1Ton/24h to 20Ton/24h

(4)Flake ice machine: From 0.3Ton/24h to 30Ton/24h

(5)Plate ice machine: From 1Ton/24h to 40Ton/24h

(6)Bag ice machine: From 1Ton/24h to 30Ton/24h

2.Linsky Commerial ice machine:

(1)Cube ice machine: From 50kg/24h to 1000kg/24h

(2)Snow ice machine: From 100kg/24h to 500kg/24h

(3)Crescent ice machine: From 210kg/24h to 270kg/24h

3.Linsky Refrigeration compressor unit:

(1)Bitzer compressor unit

(2)Hanbell compressor unit

4.Linsky Others:

(1)Ice crusher

(2)Ice packing machine

(3)Water chiller

(4)Ice storage

(5)Ice screw conveyor

(2)Tube ice machine: From 1Ton/24h to 30Ton/24h

(3)Cube ice machine: From 1Ton/24h to 20Ton/24h

(4)Flake ice machine: From 0.3Ton/24h to 30Ton/24h

(5)Plate ice machine: From 1Ton/24h to 40Ton/24h

(6)Bag ice machine: From 1Ton/24h to 30Ton/24h

2.Linsky Commerial ice machine:

(1)Cube ice machine: From 50kg/24h to 1000kg/24h

(2)Snow ice machine: From 100kg/24h to 500kg/24h

(3)Crescent ice machine: From 210kg/24h to 270kg/24h

3.Linsky Refrigeration compressor unit:

(1)Bitzer compressor unit

(2)Hanbell compressor unit

4.Linsky Others:

(1)Ice crusher

(2)Ice packing machine

(3)Water chiller

(4)Ice storage

(5)Ice screw conveyor

Dear friends, don't hesitate to send your inquiry if you are interested!

We would be very glad to be in service for you, as professional ice machine manufacturer in China, we are pleased to attach our best offer. We are definitely to contact you within 12 hours after getting your inquiry.

Yuna

We would be very glad to be in service for you, as professional ice machine manufacturer in China, we are pleased to attach our best offer. We are definitely to contact you within 12 hours after getting your inquiry.

Yuna

whatsapp: +86 13156526006

email: yuna.zhang@linskyice.com

wechat: +86 13156526006

email: yuna.zhang@linskyice.com

wechat: +86 13156526006

Hot Searches