- Product Details

- {{item.text}}

Quick Details

-

solid content:

-

40%

-

main material:

-

acrylic emulsion

-

PH:

-

7

-

Ionic type:

-

anion

-

Application:

-

fabric

Quick Details

-

CAS No.:

-

61788-97-4

-

Place of Origin:

-

Shandong, China

-

color:

-

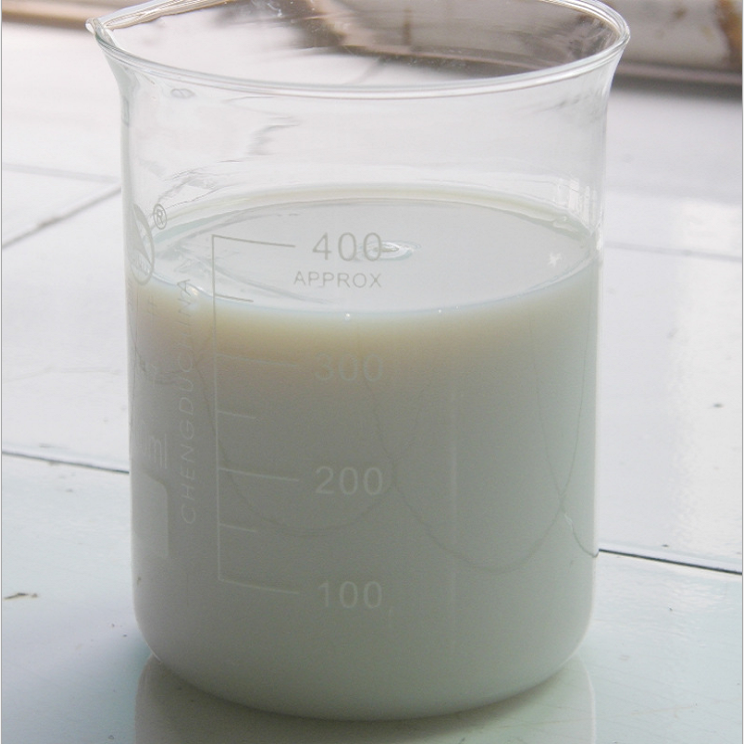

white

-

solid content:

-

40%

-

main material:

-

acrylic emulsion

-

PH:

-

7

-

Ionic type:

-

anion

-

Application:

-

fabric

Fabric stiffening finishing agent is polymerized emulsion of acrylic acid and other polymer materials. It is suitable for hard finishing of all kinds of fibers.

Y405

is a stable, easy to use polyester emulsion for fabric and non fabric finishing. It can make all kinds of woven fabric or knitwear, non fabric with excellent hardened feeling and lower scraper at the same time; it has excellent adhesion to most materials, excellent alcohol resistance and water resistance. Its resin has higher gloss and transparency, and is environmentally friendly. It does not contain formaldehyde, APEO, 6P, heavy metals, etc.

Application information

After dilution to the required solid content, Y405 is used by impregnation or spraying.

Thermosetting / drying: drying / thermosetting time and temperature depend on the type of drying and thermosetting machine used. Suggested thermosetting conditions: 140-150 centigrade (2-5 minutes)

Typical characteristics

(1) polymer type... Polyester emulsion

(2) glass conversion temperature... 50-52 degrees centigrade

(3) the content of solid... 40%

(4) Brookfield viscometer (25 degrees Celsius,... Less than 100CPS)

(5) pH (25 degrees C)... 4 - 5

(6) ionized... Anionic type

Mechanical stability

Y405 has good mechanical stability and excellent mechanical properties. It can be shared with other vinyl acetate or acrylic emulsion.

Storage conditions

Products should be stored in closed containers to avoid freezing and high temperature. In the case of possible, it should be three months

Internal use. It is suggested that the normal storage temperature is at 10-35.