- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

CV01

-

Brand Name:

-

FL

-

Product name:

-

spring loaded check valve basement floor drain dual plate check valve

-

Standard:

-

DIN3356 API594

-

Connection:

-

wafer type

-

Size:

-

DN40-600

-

Pressure:

-

PN10/PN16

-

Working Temperature:

-

10-120℃

-

Medium:

-

Water

-

Body material:

-

Ductile Iron GG25/GGG50

-

Seal Material:

-

NBR EPDM

Quick Details

-

Port Size:

-

DN40-DN600

-

Warranty:

-

18 months

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

CV01

-

Brand Name:

-

FL

-

Product name:

-

spring loaded check valve basement floor drain dual plate check valve

-

Standard:

-

DIN3356 API594

-

Connection:

-

wafer type

-

Size:

-

DN40-600

-

Pressure:

-

PN10/PN16

-

Working Temperature:

-

10-120℃

-

Medium:

-

Water

-

Body material:

-

Ductile Iron GG25/GGG50

-

Seal Material:

-

NBR EPDM

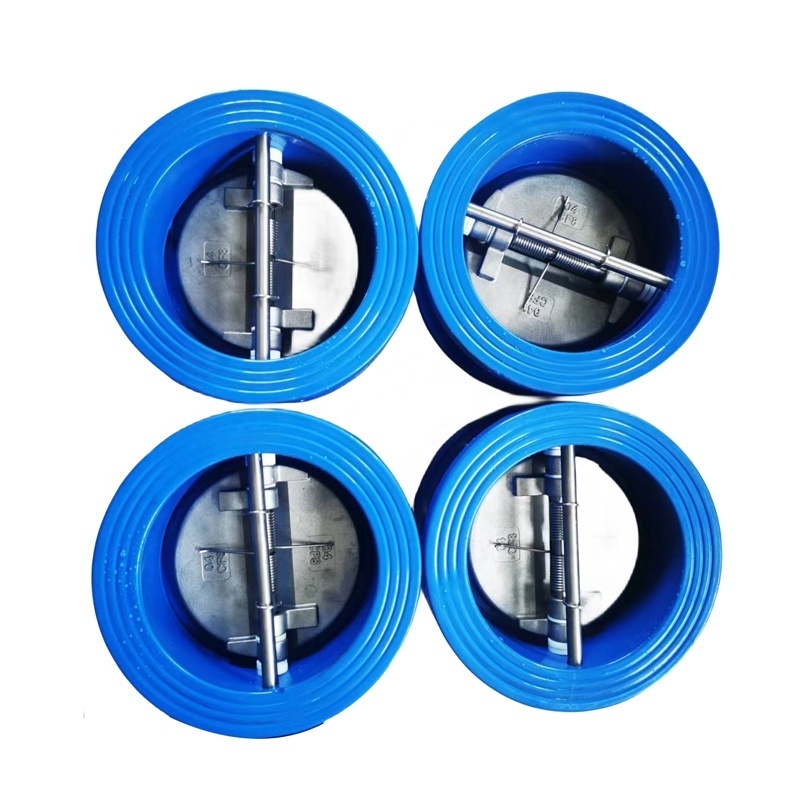

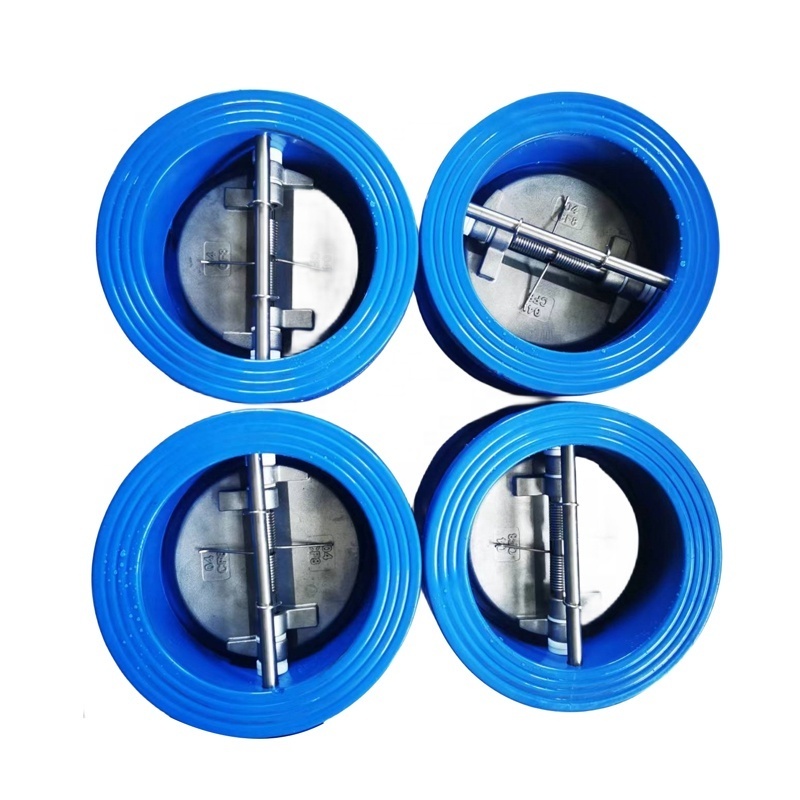

Features:

Wafer type

Dual plate disc

Vulcanized rubber seat

Surface treatment:RAL5017 FBE Coated

Technical Specification:

Design:DIN3356;API594

Face to face:DIN3302;ANSI B16.10

Hydraulic test:API598

Seat Test: 17.6bar

Shell Test: 24bar

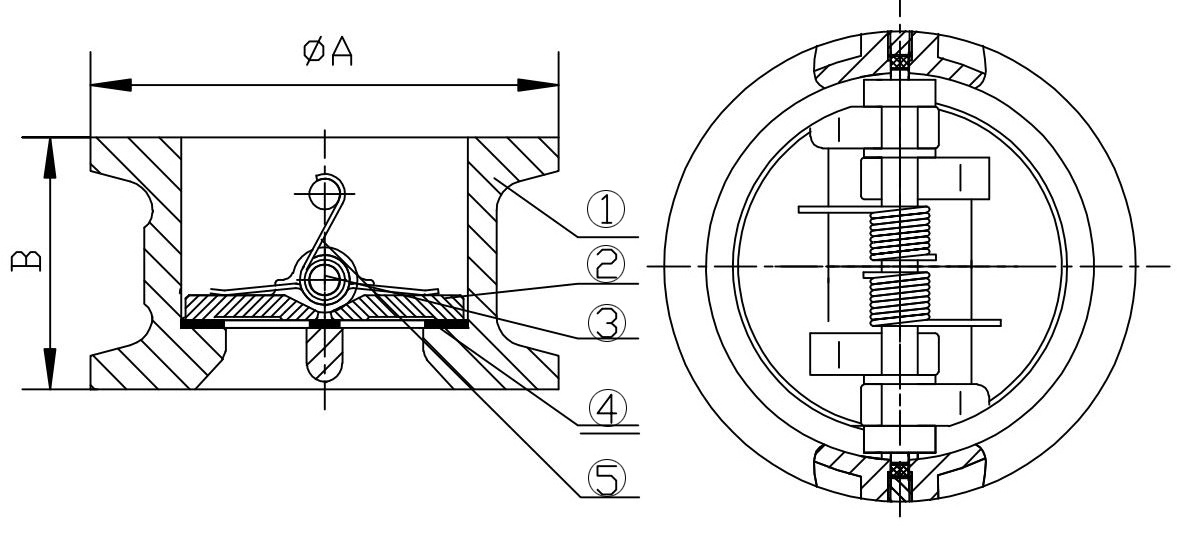

|

Item No.

|

Part Name

|

Specification

|

|

1

|

Body

|

Ductile Iron GGG50

|

|

2

|

Disc

|

DI, SS304,SS316,C95400

|

|

3

|

Seat

|

EPDM BUNA

|

|

4

|

Stem

|

SS410 SS420

|

|

5

|

Spring

|

SS316

|

1.Q: Can I have your drawing?

A: Yes, assembly drawings can be submitted for approval prior to manufacturing and approved by the buyer. All Lettering is to be mentioned on the drawing, it can be in both CAD and PDF version.

2.Q: Can you provide OEM service?

A: Yes, all products could carry your own Logo (As Cast) and Heat No, lettering sizing to be as per your request.

3.Q:What's the surface treatment?

A:Fusion Bonded Painting, also call epoxy painting,Painting Thickness of above 200 microns is to be maintained internally & externally on cast bodies. WRAS approved Powder is available, please mention it before ordering if needed.

4.Q:What's the quality request of castings?

A:All Castings should be free from all kinds of manufacturing defects, grinding marks, poor lettering, and coating finish.

5.Q:Will you do pressure testing for each of the valve before shipment?

A: Yes,All VALVES must be hydro-tested for Body Leak Test 1.5 times of nominal pressure, and Seat Leak Test 1.1 time of nominal pressure.Take PN16 valve for example, Body Leak Test(24 Bar),while Seal Test(17.6 Bar).

5.Q: What about the operation or actuators for the valves?

A:All Hand-wheels should be placed along with Valve bodies for DN50-DN600. DN700-DN1200 can be completed with bevel gear box with indicators or electric actuators.

6.Q: Is the body lettering clear enough?

A:Body letterings should be clearly visible and free from excess paint deposition

7. Q: How's the valve to be packed?

A: Valves must be bubble-wrapped prior to box packaging. Sufficient Packaging to be used to avoid any coating damages. The box frame should be strong enough to handle valve weights.

Export Quality Plywood Packaging with adequate leg space for the forklift entry from both sides. Leg Space is to be provided for Forklift Entry.

8. Q: How long is the warranty?

A: 18 months, Manufacturer to provide 18 months Warranty Certificate for supplied materials.

Hot Searches