- Product Details

- {{item.text}}

Quick Details

-

Rated Input Voltage:

-

380 V

-

Rated Output Current (MIG):

-

500A

-

Rated Output Voltage (MIG):

-

39 V

-

Welding Current/Voltage Range:

-

40-500A

-

Wire Feeding Speed:

-

0.8 m/min

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Panasonic

-

Dimensions:

-

76.2*38*61.2cm

-

Use:

-

CO2, MAG, MIG

-

Weight (KG):

-

60 KG

Quick Details

-

Wire Melting Type:

-

Short Circuit Transfer

-

Max. Load Power Capacity:

-

23.3KVA

-

Rated Duty Cycle @40°C (MIG):

-

100%

-

Rated Input Voltage:

-

380 V

-

Rated Output Current (MIG):

-

500A

-

Rated Output Voltage (MIG):

-

39 V

-

Welding Current/Voltage Range:

-

40-500A

-

Wire Feeding Speed:

-

0.8 m/min

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Panasonic

-

Dimensions:

-

76.2*38*61.2cm

-

Use:

-

CO2, MAG, MIG

-

Weight (KG):

-

60 KG

Digital IGBT Control MIG/MAG welding machine 350/500FR2

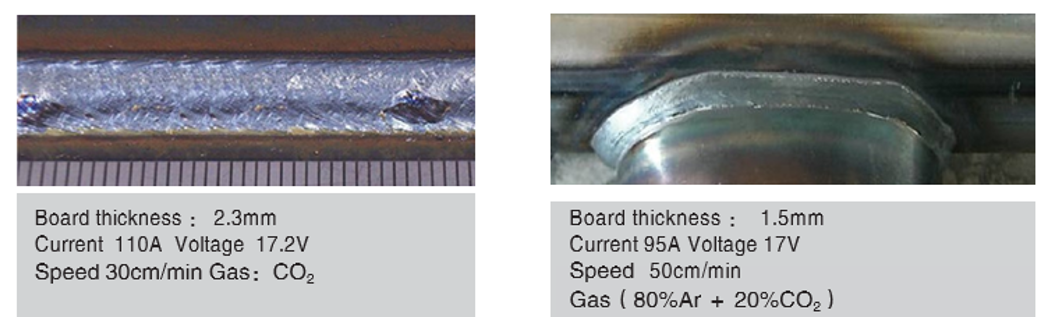

1. Standard mode

This mode is suitable for general welding needs. In this mode, various welding parameters can be set freely and finely according to the welding process and operating habits; the unified adjustment method is adopted, and the welding voltage is automatically matched when the current is adjusted.

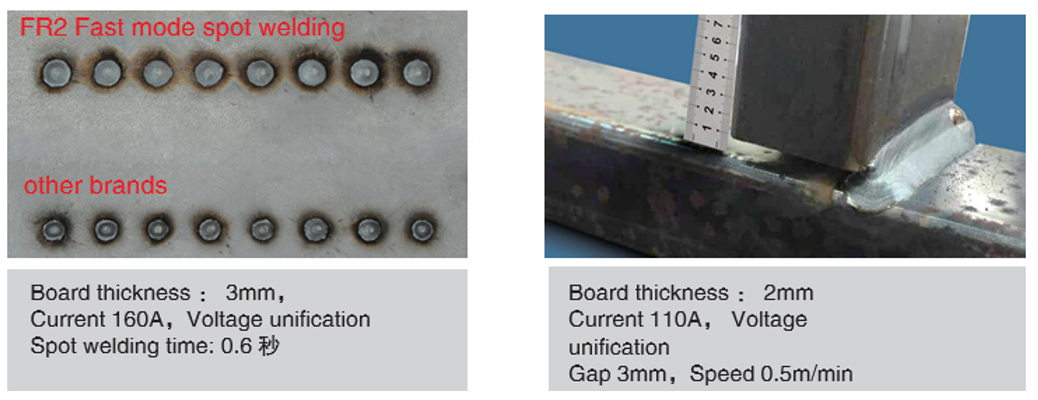

2. Fast mode

Welding expert mode customized for fast spot welding and short seam fast welding. This mode is characterized by fast arc ignition and fast welding. The switch is welded when pressed, and stopped when released, with high welding cycle and high work efficiency.

3.Welding rod mode

3.1 You can switch to the "manual welding electrode" mode through the detailed menu, and the electrode with a diameter of up to 5.0 can be used, which is suitable for all kinds of acid-base electrodes.

3.2 This mode is suitable for long-distance welding operations, maintenance and other occasions.

3.3 It has the functions of thrust current adjustment and arc ignition current adjustment.

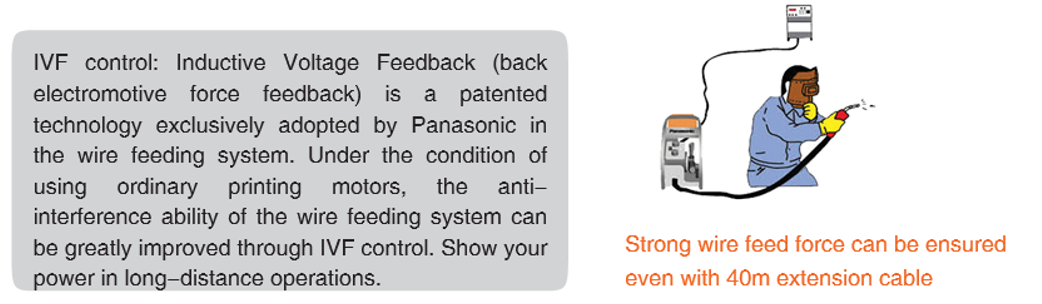

4.High-performance wire feeding system

The wire feeding control system adopts IVF patented technology, with strong wire feeding force and good welding stability. Even in the case of a 40-meter extension cable, it can still ensure normal wire feeding force.

5. Digital panel, simple function parameter setting

5.1 High-brightness, seven-segment digital display, which can display preset current and voltage, actual welding current and voltage, fault code, wire feeding speed and time.

5.2 The use of light touch buttons makes parameter setting convenient.

|

Power supply model |

YD-350FR2 |

YD-500FR2 |

|

|

Product Serial Number |

YD-350FR2HGE |

YD-500FR2 HGE |

|

|

Control method |

Digital IGBT control |

||

|

Input voltage |

AC 3*380V 50/60 Hz |

||

|

Rated input capacity |

13.5kVA |

23.3kVA |

|

|

Rated input power |

13 kW |

22.4kW |

|

|

Rated output current |

DC 350 A |

DC 500 A |

|

|

Rated output voltage |

31.5 V |

39 V |

|

|

No-load voltage |

DC 70 V |

DC 70 V |

|

|

Output current range |

DC 40~430 A |

DC 60~550 A |

|

|

Output voltage range |

16~35.5 V |

17~41.5 V |

|

|

Rated load duration |

60% |

100% |

|

|

Normative adjustment |

Separate/unary |

||

|

Welding method |

CO2/MAG/Stainless Steel MIG |

||

|

Cooling method |

Forced air cooling |

||

|

Applicable wire type |

Drug core / solid core |

||

|

Protection level |

IP23S |

||

|

Suitable for welding wire |

Solid core 0.8/1.0/1.2mm |

Solid core 1.0/1.2/1.6mm |

|

|

Drug core 1.0/1.2mm |

Drug core 1.2/1.4/1.6mm |

||

|

Protective gas |

CO2:100% MAG Ar:80%,CO2:20% MIG Ar:98%,O2:2% |

||

|

Advance air supply time |

0.2s |

||

|

Lag out time |

0.5s |

||

|

Spot welding time |

|

||

|

Dimensions (lL× W × H) |

372×575×632 mm |

372×575×632 mm |

|

|

Weight |

54 kg |

60 kg |

|

* Long-term stock

* Focus on welding and cutting equipment

* View our Factory.

Y.Are you manufacture or trade company ?

M:We are professional manufacturer of many kinds welding and cutting machine.

Y:How to package?

M:Frist layer, covered by plastic film for waterproof,second layer:covered by foam to protect the machine from shaking ,third layer:steel craft case or wooden cases.

Y:Will the package strong enough?

M:Our package is strong enough,nearly all our machine is packed in this way,and the customers receive in good state,So please don't worry,you will receive the welding machine in good condition.,but also can package as your requirement.

Y:How can you guarantee the quality of welding machine?

M: we have passed the ISO test,and if you have time,you can come to our factory to check the machine before order .and we have one year guaranteed,free parts can be send free within one year.

Y:How to install and operate the machine?

M:1.the machine is installed by us before send out,you need to install some parts according to the vedio and manual we send to you.

2.engineer can come to your side to install for you if need

3.install and operate training can be offer in our factory or in your side.

Y:What can I to do if the machine have problem?

M:please contact us at the frist time,and don't repair in your side,we will tell you how to solve it after discuss,we can guaranteed to solve within 24h if not the part break.

Y:how is your after-sale customer service?

M:you can contact our sales manager if have any question,we are online everyday.

Y.How to place an order?

M:1). Tell us the welding material ,welding size ,welding thickness...etc ,the more detailed the better .

2). After view your requirement ,we offer best plan and quotation .

3). Price confirmed ,we can proceed order and arrange shipment to your country.