(1)High porosity, high flux;

(2)Good chemical resistance, tolerating basic,acid, organic solvents and oxidant;

(3)High heat resistant ;

(4)High hardness, goodwear resistance, long service life;

(5)

Low operating pressure,

low energy consumption;

(8)Low footprint, membrane replaceable, easy installation and maintenance;

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

37.5 kg

-

Membrane material:

-

Silicon Carbide

-

Membrane area:

-

15.7㎡

-

Average pore size:

-

0.1-0.4μm

-

Pure water flux:

-

1000-1600L/㎡/h

-

Ph:

-

0~14

-

Maximum vacuum pressure:

-

-700mbae

-

Maxmium backwash pressure:

-

3bar

-

Operating temperature:

-

5-80℃

-

Apical cap material:

-

PPS/GPA

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SiFLUX

-

Material:

-

FRP/UPVC/ss

-

Weight (KG):

-

37.5 kg

-

Membrane material:

-

Silicon Carbide

-

Membrane area:

-

15.7㎡

-

Average pore size:

-

0.1-0.4μm

-

Pure water flux:

-

1000-1600L/㎡/h

-

Ph:

-

0~14

-

Maximum vacuum pressure:

-

-700mbae

-

Maxmium backwash pressure:

-

3bar

-

Operating temperature:

-

5-80℃

-

Apical cap material:

-

PPS/GPA

Product Description

Silicon carbide (SiC), known as carborundum, is a synthetic ceramic material. It can be manufactured by silica and carbon at the temperature more than 2000℃. It is a good engineering ceramic, which shows many distinctive properties, highest hydrophilic, excellent acid and basic resistance, high chemical resistance, and high temperature resistance. Based on all those properties, SiC has been used to manufacture different membrane, including flat sheet, tubular and muti-tubular membrane, which has been successfully applied to waste water treatment in Oil & Gas,chemical, metallurgical, textile, medicine and food.

|

Plate size

|

L500*W160*H6

|

|

Membrane area

|

0.16㎡

|

|

Pore size

|

0.1-0.4μm

|

|

Module area

|

8㎡

|

|

No. of single ceramic plates

|

50

|

|

Pure water flux

|

12m³/h

|

Features of SiC Flat Sheet Membrane

-

Applications

-

SiC flat sheet membrane are widely used in petroleum, chemcial, metallurgical, coal, food, pharmaceutical, printing and dyeing and environmental protection industries.

Detailed Images

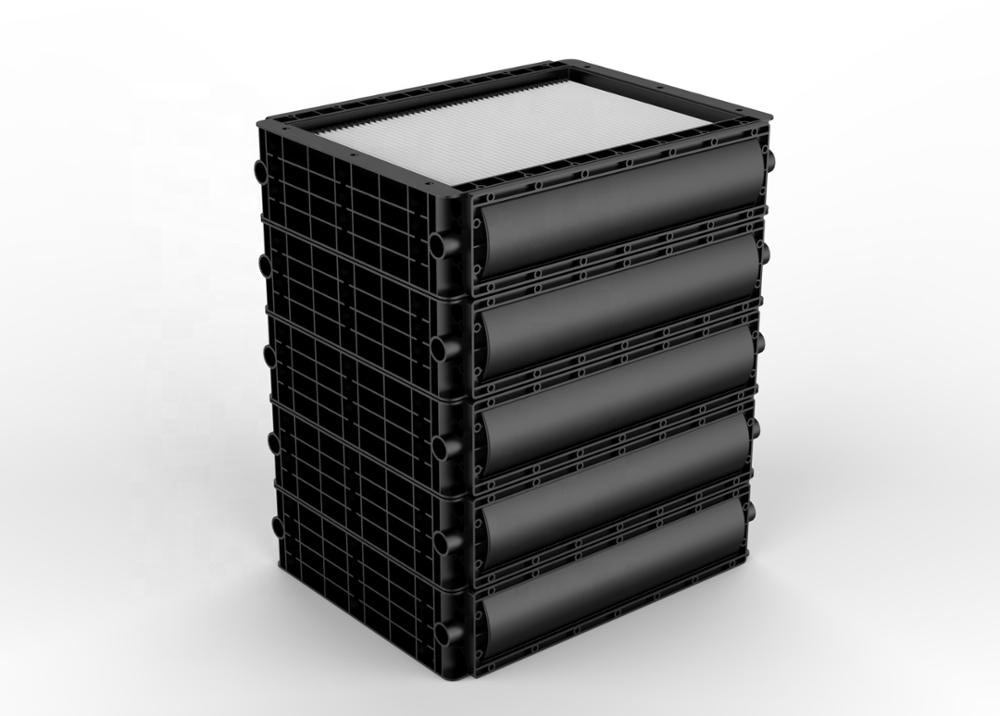

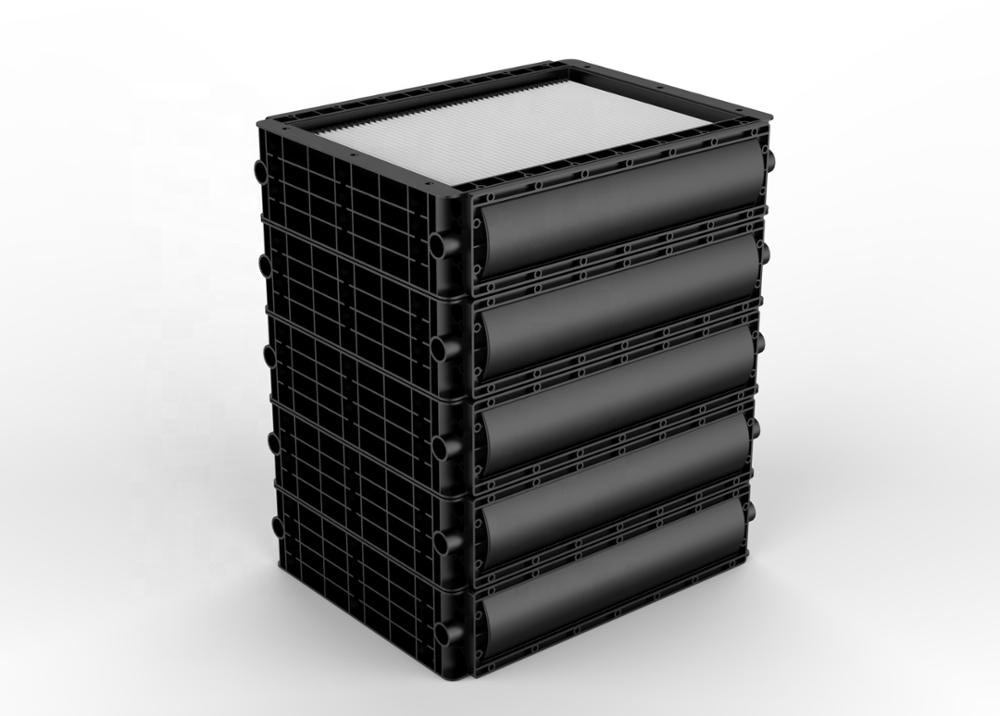

How to assemble the module?

A module is equipped with up to 50 exchangeable ceramic plates and a total membrane surface area up to 8m². A single module or up to 15 modules can be stacked up to a tower.

Installation Instructions

Company Introduction

SiHYFLUX Co.,Ltd has been researching and developing silicon carbide membrane since 2015. At present, our company has a product and R&D workshop of 4000 square meters.The production capacity will reach 30000 square meters per year, which is the biggest silicon carbide flat sheet membrane manufacturer in China.The products are sold at home and abroad, and have been run in different working conditions, such as Sinopec Group and TianJin Desalination Institute.In terms of treating highly difficult wastewater, the key technical indicators have reached the international leading level.

Hot Searches