Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

1450 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HEGU

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

25mx3mx3m

-

Power (kW):

-

37

-

Weight:

-

8T

-

Raw material:

-

PE/PP/PVC+wood powder+additives

-

Processing Type:

-

Thermal extrusion

-

Product Type:

-

WPC profiles

-

Product:

-

Floor, fence, roof, deck, door, frame, etc.

-

Advantages:

-

Water, sound & heat insulation, high stress, and long using life, etc

-

Color:

-

Original, wood, traditional red, etc

-

Surface treatment:

-

Sanding, brushing, embossing, graving, laminating, etc

-

Power(W):

-

90~150KW

-

Main motor:

-

Siemens

-

Inventer:

-

ABB

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Turkey, United Kingdom, Germany, Viet Nam, Philippines, Saudi Arabia, Pakistan, India, Mexico, Russia, Spain, Thailand, Malaysia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan

-

Certification:

-

CE

-

Marketing Type:

-

Hot Product 2019

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

22:1

-

Screw diameter (mm):

-

65 mm

-

Screw Speed (rpm):

-

1450 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HEGU

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

25mx3mx3m

-

Power (kW):

-

37

-

Weight:

-

8T

-

Raw material:

-

PE/PP/PVC+wood powder+additives

-

Processing Type:

-

Thermal extrusion

-

Product Type:

-

WPC profiles

-

Product:

-

Floor, fence, roof, deck, door, frame, etc.

-

Advantages:

-

Water, sound & heat insulation, high stress, and long using life, etc

-

Color:

-

Original, wood, traditional red, etc

-

Surface treatment:

-

Sanding, brushing, embossing, graving, laminating, etc

-

Power(W):

-

90~150KW

-

Main motor:

-

Siemens

-

Inventer:

-

ABB

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Turkey, United Kingdom, Germany, Viet Nam, Philippines, Saudi Arabia, Pakistan, India, Mexico, Russia, Spain, Thailand, Malaysia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan

-

Certification:

-

CE

-

Marketing Type:

-

Hot Product 2019

Product Description

New PE WPC decoration wall panel profiles making machine co-extrusion production line

This WPC machine is used for making WPC profiles by Wood and Plastic composition, such as WPC decking, WPC wall cladding, WPC fencing, WPC pergola, WPC post, etc... Using Waste wood and Waste plastic WPC wood plastic machine for making WPC decking and profiles

Raw material:

Using Waste wood and Waste plastic WPC wood plastic machine for making WPC decking and profiles

|

Plastic material

|

recyccled PP/PE plastic

|

|

Wood material

|

wood powder from rice husk/straw,wheat husk/straw,wood sawdust,wastage wood

|

|

Percentage of plastic

|

25-30%

|

|

Percentage of wood powder

|

50-70%

|

|

Final product

|

WPC decking, WPC wall cladding, WPC pergola profile, WPC fence profile, and other WPC construction profiles

|

|

Production process

|

raw material--mixing--granulation--extrusion and molding--surface treatment

|

WPC plant Cost

WPC plant cost:

Complete plant for Using Waste wood and Waste plastic WPC wood plastic machine for making WPC decking and profiles

|

WPC plant

|

Smallest WPC plant

|

Bigger WPC plant

|

Grow WPC plant

|

Economic WPC plant

|

|

Approximately machine cost

|

1200-1500 kgs daily production (24 hours running)

|

3000-3600 kgs daily production (24 hours running

|

6000-7000 kgs daily production (24 hours running)

|

9000-10000 kgs daily production (24hours running)

|

|

Approximately production capacity

|

80000-110000 USD

|

120000-160000 USD

|

150000-220000 USD

|

230000-360000 USD

|

|

Suggested mini factory size

|

500 square meter

|

800 square meter

|

1000 square meter

|

1200 square meter

|

|

Approximately installation power

|

200-300 kw

|

300-400kw

|

350-500kw

|

500-650 kw

|

Machine Images

1, WPC granulation machine

After get ready wood powder and recycled PP/PE plastic, the first step is mixing them with chemicals, then use WPC granulation machine to make WPC granules

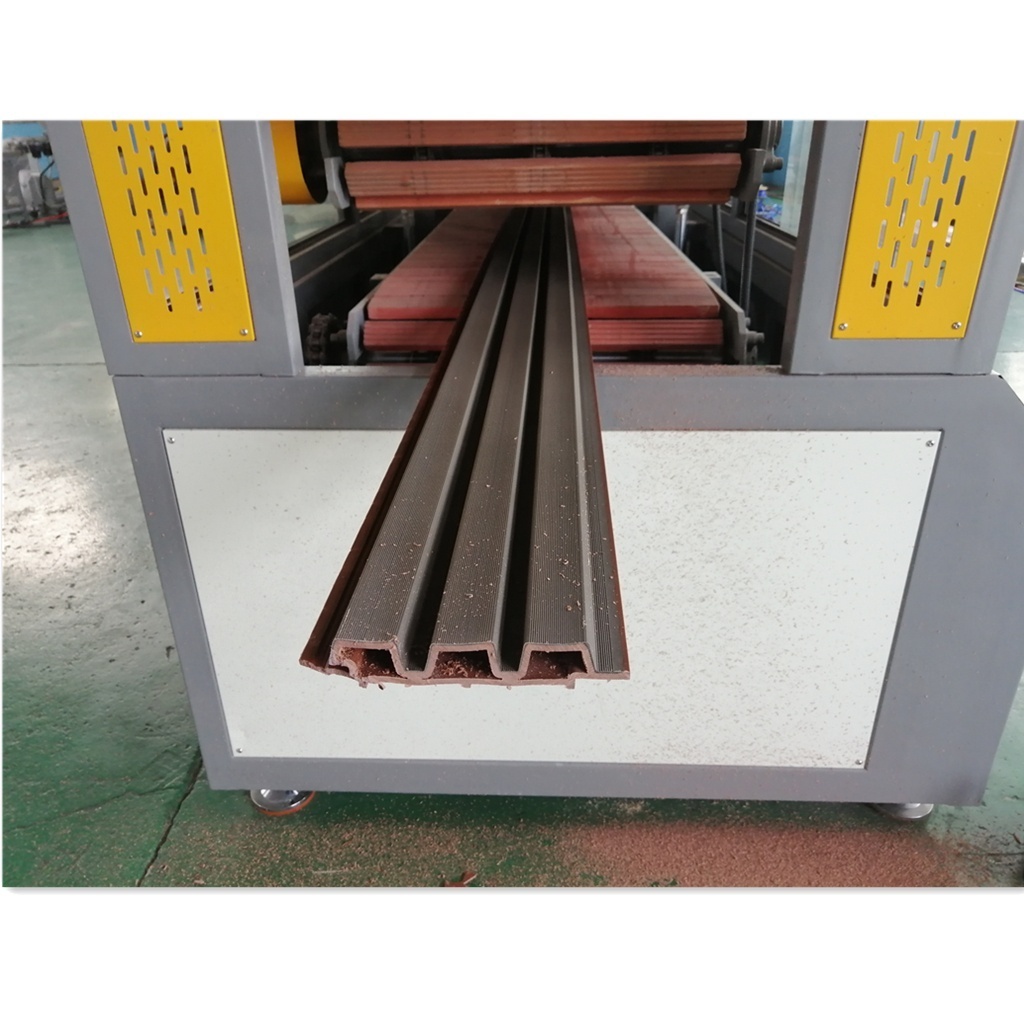

2, WPC profile extrusion line

The WPC profile extrusion line can make WPC granules into WPC products by equipping required mold, we can equip co-extrusion system and online 3D embossing device for making WPC products in high quality with wooden grain, the line also equipped with online cutting device.

PE WPC co-extrusion mold

Good quality wpc wall panel

WPC product wood surface making machine

Embossing machine, sanding machine, brushing machine, online embossing machine. these machines is for making WPC products with better wooden feeling design.

High quality extruders in workshop, wpc door extrusion line, WPC board extrusion line, WPC profile extrusion line, WPC decking extrusion line, WPC granulation line.

WPC profile extrusion lines in stock

Company profile

PE WPC granulating making machine

PE WPC profiles making machine

PVC WPC profiles making machine

PVC WPC door panel making machine

PVC WPC foaming board making machine

Hot Searches