- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

315

-

Weight (KG):

-

18500

-

Raw material:

-

Scrap Metal Steel

-

Max feeding size:

-

200-1020 mm

-

Output size:

-

10-60 mm

-

Spare parts:

-

Hammer Blades

-

Hammer materials:

-

alloy steel

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

Hot Product

-

Brand Name:

-

Derui Brand

-

Power (kW):

-

315

-

Weight (KG):

-

18500

-

Raw material:

-

Scrap Metal Steel

-

Max feeding size:

-

200-1020 mm

-

Output size:

-

10-60 mm

-

Spare parts:

-

Hammer Blades

-

Hammer materials:

-

alloy steel

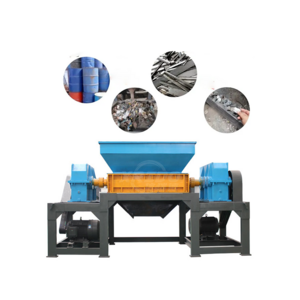

hydraulic metal crusher heavy duty

Scrap Metal Crusher Shredder is widely used to crusher all kinds of metal scraps like pop cans, paint bottles, waste aluminum, scrap copper wire/cables, waste bicycle, motorcycles, car shells, home appliances, electric waste, color tile sheet, oil drum etc.

It is with easy maintenance, simple structure, and powerful capacity. In the processing of crush, the rust, paint and other waste materials which adhering to the surface of the scrap metals will be removed. Then under the working force of magnetic sorting devices, the nonmetallic wastes that mixed in the scraps will be sorted out, including non-ferrous metals, plastic and rubber etc...

The final product is easier in delivery and shipping, conveniently steel-making, shortening time of smelting, and greatly improve the efficiency of iron and steel smelting.

Our scrap shredder can process materials as below:

- toxic hazardous industrial waste

- industrial waste

- solid urban waste

- bulky waste

- electronic equipment waste

- refrigerator recycling

- waste tires

- plastic recycling

- glas and rock wool

- paper shredding recycling

- hospital waste

- oil filter recycling

- Garbage

- Wood Pallet

Metal Hammer Shredder is usually composed of feed inlet, pre-pressing device (optional), rotor disc, motor, machine case, bottom frame (depending on the model).

In the scrap metal process line, except the main shredder machine, there are metal feed conveyor, discharge conveyor, vibration bench, magnetic separator and dust collecting system.

T he material after crusher treatment will be separated from other substances by magnetic separator to reduce the impurities o f the finished product. In addition, the p lant will be equipped with a dust removal device to reduce the pollution of dust particles during the scrap crushing process.

These auxiliary machines can be made based on client local requirements.

|

Model |

Max feeding size |

Dimension(L*H*W)m |

Output |

Power(kw) |

Coverage(m²) |

|

600 |

600*350mm |

2.0*2.2*1.6 |

500kg/h |

18.5-22 |

28 |

|

800 |

800*350mm |

2.2*2.4*1.8 |

1000kg/h |

37 |

28 |

|

1000 |

1.0*0.65m |

2.8*2.6*2.2 |

1.2-1.5t/h |

55 |

40 |

|

1000 |

1.0*0.65m |

3.2*2.8*2.0 |

2-2.5t/h |

75 |

45 |

|

1300 |

1.3*0.8m |

3.5*3.2*2.1 |

2.5-4t/h |

90-110 |

45 |

|

1600 |

1.6*0.8m |

3.8*3.4*2.4 |

5-6t/h |

110-132 |

50 |

|

1800 |

1.8*0.8m |

4.0*3.6*2.6 |

6-8t/h |

132-160 |

55 |

|

2000 |

2.0*0.8m |

4.2*3.6*2.8 |

8-10t/h |

200-220 |

80 |

1. Pre-sale support

1) We offer the best solution according to client’s requirement in time.

2) We accept and respect client’s creative idea. We will try our best to integrate client’s idea into the machine and take our years of experience into consideration.

3) We accept client’s sample materials sending for test and take videos.

4) We could offer our technical design before the purchase order.

2. After-sale service

1) Our skilled technicians are available for on-site installation, commissioning & training on request.

2) Dimensional drawings together with service requirements will be provided prior to delivery of the equipment.

3) An adequate inventory of spare parts and efficient service personnel are available for emergency case. Customers should keep the critical spare parts, like crusher knife and screen, so that we could get to know the spare parts you need.

4) Our guarantee period is 24 months. Within the guarantee period the broken parts (excluding quick-wear parts) can be exchanged with our new parts if it is not caused by human factors. And technicians are available for solving big problems overseas. Beyond the guarantee period the broken parts dispatched are charged at cost price.

5) Other after-sale service terms are negotiable.

1) Are you a factory or trade company?

We are professional recycling shredder factory with the modernized management and quality control system, experienced production team, advanced manufacturing and processing facility. Export proportion around 50%. .

2) How can I trust your company?

a. modernized management and quality control system, experienced production team, advanced manufacturing and processing facility.

b. Welcome to inspect anytime.

c. About the machine, we do much better on: Wear plates, seals, structure design, pressure head.

3) How about the garbage bag shredder test running & installation?

Before the order, welcome you to come to testing all machines in our factory, we have ready machines all the time. Before shipping out your machines, we will invite you to come to test your machines, when you are satisfied; we start to pack and delivery.

4) Any warranty?

Under the proper usage, 1year for whole garbage bag shredder.

5) Is your price competitive?

Only good quality machine we supply. Surely we will give you best factory price based on superior product and service.