- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Weight:

-

different

-

Warranty:

-

12 months

-

Number of layer:

-

1

-

Headbox type:

-

special turbulence generator

-

Pond width:

-

2.900 mm

-

Jet velocity (design):

-

1.200 m/min

-

Stock consistency:

-

approx. 0.20 to 0.30%

-

Retention:

-

approx. 50 to 65%

-

Max. suspension temper:

-

60 °C

-

Stock supply to the distributor:

-

drive side

Quick Details

-

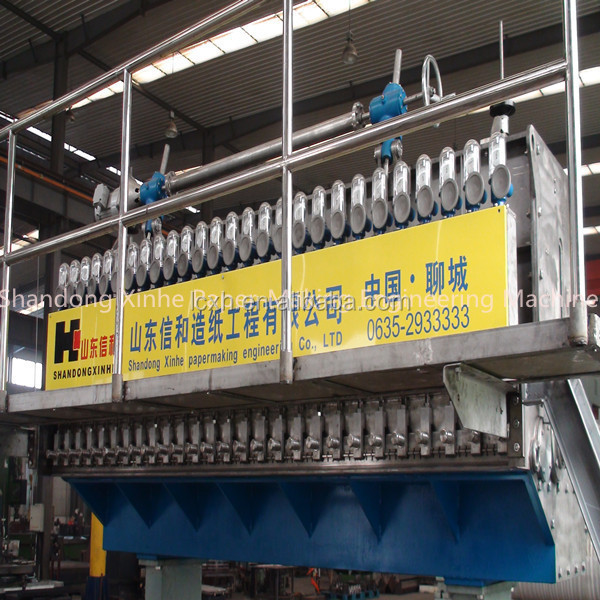

Place of Origin:

-

Shandong, China

-

Brand Name:

-

COMER & XINHE

-

Model Number:

-

Cyberflow-S

-

Voltage:

-

380V

-

Weight:

-

different

-

Warranty:

-

12 months

-

Number of layer:

-

1

-

Headbox type:

-

special turbulence generator

-

Pond width:

-

2.900 mm

-

Jet velocity (design):

-

1.200 m/min

-

Stock consistency:

-

approx. 0.20 to 0.30%

-

Retention:

-

approx. 50 to 65%

-

Max. suspension temper:

-

60 °C

-

Stock supply to the distributor:

-

drive side

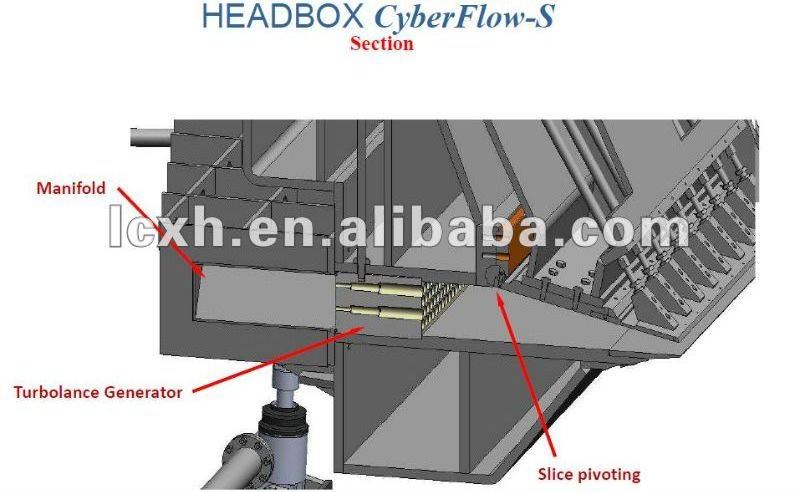

1.Changeable insert turbulent generator

2.Micro-adjuster

3.Easy to operate

Air-cushioned headbox for paper pulping equipment

1.Brief introduction:

Headbox is the key of paper machine,the function is supplying uniform and steady pulp flow to paper machine wire part. Different pulp, different machine speed, different flow the design of headbox is different. So when choose headbox, please pay more attention. Our company design and produce headbox according to the informaiton of our customer’s paper making machine, calculate and design with the help of computer,. Thus, our headbox can meet customer’s requirements and obtain the best using effect, with good formation of paper web, small cross basic weight difference.

2.Air-cushioned Headbox with Double Rectifier Rolls Controlled by Computer

This production is the airtight air-cushioned pressurized headbox with single rectifier roll, used for fourdrinier.

The distributor of the headbox consists of rectangular tapered inlet header for feeding pulp and step diffuser for distributing pulp. The evener device consists of two floor plates and a rectifier roll. The articulated top slice with a micro-adjustor is used as nozzle system. The micro-adjustor has dial indicator for displaying and accurate gearbox for adjusting. The top slice is adjusted by manual worm gearbox. The maximum opening of the top slice is big than 80~100mm, which is easy to clean and maintain. The top slice is adjusted by manual worm gearbox smoothly and easily.

3.Specification and Performance

· This is the patent product, which is suitable for wide range of machine speed and basis weight.

· Adaptive speed: 100~500M/min (designed on requirements)

· Apply to high consistency stock

· Rigid top slice and apron board

· Tapered header and step diffuser distribute the stock evenly. A pressure balance indicator is mounted on the tapered header.

· Micro-adjustor of slice lip with dial indicators

· Adjustable basement

· Shifter of top slice for horizontal moving is just used for double joint type, to adjust the jet exit angle and the point of impact.

· The total pressure and stock level is controlled by computer.

· Easy and safe operation,Modern equipment

3.Advantages:

Compared with traditional headbox,the air cushioned dilution water headbox has notably advantages eg:

It can achieve better basis weight profile,make the fibre more uniformly distributed,

and the pulp go through rectifier zone to turbulence generator ,to prevent fibre floculation,and eventually result in uniform sheet formation.