- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Hotel

-

Design Style:

-

Contemporary

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YURU

-

Model Number:

-

single-126

-

Type:

-

waterproof coating, Other Waterproofing Materials

-

Shape:

-

Liquid

-

Format:

-

Liquid

-

Product Name:

-

Polyurethane Waterproof Coating

-

Color:

-

Colorful

-

Usage:

-

Building Coating

-

Certificates:

-

ISO9001-2008

-

Application Method:

-

Roller

-

Feature:

-

Eco Friendly

-

Function:

-

Contruction Waterproof

Quick Details

-

Warranty:

-

5 years

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

total solution for projects, Others

-

Application:

-

Hotel

-

Design Style:

-

Contemporary

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YURU

-

Model Number:

-

single-126

-

Type:

-

waterproof coating, Other Waterproofing Materials

-

Shape:

-

Liquid

-

Format:

-

Liquid

-

Product Name:

-

Polyurethane Waterproof Coating

-

Color:

-

Colorful

-

Usage:

-

Building Coating

-

Certificates:

-

ISO9001-2008

-

Application Method:

-

Roller

-

Feature:

-

Eco Friendly

-

Function:

-

Contruction Waterproof

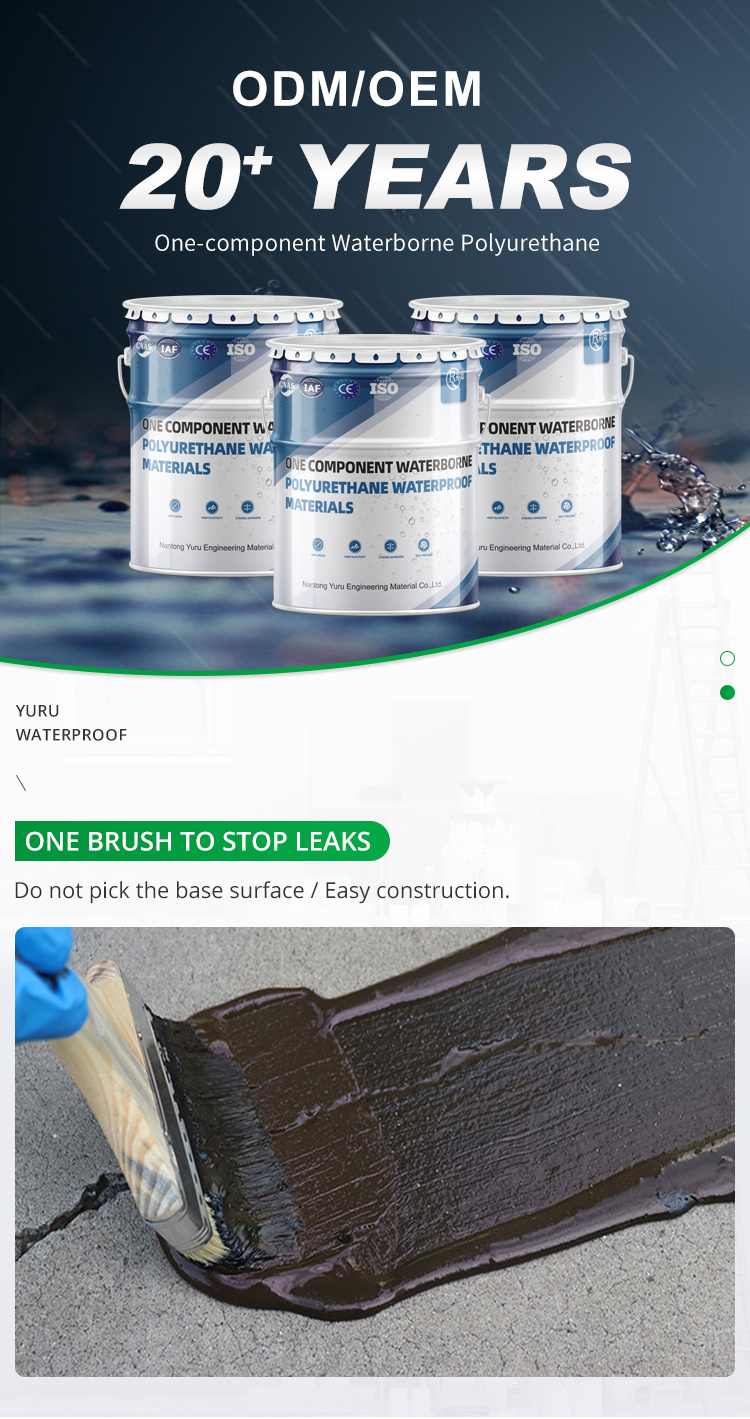

OEM Service

Product description

One component waterborne polyurethane waterproof materials

1. Product introduction

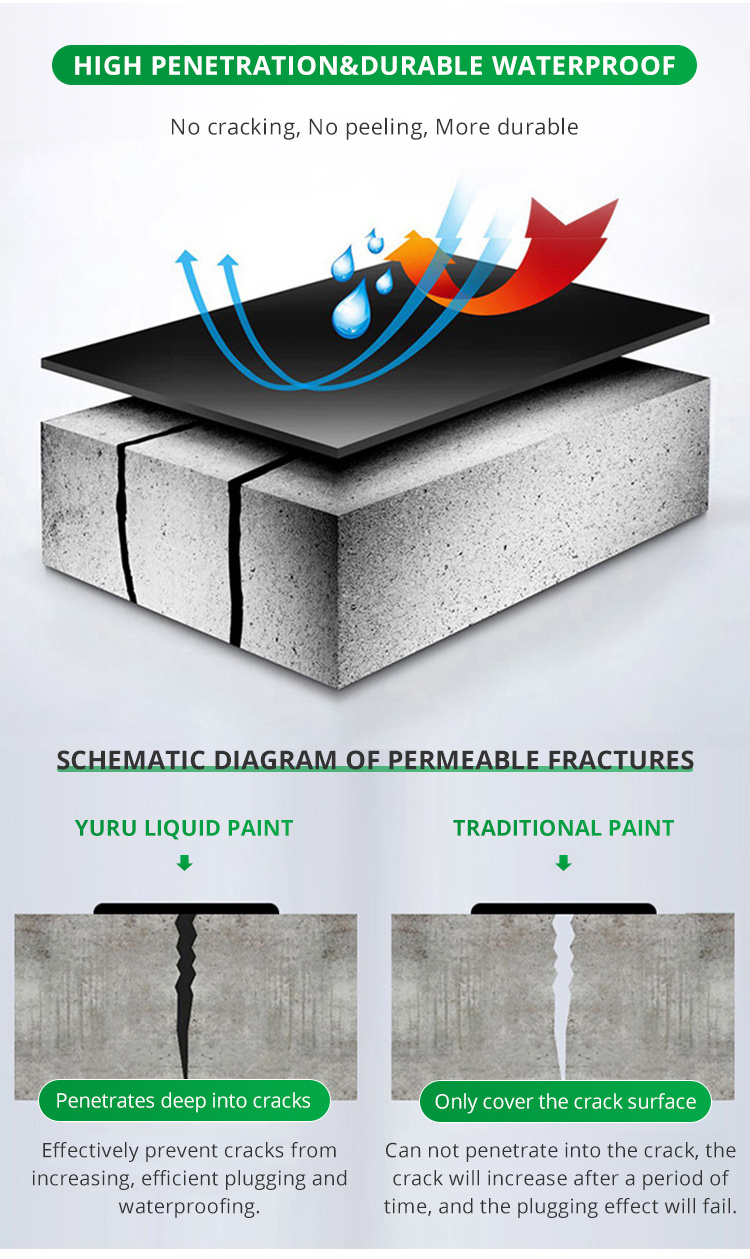

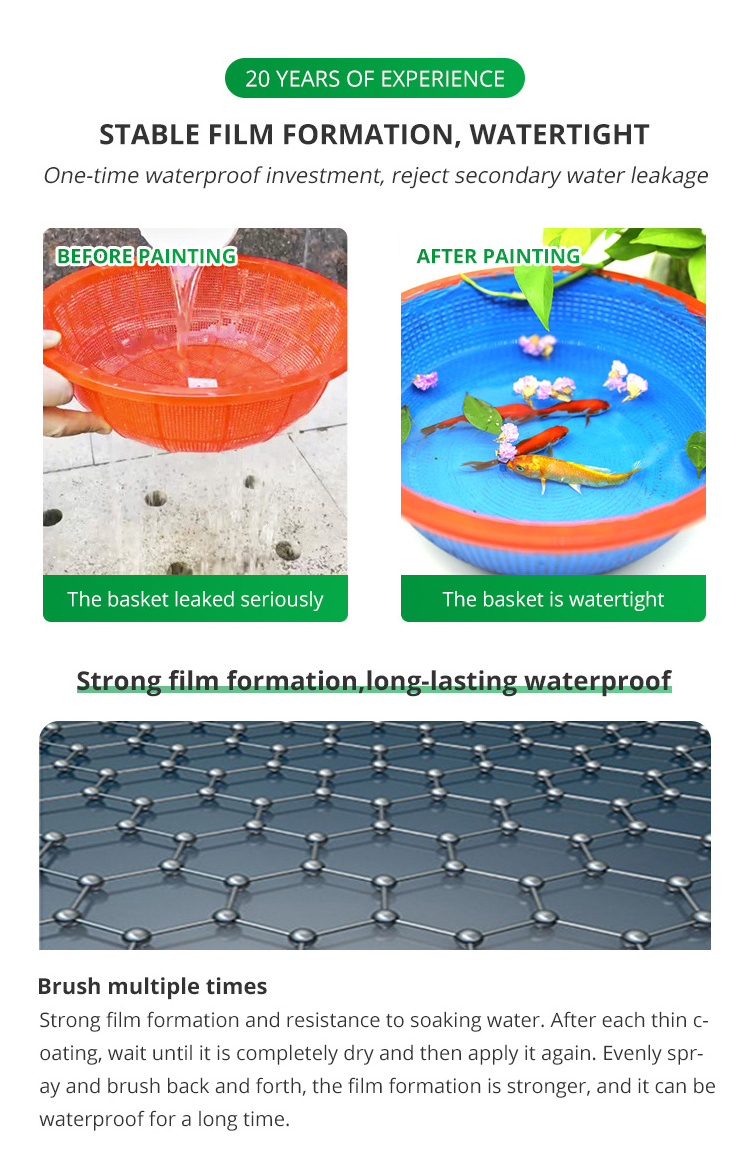

Single component waterborne polyurethane waterproof coating belongs to the chemical reaction type material, made of polymer and asphalt materials through special process, can dissolve in water compound waterproof material, coating material scraping and waterproof engineering base through the air and UV light curing a rubber like elastic coating, good waterproof material film, anti aging performance can be better

2. Advantages

After the formation of the film without joints, the integrity of the elastic waterproof layer, strong bonding strength, weathering and anti-aging properties, single group to overcome the construction of the two groups of the allocation ratio and mixing process errors, is the ideal material for construction

|

NO.

|

Pilot projects

|

|

Index

|

|

||

|

|

|

|

I

|

II

|

||

|

1

|

Tensile Strength,Mpa≥

|

|

1.0

|

1.5

|

||

|

2

|

Elongation at break,%≥

|

|

300

|

|

||

|

3

|

Impermeable,(0.3Mpa,30min)

|

|

Impermeable

|

|

||

|

4

|

Solid content,%≥

|

|

65

|

|

||

|

5

|

Low temperature flexibility, bend 180° around Φ10mm rod

|

|

-10℃, no cracks

|

-20℃, no cracks

|

||

|

6

|

Drying time,h

|

Tack-free time,≤

|

4

|

|

||

|

|

|

Hard work time,≤

|

8

|

|

||

|

7 |

Tensile strength retention rate after treatment,% |

Heat treatment≥

|

80

|

|

||

|

|

|

Alkali treatment≥

|

60

|

|

||

|

|

|

Acid treatment≥

|

40

|

|

||

|

|

|

Artificial weathering treatment ª

|

--

|

80~150

|

||

|

8 |

Elongation at break after treatment,% |

Heat treatment≥

|

200 |

|

||

|

|

|

Alkali treatment≥

|

|

|

||

|

|

|

Acid treatment≥

|

|

|

||

|

|

|

Artificial weathering treatment ª≥

|

--

|

200

|

||

|

9

|

Heat shrinkage,%

|

Elongation≤

|

1.0

|

|

||

|

|

|

Shorten≤

|

1.0

|

|

||

Hot Searches