- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Sincola for dry mortar plant

-

Voltage:

-

380v/50hz

-

Power:

-

2.2kw-18.5kw

-

Dimension(L*W*H):

-

as shown in table

-

Weight:

-

4000 kg

-

Features:

-

Simple type

-

Product name:

-

Dry Mortar Plant

-

Output capacity:

-

1,3,5,10 ton per hour

-

Packing method:

-

automatic filling,weighing into bag

-

Equipment height:

-

5-9M

-

Occupied area:

-

20-100M3

-

small type dry mortar plant:

-

1-5T/H

-

Manpower:

-

2-3 people

-

Advantage:

-

Convenient Operation

-

Batching and weighting:

-

Manual+simple Automatic

-

Raw material:

-

Lime Powder Chemicals Cement Sand

Quick Details

-

Marketing Type:

-

New Product 2022

-

Application:

-

Dry Mortar Powder Mixing Produce packing

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Sincola for dry mortar plant

-

Voltage:

-

380v/50hz

-

Power:

-

2.2kw-18.5kw

-

Dimension(L*W*H):

-

as shown in table

-

Weight:

-

4000 kg

-

Features:

-

Simple type

-

Product name:

-

Dry Mortar Plant

-

Output capacity:

-

1,3,5,10 ton per hour

-

Packing method:

-

automatic filling,weighing into bag

-

Equipment height:

-

5-9M

-

Occupied area:

-

20-100M3

-

small type dry mortar plant:

-

1-5T/H

-

Manpower:

-

2-3 people

-

Advantage:

-

Convenient Operation

-

Batching and weighting:

-

Manual+simple Automatic

-

Raw material:

-

Lime Powder Chemicals Cement Sand

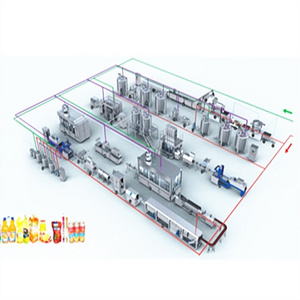

2022 China New Technology Full Automatic Cement Glue/Putty Powder Dry Mix Mortar Production Line Machine Equipment Manufacturer

Products Description

Product Description of 1-5t/h Capacity Tile Adhesive Mortar Production Equipment

Simple and practical small type dry mortar plant is designed based on the traditional mixer, is added a material conveying system,a storage bin and an automatic filling machine. The well-mixed materials will go into the storage bin via material conveying pipe,and the mixer may be feed consecutively and work continuously in flow line production, but the equipment is not over 4 meters high, thus solving the problem of heightening the workshop. Moreover, it may realize automatic metering and filling, hence, it may not merely save the time and energies but also may be more accurate. Requiring little investment, but it may load, weight and package the materials automatically; no wondering, it is a simple but practical production line.

Simple and practical small type dry mortar plant is designed based on the traditional mixer, is added a material conveying system,a storage bin and an automatic filling machine. The well-mixed materials will go into the storage bin via material conveying pipe,and the mixer may be feed consecutively and work continuously in flow line production, but the equipment is not over 4 meters high, thus solving the problem of heightening the workshop. Moreover, it may realize automatic metering and filling, hence, it may not merely save the time and energies but also may be more accurate. Requiring little investment, but it may load, weight and package the materials automatically; no wondering, it is a simple but practical production line.

|

Mode

|

Capacity

|

Area

(Square meters)

|

Height

|

Note

|

|

Simple

|

1-5t/h

|

40

|

3m

|

Manual batching and packing

|

|

Basic

|

5-15t/h

|

40-60

|

6-10m

|

Manual batching ,automatic packing

|

|

Semi Automatic Serial

|

5-15t/h

|

40-80

|

8-12m

|

Automatic batching of coarse material,manual

batching of additive ,automatic packing |

|

Full Automatic

|

5-50t/h

|

40-100

|

10-25m

|

Automatic batching of coarse material,manual

batching of additive,automatic packing |

|

Full Automatic Tower

|

55-100t/h

|

60-500

|

10-30m

|

Automatic batching of coarse material,manual

batching of additive,automatic packing |

Application

1)Dry mortar

2) Insulation mortar

3) Putty powder

4) Masonry mortar

5) Thin and Smooth wall mortar

6) Water proof mortar

7) Plaster powder

8) Wall plastering mortar

9) Ceramic tile adhensive mortar

2) Insulation mortar

3) Putty powder

4) Masonry mortar

5) Thin and Smooth wall mortar

6) Water proof mortar

7) Plaster powder

8) Wall plastering mortar

9) Ceramic tile adhensive mortar

Product packaging

Hot Searches