- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Ascend

-

Dimension(L*W*H):

-

4600x1700x2200mm

-

Weight:

-

2000 KG

-

Marketing Type:

-

Hot Product 2021

-

Product name:

-

diesel jaw crushing machine

-

Name:

-

Mobile diesel crusher jaw machine

-

Keyword:

-

Fine Stone Jaw Crusher

-

The Machines classification:

-

Quartz Sand Equipment

-

Output size:

-

3-10mm

-

Max feeding size:

-

25mm

-

After-sales Service Provided:

-

1 Year

-

Power:

-

22-110KW

Quick Details

-

Application:

-

Gold Mining

-

Capacity(t/h):

-

20-30

-

Place of Origin:

-

Henan, China (Mainland)

-

Brand Name:

-

Ascend

-

Dimension(L*W*H):

-

4600x1700x2200mm

-

Weight:

-

2000 KG

-

Marketing Type:

-

Hot Product 2021

-

Product name:

-

diesel jaw crushing machine

-

Name:

-

Mobile diesel crusher jaw machine

-

Keyword:

-

Fine Stone Jaw Crusher

-

The Machines classification:

-

Quartz Sand Equipment

-

Output size:

-

3-10mm

-

Max feeding size:

-

25mm

-

After-sales Service Provided:

-

1 Year

-

Power:

-

22-110KW

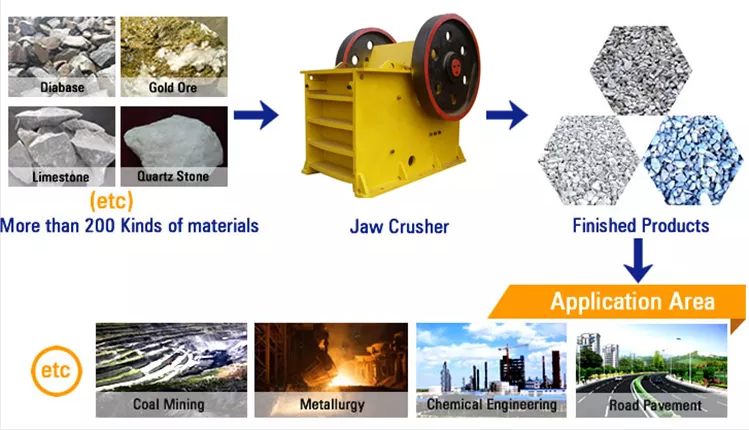

Mobile portable diesel engine rock stone small jaw crusher crushing plant

Diesel mobile jaw crusher is widely used for crushing various materials like stone, granite, trap rock, coke, coal, manganese ore, iron ore, emery, fused aluminum, oxide, fused calcium carbide, lime stone, quartzite, alloys, etc. The application of tires makes the machine more convenient to move and adapt to various application, especially when your place lack of electricity or you need to move machines frequently.

The electromotor drives the belt and pulley to make the movable jaw move back and forth, up and down through the eccentric shaft. The raw material is squashed or splitt when movable jaw plate moves towards fixed jaw together with movable jaw. When movable jaw and movable jaw plate turn back by eccentric shaft and spring, the raw material, which is squashed or split before discharges from the bottom outlet under jaw plate.

| SC Jaw crusher | SC600 | SC750 | SC900 | SC1060 | SC1200 | SC1300PEX |

| Transport dimension | ||||||

| Length (mm) | 8600 | 9600 | 11097 | 13300 | 15800 | 9460 |

| Width (mm) | 2520 | 2520 | 3759 | 2900 | 2900 | 2743 |

| Height (mm) | 3770 | 3500 | 3500 | 4440 | 4500 | 3988 |

| Weight (Kg) | 15240 | 22000 | 32270 | 57880 | 98000 | 25220 |

| Axle load(kg) | 10121 | 14500 | 21380 | 38430 | 64000 | 14730 |

| Traction pin load(kg) | 5118 | 7500 | 10890 | 19450 | 34000 | 10490 |

| Jaw crusher | ||||||

| Model | PE400X600 | PE500X750 | PE600X900 | PE750X1060 | PE900X1200 | PEX300X1300 |

| Inlet size (mm) | 400X600 | 500X750 | 600X900 | 750X1060 | 900X1200 | 300X1300 |

| Adjustment range of discharge port (mm) | 40-100 | 50-100 | 65-180 | 80-180 | 95-225 | 20-90 |

| Capacity (m³/h) | 10-35 | 25-60 | 30-85 | 70-150 | 100-240 | 10-65 |

| Vibrating feeder | ||||||

| Hopper volume(m³) | 3 | 4 | 7 | 10 | 10 | 3 |

| Width of Hopper(mm) | 2200 | 2500 | 3000 | 3000 | 3000 | 2200 |

| Model | GZT0724 | GZT0724 | GZT0932Y | ZSW490X110 | ZSW600X130 | GZT0724 |

| Belt conveyor | ||||||

| Model | B650X6 | B800X7 | B1000X8 |

Advantages of mobile stone crusher pant.

1. Be movable and drive by diesel engine if the working site is limited

2. Deep crushing cavity, no dead zone, increasing capacity and output of the feeding

3. Large crushing ratio, uniform products particle size

4. Pad-style nesting population adjustment devices, and ease of adjustment range

5. Simple and reliable structure,low operation costs

6. The discharging size of jaw crusher can be adjusted to meet the requirements of different users

7. Low noise and less dust

1. Crushing Equipment: jaw crusher, impact crusher, cone crusher, hammer crusher, roller crusher, fine crusher, compound crusher, stone crushing production line, etc.

2. Mobile Crushing Plant: mobile jaw crusher, mobile impact crusher, mobile cone crusher, mobile VSI sand making plant, etc.

3. Grinding Equipment: ball mill, rod mill, raymond mill, wet pan mill , etc.

4. Sand and Gravel Equipment: sand maker, VSI sand making plant, bucket type sand washer, spiral sand washer, etc.

5. Gold ore project and solutions: mobile gold trommel plant, tank leaching, heap leaching, gold ore gravity separation line, CIL/CIP, etc.

6. Mineral Processing Equipment: spiral classifier, spiral chute, shaking table, jigging machine, centrifugal gold concentrator, leaching tank, magnetic separator, flotation machine, etc.