- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JSCS

-

IP rating:

-

IP68

-

Fluid Type:

-

Corrosive Fluid Level

-

Corrosive Material:

-

ABS Anticorrosive Material

-

Corrosive Material 2:

-

PTFE Line Level Gauge

-

Structure:

-

All in One

-

Principle:

-

Magnetic Sensors

-

Kind:

-

Float/Magnetic Flap

-

Feature:

-

Corrosion Resistant

-

Range:

-

0-15m

-

HS Code:

-

90261000

Quick Details

-

Grade:

-

DIY, Industrial

-

Warranty:

-

12 months

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JSCS

-

IP rating:

-

IP68

-

Fluid Type:

-

Corrosive Fluid Level

-

Corrosive Material:

-

ABS Anticorrosive Material

-

Corrosive Material 2:

-

PTFE Line Level Gauge

-

Structure:

-

All in One

-

Principle:

-

Magnetic Sensors

-

Kind:

-

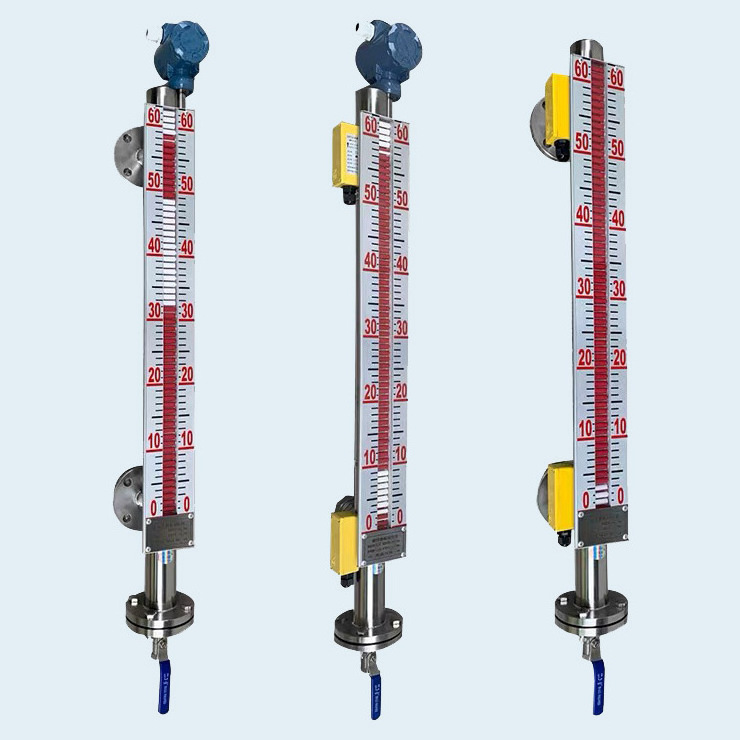

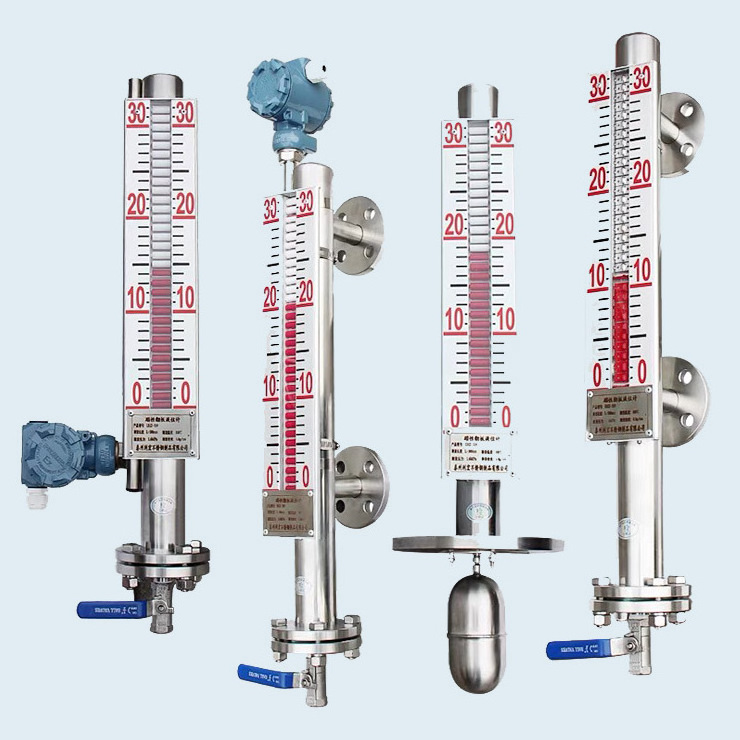

Float/Magnetic Flap

-

Feature:

-

Corrosion Resistant

-

Range:

-

0-15m

-

HS Code:

-

90261000

Product Description

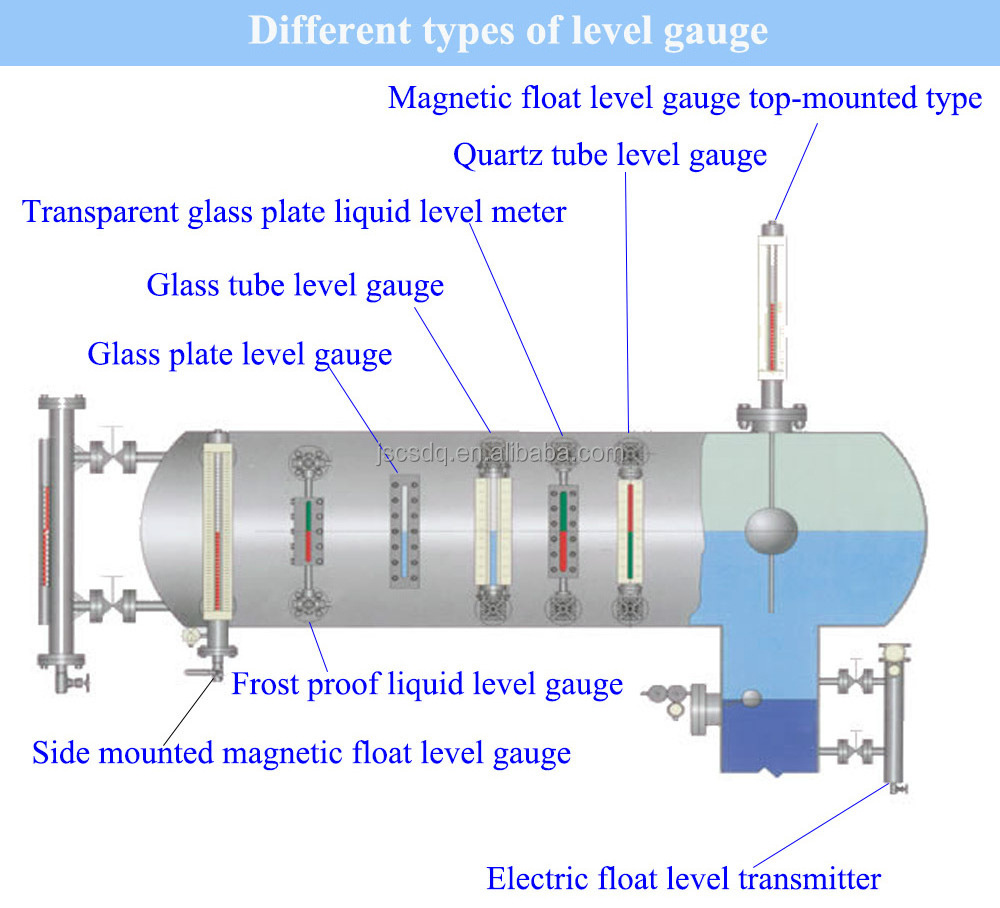

Magnetic Flap Water Level Meter Sight Glass Diesel Fuel Tank Level Gauge Transmitter

Level gauge the main components (body) in direct contact with the medium are made of stainless steel material or other special materials, indicating that components are not in contact with the media, and therefore containing

flammable, explosive, toxic,corrosive media container

use the gauge is safe and reliable.

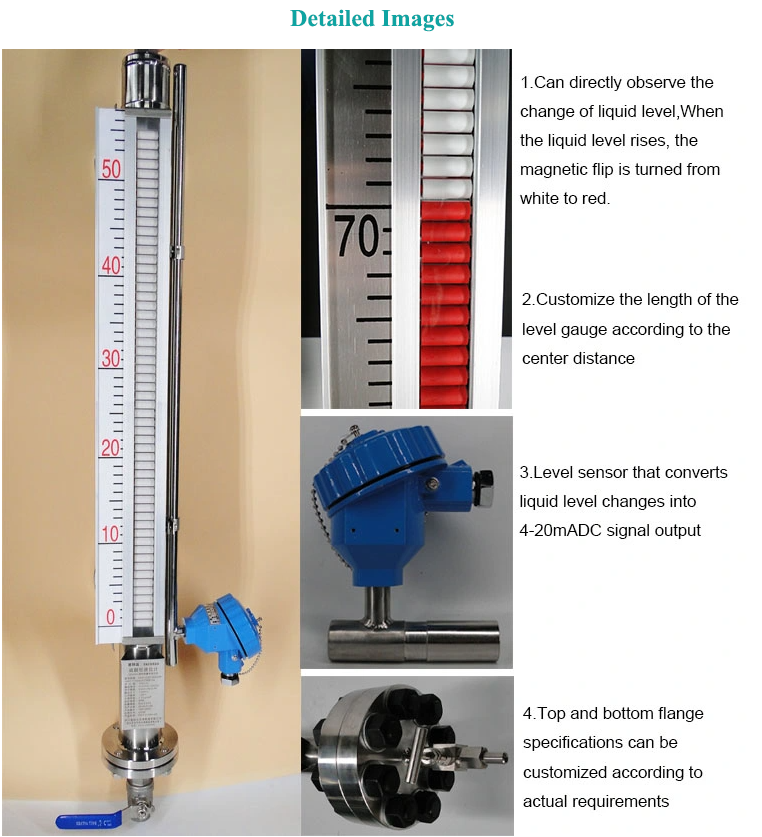

Two-color (white vapor, liquid red) turned columns, flap display, indicating continuous visual eye-catching, no blind spots, in any case will not be a false level.

Less sealing surface, reducing static seal leakage points above 95% , and thus, to overcome the petroleum, chemical industry pressure vessel parts run,run, drip, leak and other weak links than the original plate level gauge.

Simple structure, easy installation and maintenance, large-scale, design pressure, long life, wide range of application s.

Magnetic float level gauge, with a level gauge can replace more than one glass plate liquid level gauge, and the installation

extremely easy to use.

Two-color (white vapor, liquid red) turned columns, flap display, indicating continuous visual eye-catching, no blind spots, in any case will not be a false level.

Less sealing surface, reducing static seal leakage points above 95% , and thus, to overcome the petroleum, chemical industry pressure vessel parts run,run, drip, leak and other weak links than the original plate level gauge.

Simple structure, easy installation and maintenance, large-scale, design pressure, long life, wide range of application s.

Magnetic float level gauge, with a level gauge can replace more than one glass plate liquid level gauge, and the installation

extremely easy to use.

Meanwhile, the use of plant development level remote transmitter, alarm and automatic control device, can be realized on the lower level alarm and control automation.

Specification

|

Measure ranges

|

20-15000mm

|

|

Measure accuracy

|

± 5mm (can add magnetostrictive level transmitter, realize accuracy +/- 1mm)

|

|

Working pressure

|

1.0, 1.6, 2.5, 4.0, 6.4, 10.0, 16, 0MPa

|

|

Fluid temperature

|

-40~450ºC

|

|

Ffluid viscosity

|

≤ 14m/s

|

|

Fluid density

|

≥ 0.5g/cm3

|

|

Body or cage material

|

1Cr18Ni9Ti, 304SS, 316SS, 301SS, Carbon steel; Floater material: 304SS, 316SS, Titanium

|

|

Flange

|

Side flange, tank top flange; ANSI, JIS OR DIN form.

|

|

Transmitter output

|

4~20mA signal, add level switches (HH, H, L, LL) to realize remote control

|

|

Float Cage Material

|

SS304, SS316, PTFE, PP, PVC, PVDF

|

|

Max. Centre to Centre Distance

|

6000 mm, greater lengths on request

|

|

Connecting Flanges

|

According to DIN or ANSI B16.5

|

|

Temperature of Liquid

|

450ºC (Max.) for SS, 80ºC (Max.) for PVDF

60ºC (Max.) for PVC, 50ºC (Max.) for PP |

|

Specific Gravity

|

Min. 0.45

|

|

Scale

|

Graduated in cm, Aluminium or SS304

|

|

Measuring Accuracy

|

+/- 5 mm

|

Recommend Products

DCS & SIS CONTROL SYSTEM SUPPLY

Our Advantages

1. Integrating R&D, production, distributing and technical services

2. After Warranty Service

Site Installation and commissioning,

24 hours online support and Video technical support

Hot Searches