- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HuanLi

-

Name:

-

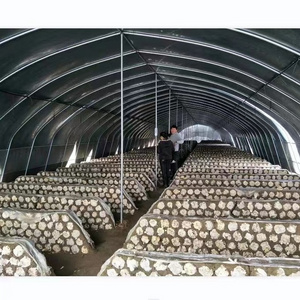

Greenhouse climate control system

-

Application:

-

Mushroom

-

After-sales Service Provided:

-

Overseas service center available

-

Features:

-

Economic

-

Usage:

-

Vegetables Growing

-

Optional system:

-

Cooling System.ventilation.etc

-

keyword:

-

mushroom cultivation machine

Quick Details

-

Size:

-

Large

-

Type:

-

Plastic Shed

-

Model Number:

-

HL-24HP

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HuanLi

-

Name:

-

Greenhouse climate control system

-

Application:

-

Mushroom

-

After-sales Service Provided:

-

Overseas service center available

-

Features:

-

Economic

-

Usage:

-

Vegetables Growing

-

Optional system:

-

Cooling System.ventilation.etc

-

keyword:

-

mushroom cultivation machine

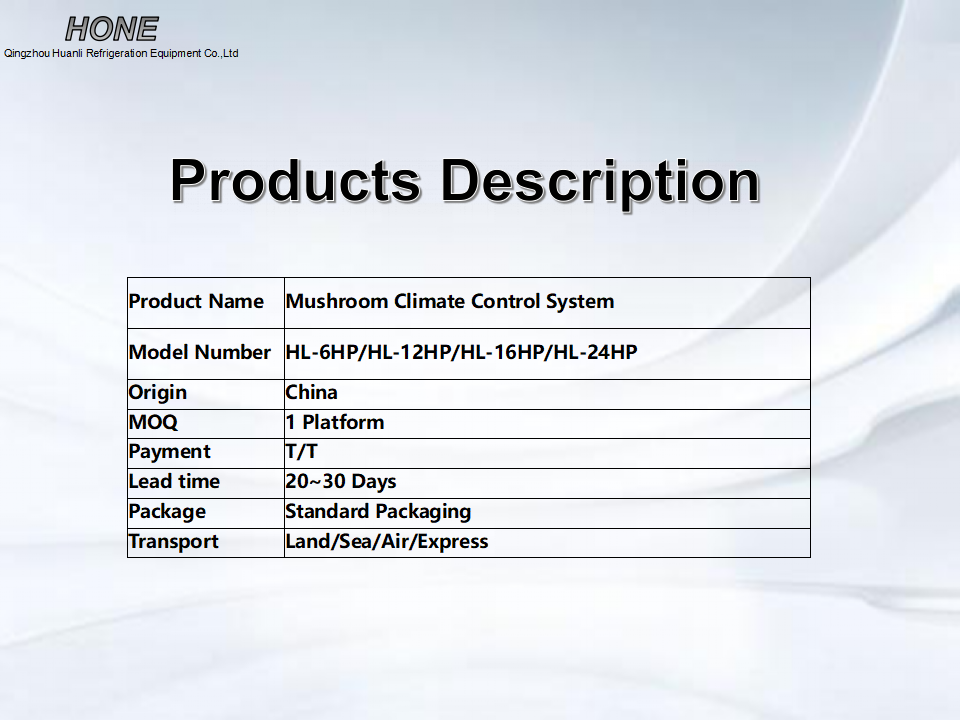

Product parameters

|

NO |

Name |

Model |

Qty |

|

1 |

Mushroom climate control machine |

HL-16HP |

1set |

|

2 |

Ultrasonic Humidifier |

28kgs/h |

1set |

|

3 |

Indoor PE bag air duct |

Dr:550mm |

6 |

|

4 |

Insulated pipe |

Thickness:20mm |

3m3 |

|

5 |

PVC-U pipes for humidity |

Dr:110mm |

14m |

|

6 |

Overpressure louver |

300x300mm |

2pcs |

|

7 |

Light |

L=1.2m |

8pcs |

|

8 |

Mushroom racks |

5x0.3m,4layers |

2sets |

|

9 |

Mushroom rack |

5x0.75m,4layers |

1set |

|

10 |

Container made by PU panels |

20ft |

1set |

|

11 |

Dry&web bulb |

/ |

1set |

|

12 |

PTC electric heating |

/ |

1set |

|

13 |

Frequency inverter |

/ |

1set |

|

14 |

Compost temperature sensor |

/ |

2pcs |

|

15 |

CO2 Control box box |

/ |

1set |

|

16 |

Outdoor Air duct |

/ |

1set |

|

17 |

Indoor air distribution box |

/ |

1set |

|

18 |

Electric cables and cable pipes |

/ |

1set |

|

19 |

Installation accessories (screws,glues ect) |

/ |

1set |

Product function

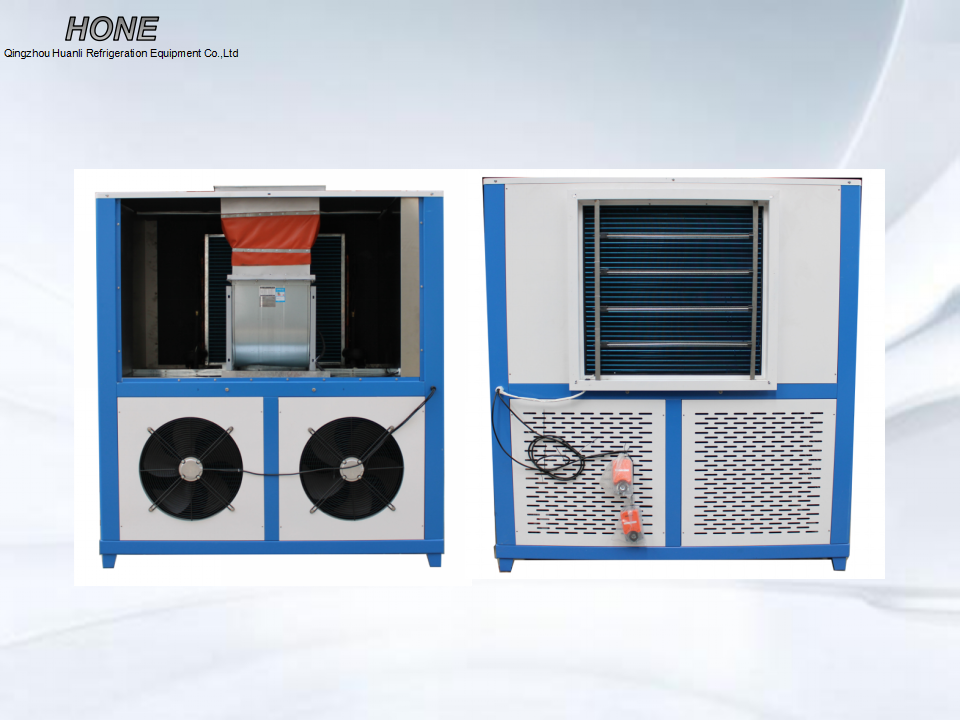

Individual Integrated Mushroom Climate Control Machine:

The machine consists of refrigeration compressor, condenser, evaporator, drying filter, gas-liquid separator, expansion valve, fresh air fan, air filter, centrifugal fan, control system and other major components.

1) The working principle of the mushroom climate control machine:

The refrigerant R22/R410A is compressed by the compressor, and is changed from a low-temperature low-pressure gas to a high-temperature high-pressure gas. The high-temperature high-pressure gas is cooled by exchange heat with the cooling water in the condenser, and becomes a normal-temperature high-pressure liquid. After the portion of the normal-temperature high-pressure liquid is filtered and dried by the filter, The gas is expanded into the expansion valve through the solenoid valve, so that the gas and liquid mixture at normal temperature and high pressure becomes a refrigerant saturated liquid of low temperature and low pressure, and the process is completed by utilizing the principle of gas expansion to absorb heat. Finally, the low temperature and low pressure refrigerant saturated liquid exchanges heat with the surrounding medium in the evaporator, so that the heat medium is cooled to become a cold medium, and the refrigerant saturated liquid itself becomes a low temperature and low pressure gas, which enters the compressor for compression, thereby forming a cycle.

2) Fresh air system: The fresh air is first filtered through the high efficient filter - mixing with the air in the mushroom room in the return air box - cooling by the evaporator - sent to the indoor air duct by the centrifugal fan, soft and natural fresh air is distributed to the mushroom house every corner.

3) Introduction to the advantages of the mushroom climate control machine:

a. The operation is simple and safe. The only wire control voltage that is in contact with the mushroom room is 24V, and there is no fire safety hazard.

b. The air supply is uniform, and the uniform PE film air duct is used for air supply. The temperature difference between the mushroom houses is ±0.5 °C, creating a balanced growth environment throughout the mushroom room.

c. The fresh air is purified by the junior efficient filter and pre-cooled (heat), which will not cause irritation to the mushrooms.

d. The return air filter function makes the bacteria package not easy to be contaminated.

e. Control system with CO2, humidity, temperature, illuminance, and internal circulation.

f. With automatic detection of faults, reducing repair time.

g. The integral structure, the indoor unit, the outdoor unit, the control system, and the fresh air system are integrated, and only need to be connected with the power source and the air duct. The whole machine is 100% tested in the factory, and the quality is better and more reliable.

4) Introduction to the performance of the mushroom climate control machine:

a. The unit is a completely independent integrated unit, which is assembled and tested by the factory assembly line.

b. Frame structure: made of steel, each part is pre-treated with zinc phosphate and then sprayed with polyester powder; the components and pipelines of the unit are equipped with reinforced support and hoisting sheet metal.

c. refrigeration unit features:

1)The design is novel and beautiful, the structure is light and reasonable, and easy for installation;

2) Brand compresor, large cooling capacity, outstanding reliability, and can work continuously for a long time;

3)High-pressure centrifugal air-proof fan is adopted, which has long air supply distance and low power consumption;

4)Simple system structure, accurate and reliable control.

d. Full-hermetic series compressor: It adopts high efficiency and environmentally friendly scroll compressor with high efficiency and low noise; small volume and light weight; stable operation and long compressor life.

e. CO2 centralized control system through the air sampler to sample the room air to the outdoor dry filter for detection, not only avoids the problem of CO2 sensor in the high humidity environment easily damaged, and multiple rooms use a CO2 sensor turning detection greatly saves customers' costs. (optional accessory)

f. evaporator: using corrosion resistance hydrophilic aluminum fin fins

g. throttling device: throttling element / key valve parts using foreign famous brand expansion valve

h. HuanLi energy-saving system (total energy saving can reach more than 20%)

Qingzhou Huanli Refrigeration Equipment Co., Ltd. is a professional manufacturer of refrigeration and air treatment equipment in Mainland China. Founded in 2008, the company is a high-tech enterprise integrating science, industry and trade, creating a natural living space and subtle exquisiteness. The production environment is our responsibility. We are committed to the R&D and production of refrigeration and air treatment equipment required by industries, businesses, military and other industries. It is a high-tech enterprise integrating research, production and trade.At the end of 2013,in order to further improve the technical level of the company's products and meet the requirements of energy conservation and environmental protection in the international community, the company invested in the production of production equipment,mainly producing heat recovery series energy-saving products, new working medium series environmental protection products, high-temperature pure water units, and stacking high.

Our services

Pre-Sales Service

*Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Free spare parts replacement within warranty period.

* Professional after-sales department to provide technical support, all complaints should be replied within 24 hours.

* Engineers available to service machinery overseas.

FAQ

Q1. Are you manufacturer or Trade Company?

A.We are professional factory, founded in 1998. OEM available!

Q2. What's the order process?

A.Inquiry---provide us all clear requirements.

Quotation---official quotation form with all detail specifications.

Contract confirmation---provide correct contract details.

Terms of payment--- By T/T 30% downpayment, balance before shipment.

Production---mass production

Testing---8hours, to ensure the quality of the machine

Shipping--- by sea, train. Detailed picture of package will be provided.

Q3.What terms of payment you use?

A.T/T, L/C, etc. Installation---install video/install manual

Q4. How to get a prompt quotation?

A.When you send the inquiry to us, please kindly send it with below technical information.

1). Application:

2). Cooling capacity: _____KW or _____ Kcal/hr or _____RT.

3). Outlet temperature:

4). Power supply: 3PH 380V/50HZ or 3PH 230V/60HZ or 3PH 440V/60HZ.

5). Location of your factory, we have to know the weather condition.

6). Any other special requirements: 5. Any technical support need or purchase need please contact to us!