"

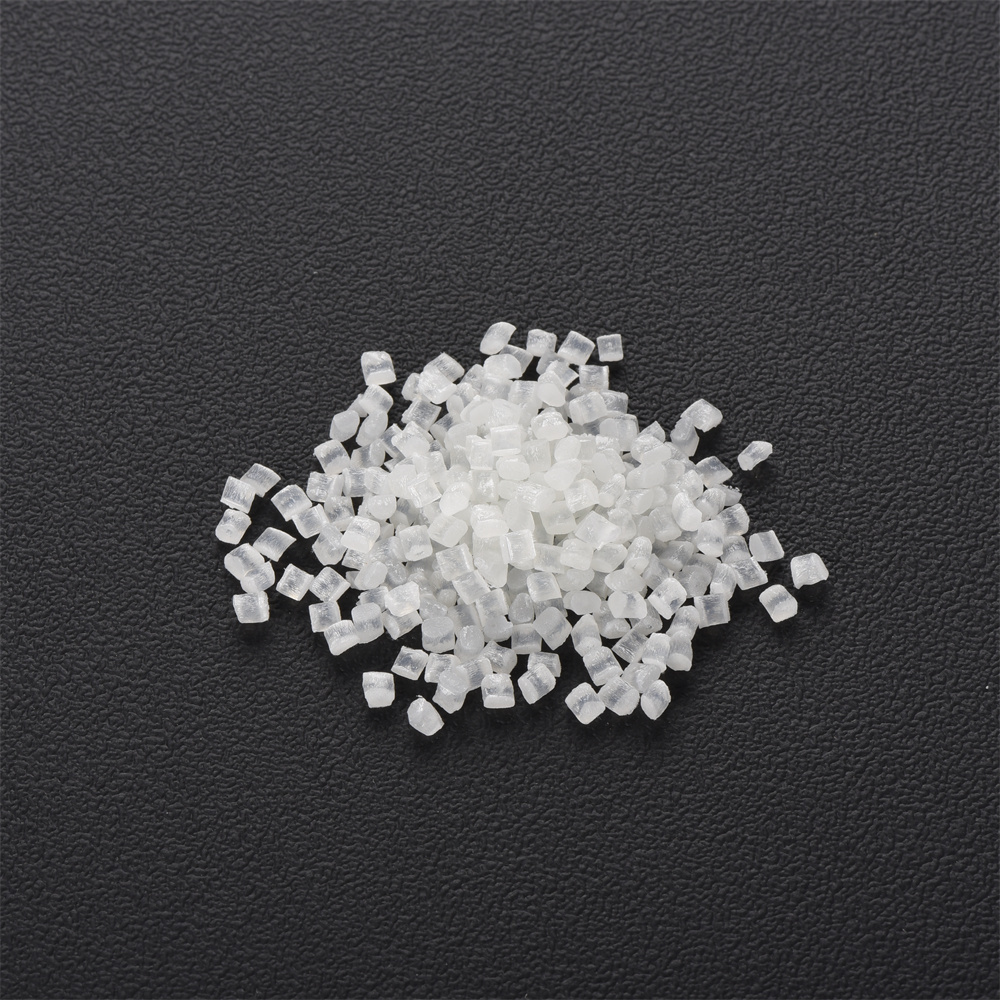

Polycarbonate

" is made of bisphenol A, which is a polymer material of polycarbonate. It has excellent high transparency and heat resistance temperature, as well as the highest impact strength of thermal plasticity resin, and good formability

"

Polycarbonate

" is the best material of choice for replacing metal supplies for automobile components, business machines, home appliances,electronic parts, food appliances, medical equipment and communication equipment.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Covestro/Makrolon

-

Material:

-

Polycarbonate PC Resin

-

Type:

-

Engineering Resin

-

Package:

-

25Kg/Bag

Quick Details

-

color:

-

Opaque

-

Shape:

-

Granules

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Covestro/Makrolon

-

Material:

-

Polycarbonate PC Resin

-

Type:

-

Engineering Resin

-

Package:

-

25Kg/Bag

Covestro Makrolon Polycarbonate

Place of Origin:China

Brand Name:Covestro/Makrolon

Model Number:9417

Featured:Flame retardant, Dimensionally stable, UV stable

Quality:High-quality

Application:General

Keywords:Covestro 9417/ Makrolon 9417/ Covestro Makrolon 9417

Material:Polycarbonate, 100% Vrigin PC Material

Brand:Covestro makrolon

Brand Name:Covestro/Makrolon

Model Number:9417

Featured:Flame retardant, Dimensionally stable, UV stable

Quality:High-quality

Application:General

Keywords:Covestro 9417/ Makrolon 9417/ Covestro Makrolon 9417

Material:Polycarbonate, 100% Vrigin PC Material

Brand:Covestro makrolon

Product Description

Makrolon® 9417

MVR (300 °C/1.2 kg) 6.0 cm³/10 min; 10 % glass fiber reinforced; flame retardant; UL 94V-0/1.5 mm and 5VA/3.0 mm; high viscosity; UV stabilized; easy release

MVR (300 °C/1.2 kg) 6.0 cm³/10 min; 10 % glass fiber reinforced; flame retardant; UL 94V-0/1.5 mm and 5VA/3.0 mm; high viscosity; UV stabilized; easy release

Rheological properties

|

Property

|

|

Test Condition

|

Unit

|

Standard

|

typical Value

|

|

|

C

|

Melt volume-flow rate

|

300 °C/ 1.2 kg

|

cm³/10 min

|

ISO 1133

|

6.0

|

|

|

|

Melt mass-flow rate

|

300 °C/ 1.2 kg

|

g/10 min

|

ISO 1133

|

7.0

|

|

|

C

|

Molding shrinkage, parallel

|

60x60x2 mm/ 500 bar

|

%

|

ISO 294-4

|

0.6

|

|

|

C

|

Molding shrinkage, normal

|

60x60x2 mm/ 500 bar

|

%

|

ISO 294-4

|

0.45

|

|

|

|

Molding shrinkage, parallel/normal

|

Value range based on general

practical experience |

%

|

b.o. ISO 2577

|

0.4-0.6

|

|

Mechanical properties (23 °C/50 % r. h.)

|

Property

|

|

Test Condition

|

Unit

|

Standard

|

typical Value

|

|

|

C

|

Tensile modulus

|

1 mm/min

|

MPa

|

ISO 527-1,-2

|

3800

|

|

|

|

Yield stress

|

50 mm/min

|

%

|

ISO 527-1,-2

|

64

|

|

|

|

Yield strain

|

50 mm/min

|

MPa

|

ISO 527-1,-2

|

4.6

|

|

|

C

|

Stress at break

|

50 mm/min

|

MPa

|

ISO 527-1,-2

|

45

|

|

|

C

|

Stress at break

|

50 mm/min

|

%

|

ISO 527-1,-2

|

15

|

|

|

C

|

Tensile creep modulus

|

1 h

|

MPa

|

ISO 899-1

|

3600

|

|

|

C

|

Tensile creep modulus

|

1000 h

|

MPa

|

ISO 899-1

|

2900

|

|

|

|

Flexural modulus

|

2 mm/min

|

MPa

|

ISO 178

|

3600

|

|

|

|

Flexural strength

|

2 mm/min

|

MPa

|

ISO 178

|

105

|

|

|

|

Flexural strain at flexural strength

|

2 mm/min

|

%

|

ISO 178

|

5.8

|

|

|

|

Flexural stress at 3.5 % strain

|

2 mm/min

|

MPa

|

ISO 178

|

95

|

|

|

C

|

Charpy impact strength

|

23 °C

|

kJ/m²

|

ISO 179/1eU

|

150C(N)

|

|

|

|

Charpy impact strength

|

-60 °C/3mm

|

kJ/m²

|

ISO 179/1eU

|

100C

|

|

|

|

Charpy notched impact strength

|

-30 °C/3mm

|

kJ/m²

|

ISO 21305/based on ISO 179/A

|

10C

|

|

|

|

Izod notched impact strength

|

23 °C/3mm

|

kJ/m²

|

ISO 21305/based on ISO 180/A

|

8C

|

|

|

C

|

Puncture impact properties - maximum force

|

23 °C

|

N

|

ISO 6603-2

|

4000

|

|

|

C

|

Puncture impact properties - maximum force

|

-30 °C

|

N

|

ISO 6603-2

|

3700

|

|

|

C

|

Puncture energy

|

23 °C

|

J

|

ISO 6603-2

|

25

|

|

|

C

|

Puncture energy

|

-30 °C

|

J

|

ISO 6603-2

|

15

|

|

|

|

Ball indentation hardness

|

|

N/mm²

|

ISO 2039-1

|

128

|

|

About

Polycarbonate

Hot Searches