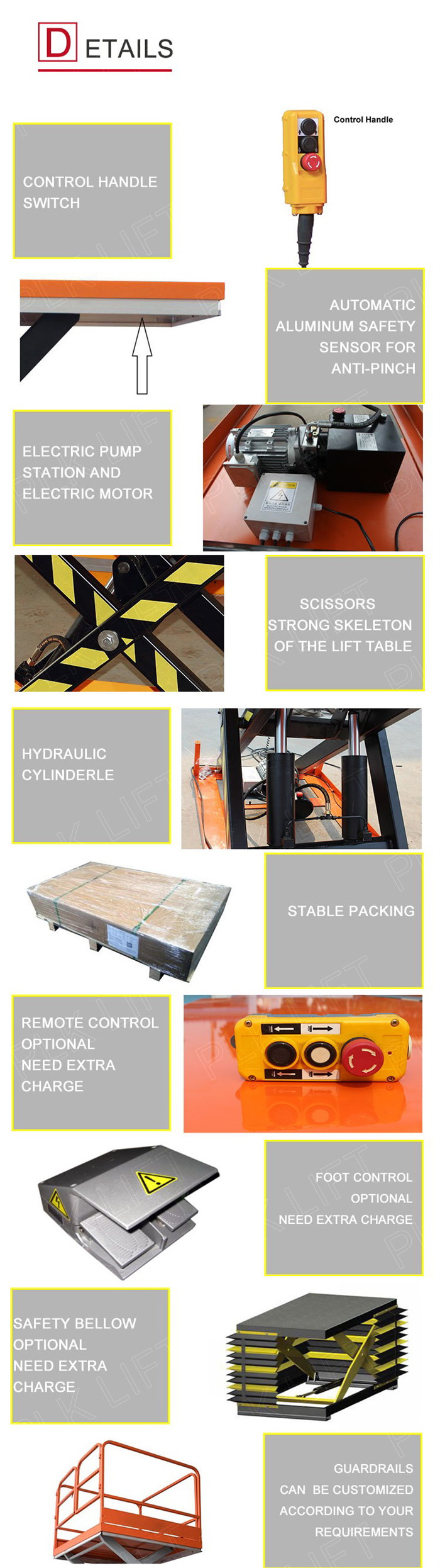

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

1.1kw,1.5kw,2.2kw

-

Min. Lifting Height:

-

205mm(one scissor)305mm(double)470mm(three)600mm(four)

-

Table Size:

-

customized

-

Overall Dimensions:

-

customized

-

Weight:

-

858 kg

-

Marketing Type:

-

Exclusive Quotes for 2021

-

Voltage:

-

Your Local Standard

-

Color:

-

As you Require

-

Type:

-

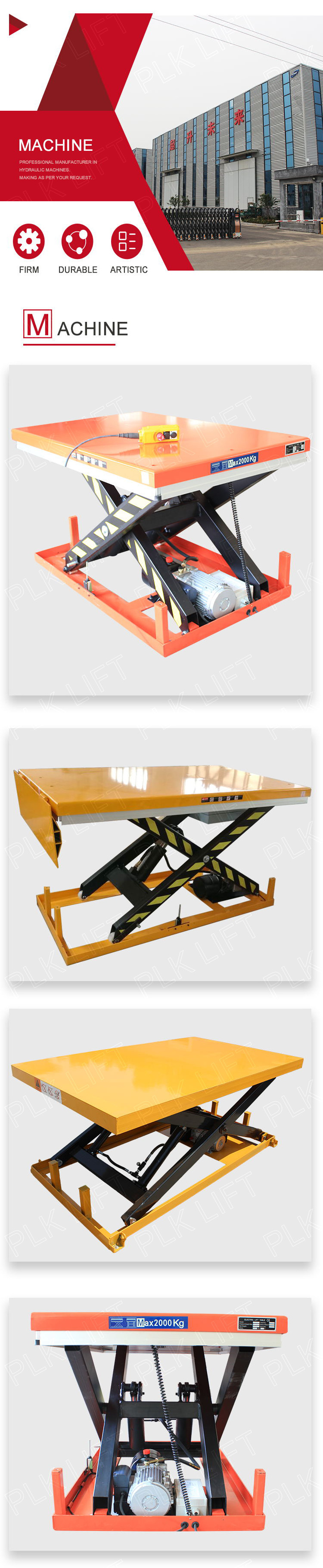

Scissor Hydraulic Lift Table

-

Application:

-

Jack Stuff from One Platform to Another

-

Material:

-

High-Duty Steel

-

Control Methods:

-

Control Panel or Remote (Latter Extra Charged)

-

After Warranty Service:

-

Free Parts Replacement

Quick Details

-

Warranty:

-

2 years

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

PLK LIFT

-

Power:

-

1.1kw,1.5kw,2.2kw

-

Min. Lifting Height:

-

205mm(one scissor)305mm(double)470mm(three)600mm(four)

-

Table Size:

-

customized

-

Overall Dimensions:

-

customized

-

Weight:

-

858 kg

-

Marketing Type:

-

Exclusive Quotes for 2021

-

Voltage:

-

Your Local Standard

-

Color:

-

As you Require

-

Type:

-

Scissor Hydraulic Lift Table

-

Application:

-

Jack Stuff from One Platform to Another

-

Material:

-

High-Duty Steel

-

Control Methods:

-

Control Panel or Remote (Latter Extra Charged)

-

After Warranty Service:

-

Free Parts Replacement

Single Scissor Arm Hydraulic Lift Table

Cheap and Customizable

- Prices are reduced to extremes with cheap labor costs, cheap electricity bills, relaxed macro economic policy in China. In foreign markets, many import countries give zero tariffs for our lift tables.

- Stationary Scissor Lift Tables feature various capacities, heights and platform sizes all based on customers' specific requirements.

- Customized units include tandem dual tables, tables with conveyor rollers, tables with wheels or tables with accordion bellows. Yet, we do have standard types as shown below, delivery of which is faster than customized ones.

Standard Conformity

Up to American ANSI/ASME and European EN1570 standards.

Safety Mechanisms Myriad

- 1. Explosion-proof valves : protect hydraulic pipe, anti hydraulic pipe rupture.

- 2. Spillover valve : It can prevent high pressure when the machine moves up, adjusting the pressure.

- 3. Emergency decline valve: it can go down when you meet an emergency or the power is off.

- 4. Overload protection locking device: in case of dangerous overload.

- 5. Anti-dropping device: Prevent fall of platform.

- 6. Automatic aluminum safety sensor : lift platform will stop automatically when coming across barriers.

Tested and Tried by Global Clients

Our lift talbes have been exprorted to all countries around the globe for many years, and no quality complaints have ever been reported yet.

After Sales Service

1)

One year Free Parts Replacement Policy

whereby any non-human caused mechanical or structural failure qualifies for parts replacement free of charge. Parts include but not limited to pumps, engines, cylinders.

2)

Life Technical Support

via video link or email, bilingual team 24/7 on standby.

|

Model |

Load Capacity(KG) |

Self Height |

Max Platform Height(MM) |

Platform Size(MM) |

Lifting time |

Net weight |

|

(MM) |

(S) |

(KG) |

||||

|

HW1001 |

1000 |

205 |

1000 |

1300×820 |

20~25 |

160 |

|

HW1002 |

1000 |

205 |

1000 |

1600×1000 |

20~25 |

186 |

|

HW1003 |

1000 |

240 |

1300 |

1700×850 |

30~35 |

200 |

|

HW1004 |

1000 |

240 |

1300 |

1700×1000 |

30~35 |

210 |

|

HW1005 |

1000 |

240 |

1300 |

2000×850 |

30~35 |

212 |

|

HW1006 |

1000 |

240 |

1300 |

2000×1000 |

30~35 |

223 |

|

HW1007 |

1000 |

240 |

1300 |

1700×1500 |

30~35 |

365 |

|

HW1008 |

1000 |

240 |

1300 |

2000×1700 |

30~35 |

430 |

|

HW2001 |

2000 |

230 |

1000 |

1300×850 |

20~25 |

235 |

|

HW2002 |

2000 |

230 |

1050 |

1600×1000 |

20~25 |

268 |

|

HW2003 |

2000 |

250 |

1300 |

1700×850 |

25~35 |

289 |

|

HW2004 |

2000 |

250 |

1300 |

1700×1000 |

25~35 |

300 |

|

HW2005 |

2000 |

250 |

1300 |

2000×850 |

25~35 |

300 |

|

HW2006 |

2000 |

250 |

1300 |

2000×1000 |

25~35 |

315 |

|

HW2007 |

2000 |

250 |

1400 |

1700×1500 |

25~35 |

415 |

|

HW2008 |

2000 |

250 |

1400 |

2000×1800 |

25~35 |

500 |

|

HW4001 |

4000 |

240 |

1050 |

1700×1200 |

30~40 |

375 |

|

HW4002 |

4000 |

240 |

1050 |

2000×1200 |

30~40 |

405 |

|

HW4003 |

4000 |

300 |

1400 |

2000×1000 |

35~40 |

470 |

|

HW4004 |

4000 |

300 |

1400 |

2000×1200 |

35~40 |

490 |

|

HW4005 |

4000 |

300 |

1400 |

2200×1000 |

35~40 |

480 |

|

HW4006 |

4000 |

300 |

1400 |

2200×1200 |

35~40 |

505 |

|

HW4007 |

4000 |

350 |

1300 |

1700×1500 |

35~40 |

570 |

|

HW4008 |

4000 |

350 |

1300 |

2200×1800 |

35~40 |

655 |

|

HD1000 |

1000 |

305 |

1780 |

1300X820 |

35-45 |

210 |

|

HD2000 |

2000 |

350 |

1780 |

1300X850 |

35-45 |

295 |

|

HD4000 |

4000 |

400 |

2050 |

1700X1200 |

55-65 |

520 |

|

HT1000 |

1000 |

470 |

3000 |

1700x1000 |

35-45 |

450 |

|

HT2000 |

2000 |

560 |

3000 |

1700x1000 |

50-60 |

750 |

|

HF400 |

400 |

600 |

4140 |

1700x1000 |

30-40 |

800 |

|

HF800 |

800 |

706 |

4210 |

1700x1000 |

70-80 |

858 |

|

HF2000 |

2000 |

850 |

4200 |

2500*1500 |

70-80 |

900 |

|

Model |

Load Capacity(KG) |

Self Height |

Max Platform Height(MM) |

Platform Size(MM) |

Lifting time |

Net weight |

|

(MM) |

(S) |

(KG) |

||||

|

HW501L |

500 |

200 |

1000 |

1200*600 |

20~25 |

120 |

|

HW502L |

500 |

200 |

1000 |

1200*800 |

20~25 |

130 |

|

HW500L |

500 |

200 |

1000 |

2000*800 |

20~25 |

240 |

|

HD2000L |

2000 |

205 |

1000 |

2500*820 |

20~25 |

300 |

|

HD4000L |

4000 |

230 |

1000 |

2500*850 |

20~25 |

320 |

|

HD8000L |

8000 |

240 |

1050 |

3000*1200 |

20~25 |

370 |

|

HW1001Z |

1000 |

180 |

770 |

610*916 |

15~20 |

115 |

|

HW0501Z |

500 |

180 |

950 |

610*916 |

17~22 |

160 |

|

HW1000I |

1000 |

190 |

1010 |

1300*800 |

20~25 |

160 |

|

HW2000I |

2000 |

190 |

1010 |

1300*800 |

20~25 |

235 |

|

HW3000I |

3000 |

220 |

1010 |

1300*800 |

20~25 |

350 |

Click Here to Get Latest Quote...

1. Surface treatment: shot blasting and stoving varnish with anti-corrosion function.

2. High quality pump station makes scissor lift table lift and fall very stably.

3. all scissors pivot points adopt hardened pins that operate in lubricated-for-life, virtually

maintenance-free bushings .

4. Removable lifting eye to help lift the table and install.

5. Heavy duty cylinders with drainage system and check valve to stop the lift table dropping in case of hose burst.

6. Pressure relief valve prevents overload operation; Flow control valve makes descending speed adjustable.

7. Equipped with aluminum anti-pinch safety sensor underneath the platform while descending.

8. Up to American standard ANSI/ASME and European standard EN1570

9. Safe clearance between scissors to prevent wear and tear during operation.

10. Simple structure makes it much easier to operate and maintain .

13. Stops at the accurate position .

Safety Precautions:

1. Explosion-proof valves : protect hydraulic pipe, anti hydraulic pipe rupture.

2. Spillover valve : It can prevent high pressure when the machine moves up, adjusting the pressure.

3. Emergency decline valve: it can go down when you meet an emergency or the power is off.

4. Overload protection locking device: in case of dangerous overload.

5. Anti-dropping device: Prevent falling of platform.

6. Automatic aluminum safety sensor : lift platform will stop automatically when coming across barriers.