- Product Details

- {{item.text}}

Quick Details

-

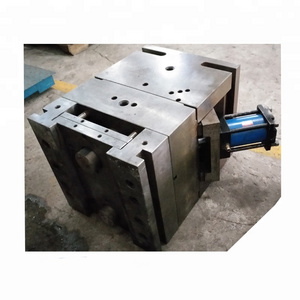

Mold type:

-

die casting mold

-

Mould material:

-

H13,2344,8407,8418,SKD61,DAC,FDAC

-

Mould base:

-

LKM.HASCO, DME...

-

Runner:

-

Hot Runner\ Cold Runner

-

Mould life:

-

100000-800000 shots

-

Surface treatment:

-

Polish. Etched. Texture

-

Cavity:

-

Multi or Single Cavity

-

certification:

-

ISO 9001:2015

-

Shape:

-

die casting

-

type:

-

100% direct factory

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

zs

-

Model Number:

-

custom

-

Mold type:

-

die casting mold

-

Mould material:

-

H13,2344,8407,8418,SKD61,DAC,FDAC

-

Mould base:

-

LKM.HASCO, DME...

-

Runner:

-

Hot Runner\ Cold Runner

-

Mould life:

-

100000-800000 shots

-

Surface treatment:

-

Polish. Etched. Texture

-

Cavity:

-

Multi or Single Cavity

-

certification:

-

ISO 9001:2015

-

Shape:

-

die casting

-

type:

-

100% direct factory

Product Details

|

Item

|

|

Description

|

|

Die Casting Mold

|

Type

|

Single cavity molds / Multi cavity molds / Family molds; Two or three plate molds is available

|

|

|

Mold Material

|

SKD61, H13, DIEVAR, QDN, 840, 2344V, TQ1, 2343, 45#Steel etc.

|

|

|

Dimension

|

According to the drawing or sample

|

|

|

Product Process

|

Polish/sand blast/EDM/Milling/Texture/Grind/Pre treatment/Quenching/Lathe/Wire Cut/Annealing/Temper etc.

|

|

Die Casting Machine

|

Machines

|

125T-2500T die casting machine, Milling machine/EDM/EDM wire cut machine/Die casting machine/CNC machine/grinding

machine/Drilling machine/Lathe machine etc. |

|

Product

|

|

ADC12/ADC10/A360/A380/A356/Zinc 1#/ Zinc 2# /Zamak3/ZL102/YL104/YL112/YL113/Alsi12Fe/AlSi9cu3, etc.

|

|

|

Design Software

|

CAD, UG, Pro/E, Solid works

|

|

|

Certification

|

ISO 9001:2015, ROHS

|

|

|

Application

|

Precision metal parts and components / Renewable Energy ! Consumer Electrical Components / Photovoltaic Moudle /

lndustrial components / Telecommunications / Automotive / Lighting components / Furniturec omponents, etc. |

|

|

Surface Treatment

|

Powder coating/Plated/Anodize/Painting/Chrome plating/Sandblasting/Nickel plated/Chromat conversion

coasted/electroplate/Galvanized etc. |

Products Show

About Us

Our Service

1. 3D Printing

3D printing is suitable for low volume production and used to test product appearance and structure. Suitable for plastic and metal materials.

2. Mold Design

15+experienced engineering design team, able to design and manufacture according to customer requirements, to ensure that the produced accessories meet customer requirements.

3. CNC Machining

CNC machine tools can complete the processing of various shapes, sizes and materials, which can ensure the consistency and stability of the processed products.

4. Die Casting

We offer various high quality metal die casting process services including aluminum die casting, zinc die casting, and magnesium die casting.

5. Surface Finishing

We also provide surface treatment services for die casting products, such as anodizing, powder coating, electroplating, etc.

6. Assembly & Package

We have our own assembly line to help customers assemble products, customize product packaging, etc., to meet all customized requirements of customers.

Die Casting Process

Industry We Served

Alpine mold

has completed

5000+

die-casting projects to solve project problems for different industries and provide high quality products, such as

security

,

automotive engines

,

hardware and bathroom

,

medical

,

electronics

,

lighting

,

energy storage

and so on.

Factory Show

FAQs

Q1: ARE YOU A FACTORY OR TRADE COMPANY?

A: Yes, we are a factory, is a one-stop source for all of your customized products.

Q2:

What do I need for offering a quote?

A: Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and other technical requirement, etc.), quantity, application or samples. Then we will quote the best price within 24h.

A: Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and other technical requirement, etc.), quantity, application or samples. Then we will quote the best price within 24h.

Q3:

What materials can be used for die casting?

A:

Common materials include aluminum alloy, zinc alloy, magnesium alloy, etc. These materials have the advantages of high stability, light weight, and corrosion resistance.

Q4:

How to choose a die casting factory that suits your needs?

A: You need to consider multiple factors such as good manufacturing capacity, management level, customer service and quality assurance, as well as the price and delivery time that meet your needs.

Q5:

What are the methods of die casting?

A: Generally, it can be divided into cold chamber die-casting, hot chamber die-casting, semi-hot chamber die-casting and other methods.

Q6:

Is it possible to know how are my products going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Hot Searches