- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

customized

-

Weight:

-

11000 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

customized

-

KEYWORD:

-

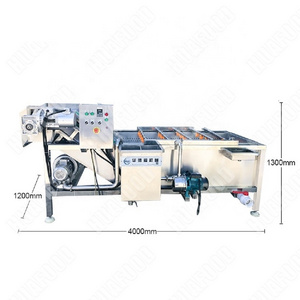

Vegetable Fruits Cleaning Washing Line

-

Material:

-

SS304

-

Capacity:

-

500-3000kg/h

-

Feature:

-

High Efficiency Easy Operate

-

type:

-

Vegetable Processing Machine

-

name:

-

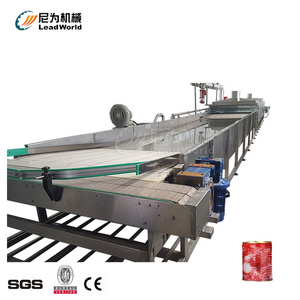

Multifunctional Fruit production line

-

usage:

-

Food Industry Equipment

-

Application:

-

canned mushrrom

-

Finished Products:

-

canned food

Quick Details

-

Machinery Capacity:

-

1~60 Tons

-

Brand Name:

-

Genyond

-

Year:

-

2023

-

Dimension(L*W*H):

-

customized

-

Weight:

-

11000 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

customized

-

KEYWORD:

-

Vegetable Fruits Cleaning Washing Line

-

Material:

-

SS304

-

Capacity:

-

500-3000kg/h

-

Feature:

-

High Efficiency Easy Operate

-

type:

-

Vegetable Processing Machine

-

name:

-

Multifunctional Fruit production line

-

usage:

-

Food Industry Equipment

-

Application:

-

canned mushrrom

-

Finished Products:

-

canned food

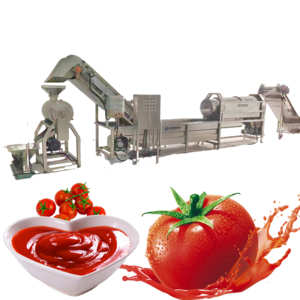

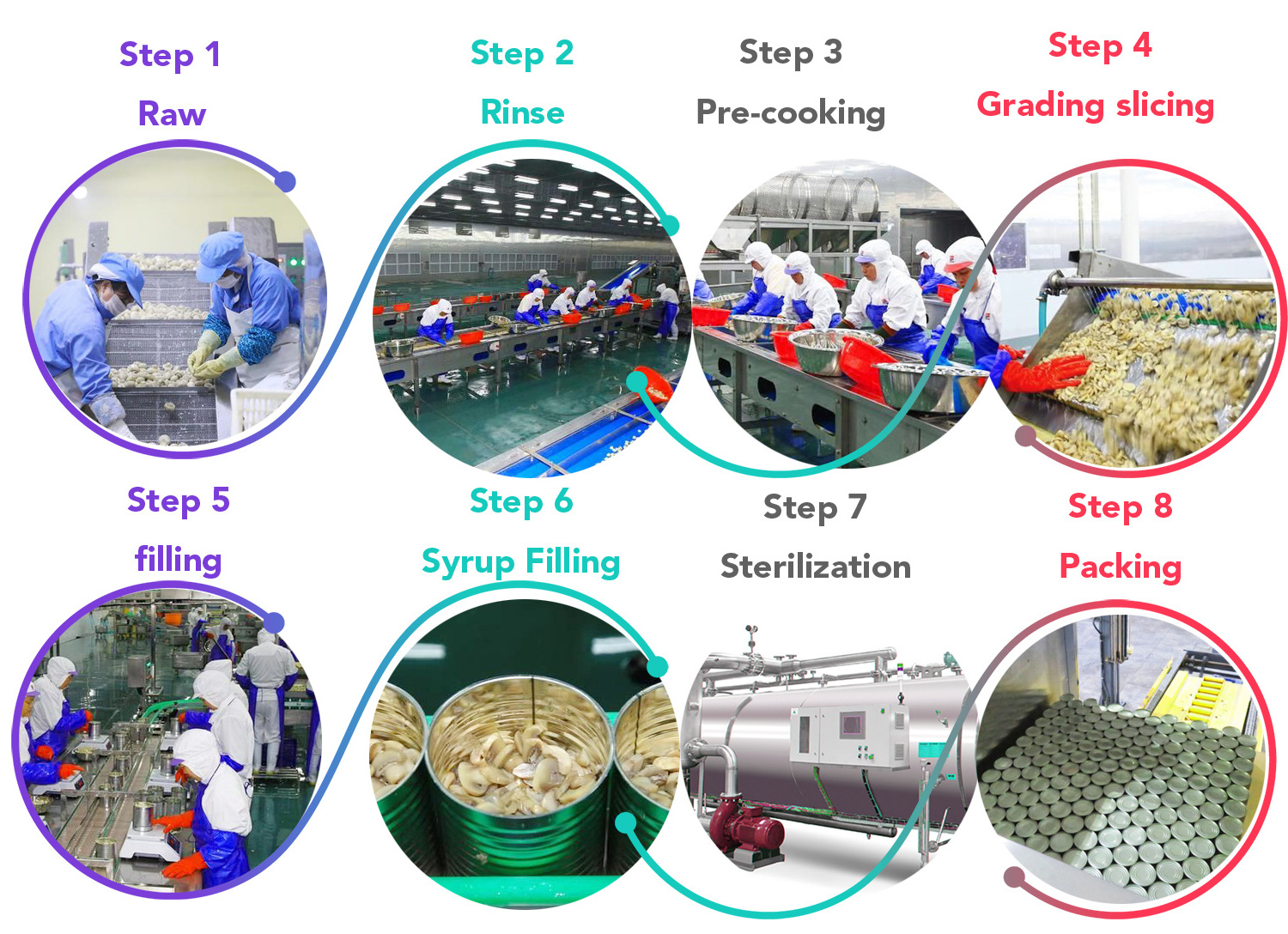

(1) Acceptance of raw mushrooms:

Fresh mushrooms processed for export of canned mushrooms must be first-class mushrooms; second- and third-level mushrooms can be processed for general canning. As a raw material for canned sheet mushrooms, the cap diameter should not exceed 4.5 cm, and as a raw material for canned mushrooms, the cap diameter should not exceed 6.0 cm.

canned mushroom factory

(2) Rinse:

Pour different grades of fresh mushrooms into 0.03% sodium metabisulfite solution, and gently flip up and down to wash away the sand, impurities, wax and lipids on the surface of the mushroom. After rinsing for 2 minutes, remove it and put it in running water for washing.

champion mushroom

(3) Pre-cooking:

First boil the prepared 0.1% citric acid solution in the pre-boiler, and then put the rinsed mushrooms, the ratio of water to mushrooms is about 3: 2. Continue to boil until cooked through, 8-10 minutes in total, then quickly cool.

(4)Grading and slicing

Classification according to the specifications of canned mushrooms. Approximately 1.5cm in diameter is a grade mushroom; about 2.5cm in diameter is a second grade mushroom; about 3.5cm in diameter is a third grade mushroom; less than 4.5cm is used to process sliced mushrooms, large mushrooms and off-handled mushrooms with a diameter of more than 4.5cm It can be used for processing pieces mushrooms.

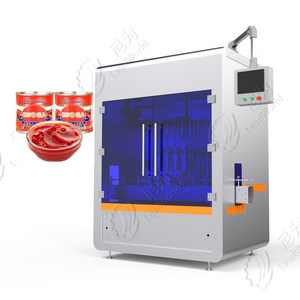

(5) Filling:

Tin cans or glass bottles should be strictly inspected before being filled, and unqualified empty cans should be removed. Then wash it in hot water at 90 ~ 95 ℃, put it on a clean shelf and drain it for use.

(6) Add soup:

The soup formula is 2.3% to 2.5% refined salt and 0.05% citric acid. When adding soup, the soup temperature should be above 80 ℃.

(7) Pre-sealing, venting and sealing:

Exhaust in time after pre-sealing. When heating the exhaust gas, the exhaust temperature of 3000g canning is 85 ~ 90 ℃, 17min; the exhaust temperature of 284g canning is 85 ~ 90 ℃, 7min. If it is sealed with vacuum exhaust, the vacuum degree is 3432 ~ 3922Pa.

champion mushroom wholesale

(8) Sterilization and cooling:

Cans after venting and sealing should be sterilized immediately. After sterilization, back pressure cooling is performed.

(9)Inspection and packaging,then shipping

| Filling heads | 2/4/6/8/10/12 |

| capacity | 600-5000 cans/H |

| Filling volume | 10 ml- 5000 ml |

| Air consumption | 120 L/min-300 L/min |

| Power | 1-3 KW |

Cans Sealing Machine

| Capacity | 30-100 cans/min |

| Can size | D:50-400 mm H: 50-350 mm |

| Power | 1-3 KW |

Turnkey solution with after packing work flow:

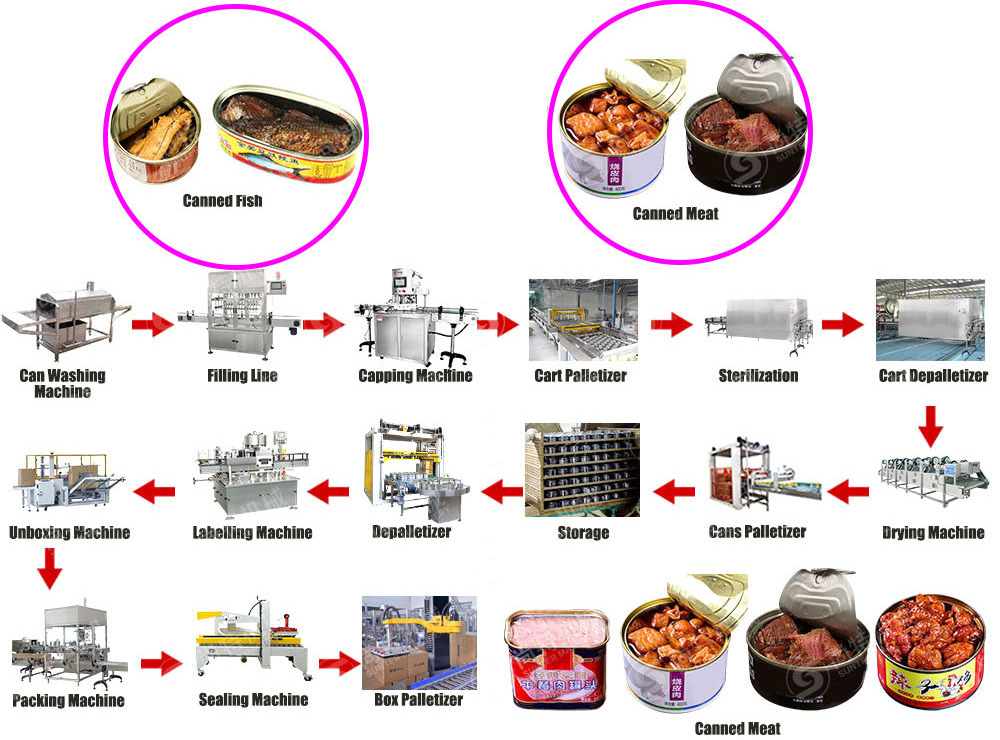

canned fish Production Line

Canned meat Production Line

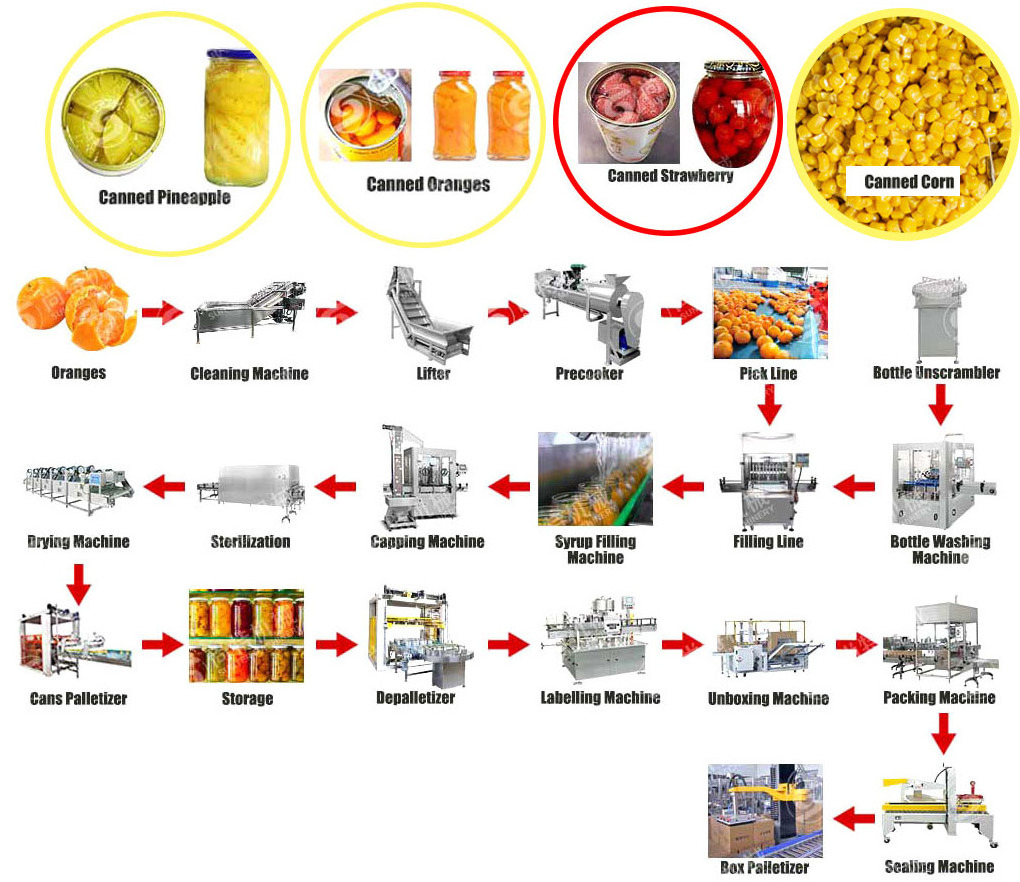

Canned Orange Production Line

Canned Pineapple Production Line

Strawberry Canned Production Line

Canned Corn Production Line

Canned Yellow Peach Production Line

Canned cucmber Production Line

Canned Mushroom Production Line