- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

4760*1900*4700MM

-

Power (kW):

-

11

-

Weight (KG):

-

4500 KG

-

Product Name:

-

EPS Polystyrene Shape Moulding Molding Thermocol Forming Machine

-

Certification:

-

CE

-

Raw material:

-

Expanded Polystyrene(EPS)

-

Finished products:

-

EPS Ice Vegetable Fish Box Underfloor Heating Panel

-

Feature:

-

Full Automatic/Running Stable/Energy Saving

-

Advantage:

-

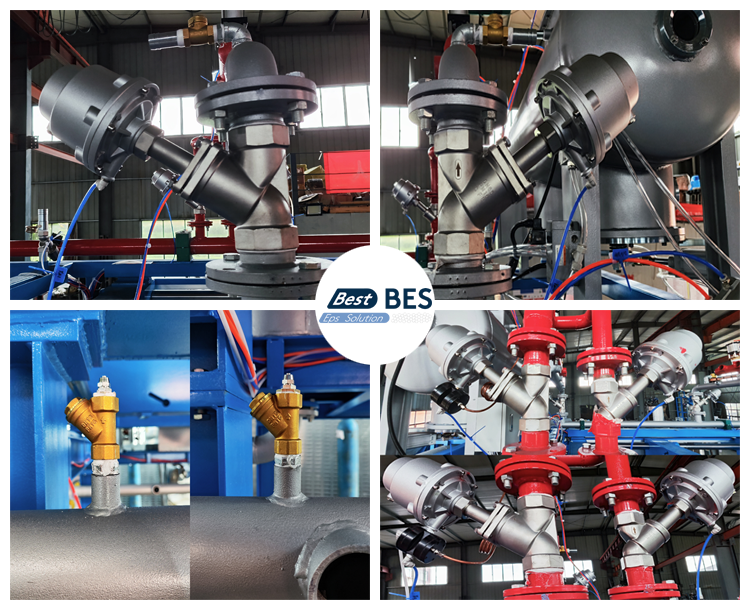

High Technology&Quality/Famous Brand of Components

-

Driven model:

-

Hydraulic System

-

HS code:

-

84778000

-

Control system:

-

PLC+Touch Panel

-

Local Service Location:

-

Vietnam/Middle East/Turkey

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Bes

-

Machine Type:

-

Typical and Economical

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

4760*1900*4700MM

-

Power (kW):

-

11

-

Weight (KG):

-

4500 KG

-

Product Name:

-

EPS Polystyrene Shape Moulding Molding Thermocol Forming Machine

-

Certification:

-

CE

-

Raw material:

-

Expanded Polystyrene(EPS)

-

Finished products:

-

EPS Ice Vegetable Fish Box Underfloor Heating Panel

-

Feature:

-

Full Automatic/Running Stable/Energy Saving

-

Advantage:

-

High Technology&Quality/Famous Brand of Components

-

Driven model:

-

Hydraulic System

-

HS code:

-

84778000

-

Control system:

-

PLC+Touch Panel

-

Local Service Location:

-

Vietnam/Middle East/Turkey

Product Description

|

Technical Data

|

|

|

|

|

|

|||||

|

Item

|

Unit

|

BES-PZT-1400

|

BES-PZT-1600

|

BES-PZT-1750

|

BES-PZT-1800

|

|||||

|

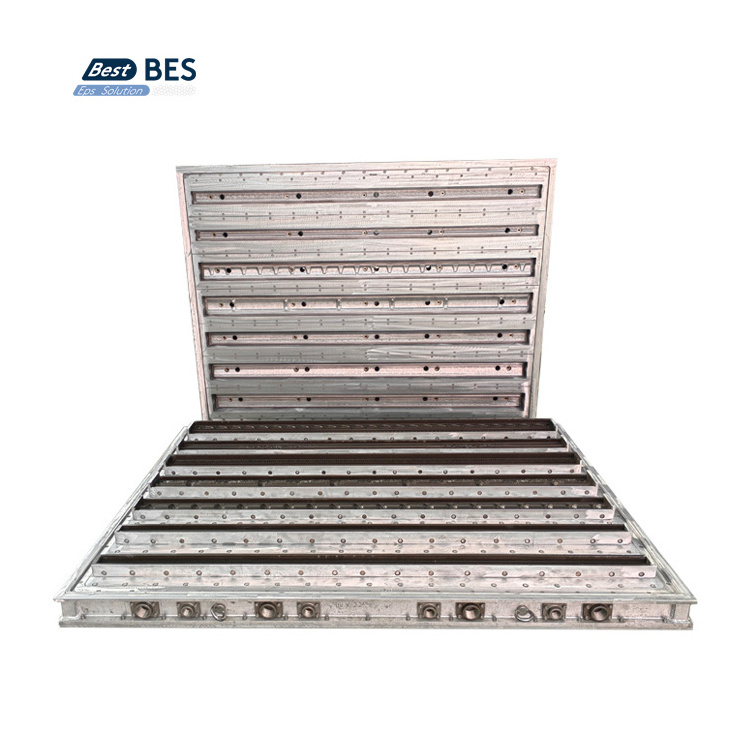

Mould Dimension

|

mm

|

1400×1200

|

1600×1350

|

1750×1500

|

1800×1600

|

|||||

|

Max Product Dimension

|

mm

|

1200×1000×350

|

1400×1100×350

|

1550×1300×350

|

1610×1400×350

|

|||||

|

Rear Window Size

|

mm

|

1300×1080

|

1450×1150

|

1600×1350

|

1680×1440

|

|||||

|

Stroke

|

mm

|

270-1420

|

270-1420

|

270-1420

|

220-1370

|

|||||

|

Steam Entry

|

mm

|

DN100

|

DN100

|

DN100

|

DN100

|

|||||

|

Steam Consumption

|

t/t

|

(10-13T) steam consumption for 1T EPS raw material

|

|

|

|

|||||

|

Water Entry

|

mm

|

DN80

|

DN80

|

DN80

|

DN80

|

|||||

|

Cooling Water Consumption

|

kgs/cycle

|

50-150

|

55-180

|

60-190

|

80-200

|

|||||

|

Compressed Air Entry

|

mm

|

DN65

|

DN65

|

DN65

|

DN65

|

|||||

|

Compressed Air Consumption

|

m3/cycle

|

1.8

|

2

|

2

|

2.2

|

|||||

|

Vacuum Pump Capacity

|

m3/h

|

230

|

280

|

280

|

280

|

|||||

|

Connected Load

|

kw

|

15.2

|

17.2

|

17.2

|

20.7

|

|||||

|

Overall Dimension

|

mm

|

4920×2250×4660

|

5220×2680×4690

|

5220×2680×4790

|

5220×2760×5120

|

|||||

|

Machine Weight

|

kg

|

5700

|

7000

|

7500

|

8000

|

|||||

|

Cycle Time

|

s

|

60-150

|

90-160

|

90-160

|

120-190

|

|||||

|

Other Specifications Can Also Be Customized As Per Client's Requirements

|

|

|

|

|

|

|||||

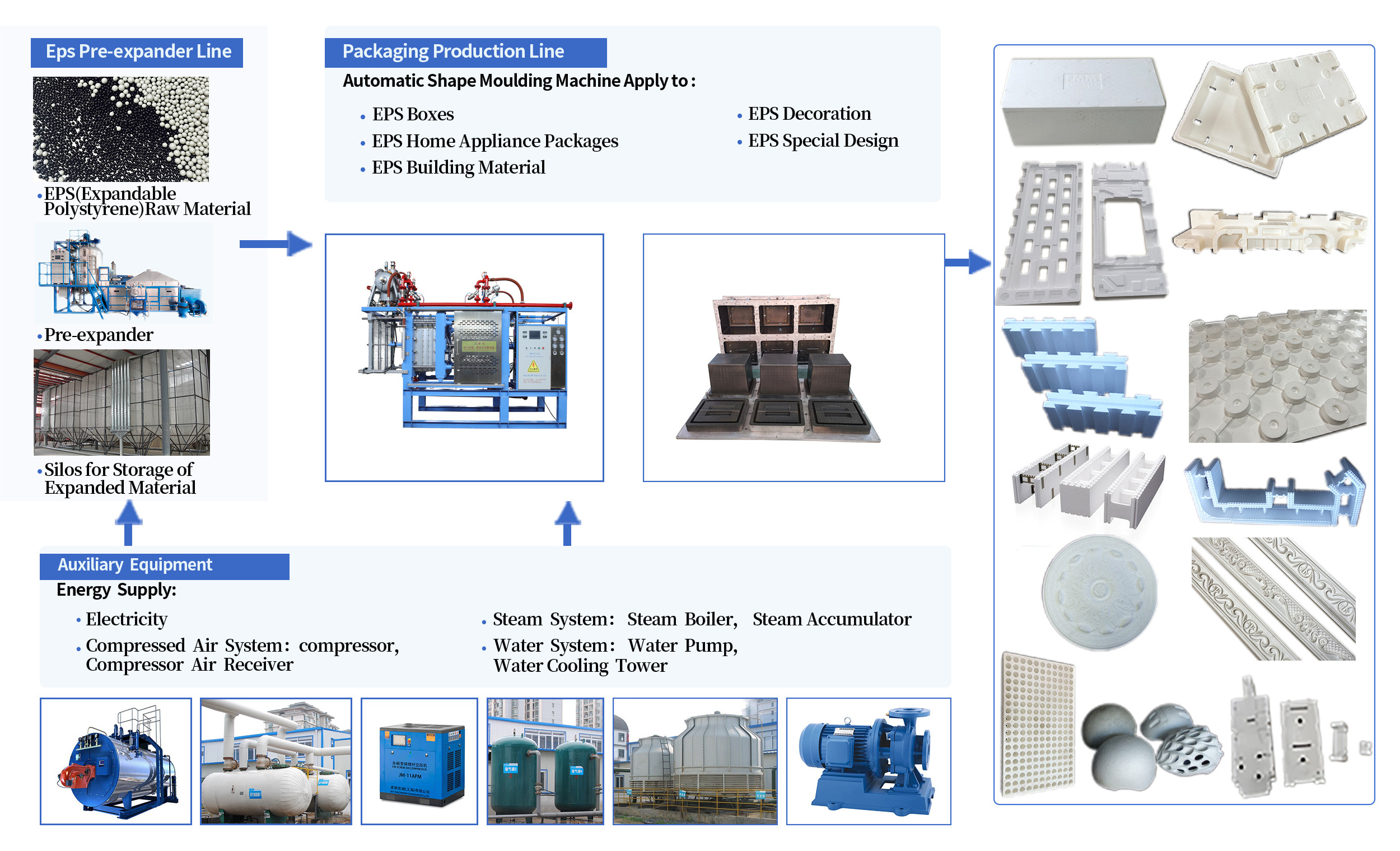

EPS Expandable Polystyrene Shape Moulding Molding Thermocol Forming Machine for Ice Vegetable Fish Box Underfloor Heating Panel

1. This machine applies PLC and touch screen,advanced moulding technique and can produce various shapes of EPS

products.

2. This machine can provide different kinds of foam articles with lower moisture content, high foaming speed and lower

consumption of energy.

3. There are four kinds of operating mode (automatic,semi-automatic,pause-startup and manual operation)with safe-guard

protective device to ensure safe operation.

4. This machine has microcomputer control and touch screen display. It can function high efficiently under computer c

ontrol and management with high automation.Simplicity of operation and easy to maintain,it can reduce the labor

intensity.

5. This machine applies advanced electrical and hydraulic integration system,which improves the moulding speed,lowers

t

he energy consumption remarkably and reduces the environmental pollution.

6. Mechanic de-mould mode.

Highlights Of Machines

Hot Searches