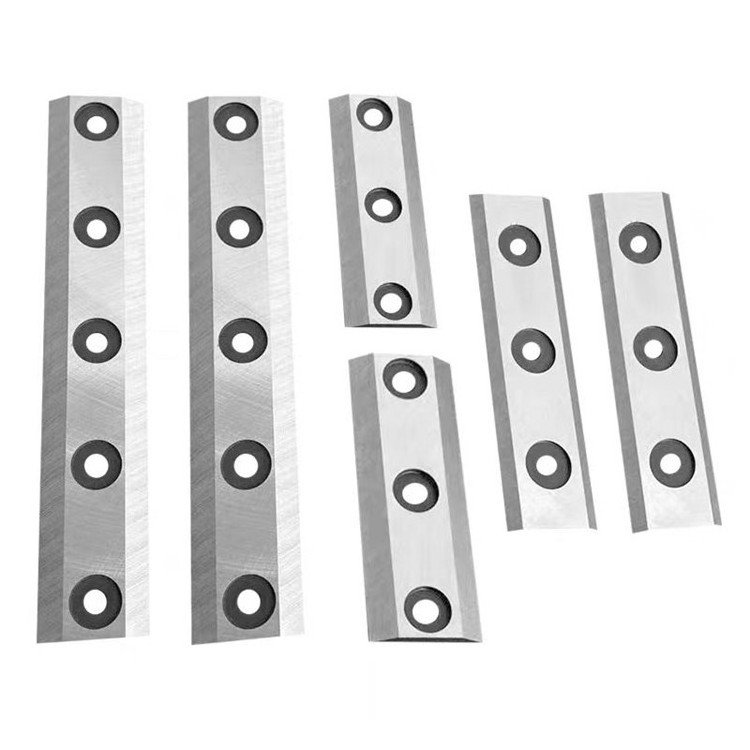

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1 KG

-

Product name:

-

woodworking tools

-

Material:

-

Alloy tool steel D2 1.2379 HSS SKD11 A8 9CrSi

-

Application:

-

Wood working industrial

-

Advantage:

-

High Performance

-

Package:

-

Wood Box

-

MOQ:

-

5pcs

-

Hardness:

-

58 - 63 HRC

-

Certificate:

-

CE

-

Shipping Method:

-

Air/Sea Shipping, or Courier

-

OEM Service:

-

Support

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Marketing Type:

-

Hot Product 2024

-

Brand Name:

-

HX

-

Weight (KG):

-

1 KG

-

Product name:

-

woodworking tools

-

Material:

-

Alloy tool steel D2 1.2379 HSS SKD11 A8 9CrSi

-

Application:

-

Wood working industrial

-

Advantage:

-

High Performance

-

Package:

-

Wood Box

-

MOQ:

-

5pcs

-

Hardness:

-

58 - 63 HRC

-

Certificate:

-

CE

-

Shipping Method:

-

Air/Sea Shipping, or Courier

-

OEM Service:

-

Support

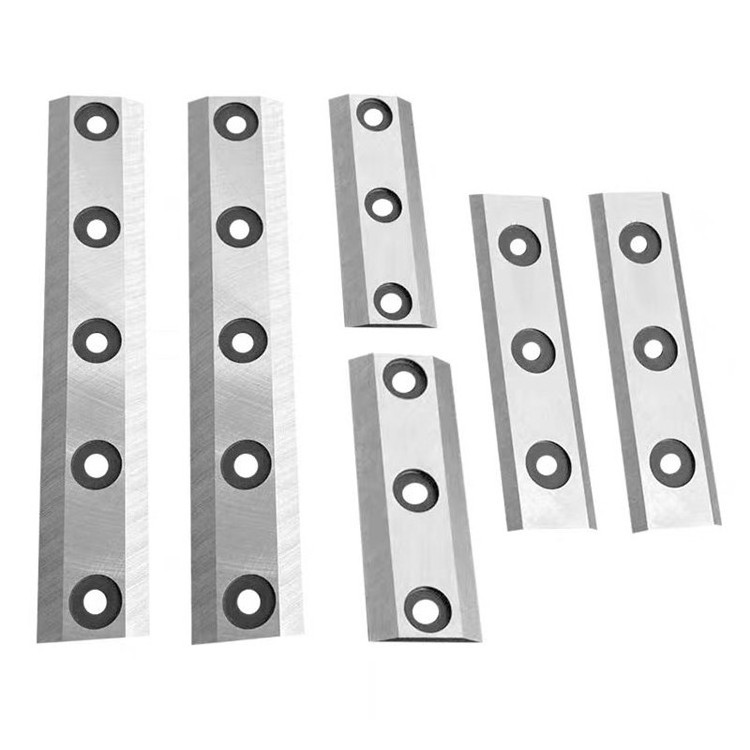

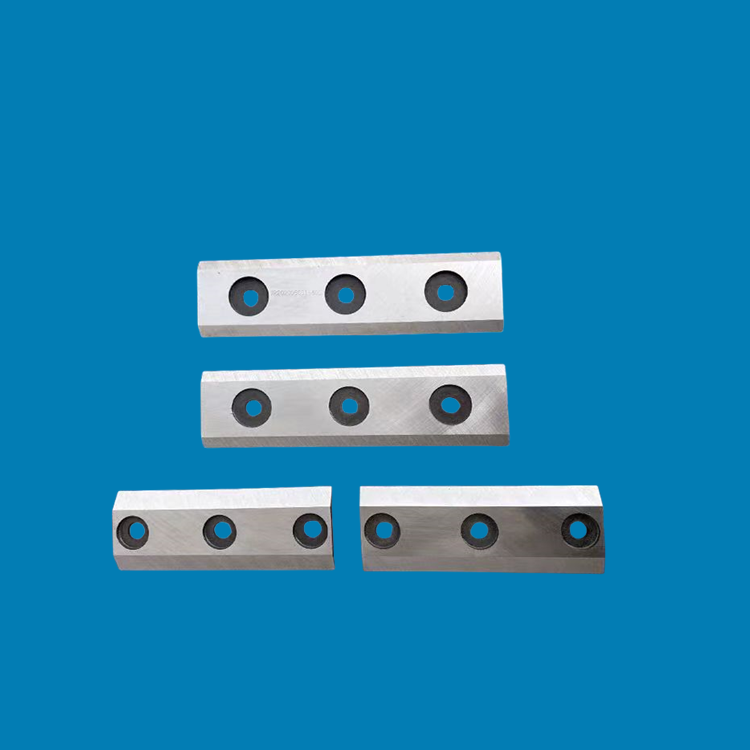

Products Description

Hanxin's knives are manufactured from high quality steel. All knives delivered to customers are not only sharp without burrs, but also last longer sharpness with the unique heat treatment.

We have different materials to choose from. You can tell me which type of wood you need to handle, and I will recommend the most suitable material for you

Details Images

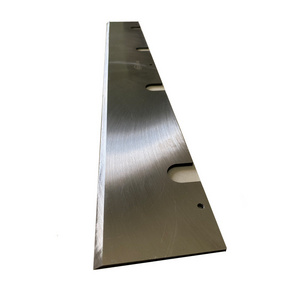

|

Material

|

A8b, H12

|

Forged steel plate

|

Imported special steel plates

|

H13

|

H12

|

A8b

|

|||||

|

Hardness

|

58-62HRC

|

55-56

|

56-58

|

58-60

|

58-60

|

60-62

|

|||||

|

Application

|

Fresh trees, dry trees, dry leaves,straws

|

|

|

|

|

|

|||||

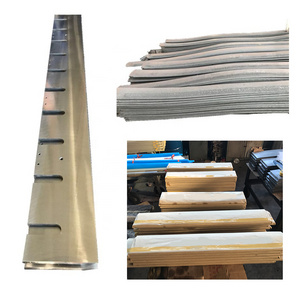

Heat temperature , repeated forging at 3000

°C

After thousands of rounds of hammering and forming, the forged blade material has high hardness, toughness, wear resistance, good texture, and corrosion resistance, ensuring that the blade has good wear resistance and a long service life.

Product packaging

Certifications

FAQ

1. Are you manufacturer of trading company?

We are a factory with 20 years of experience in blade production.

2. What data do I need to provide for you to produce blades?

The first choice is to provide drawings, which is the most accurate. Of course, if there are no drawings, you can measure the length, width, and thickness of your existing blades.

5. How do I pay to you?

(1) 30% deposit of the total amount to be paid by T / T in advance, the balance of 70%will be paid before the goods leave the factory.

(2) Alibaba platform credit insurance payment

6. How long is the lead time?

For standard size, that would be 2-3 working days;

We are a factory with 20 years of experience in blade production.

2. What data do I need to provide for you to produce blades?

The first choice is to provide drawings, which is the most accurate. Of course, if there are no drawings, you can measure the length, width, and thickness of your existing blades.

5. How do I pay to you?

(1) 30% deposit of the total amount to be paid by T / T in advance, the balance of 70%will be paid before the goods leave the factory.

(2) Alibaba platform credit insurance payment

(3)We can negotiate specific payment terms with our client.

6. How long is the lead time?

For standard size, that would be 2-3 working days;

For non-standard sizes and need to be customized , it would be about 15-25 working days.

Hot Searches