- Product Details

- {{item.text}}

Quick Details

-

Power:

-

max. 22.5kW

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Cooldo

-

Model Number:

-

NCH/NCN Series

-

Dimension(L*W*H):

-

depends on your kind option

-

Weight:

-

depends on your kind option

-

Warranty:

-

18 Months

-

Certification:

-

ISO9001:2008

-

Water flow:

-

5~300t/h

-

Production time:

-

Typically 3~5 weeks

Quick Details

-

Cooling Type:

-

Cross Flow

-

Material:

-

Superdyma

-

Voltage:

-

three phases, 380~480v, AC

-

Power:

-

max. 22.5kW

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Cooldo

-

Model Number:

-

NCH/NCN Series

-

Dimension(L*W*H):

-

depends on your kind option

-

Weight:

-

depends on your kind option

-

Warranty:

-

18 Months

-

Certification:

-

ISO9001:2008

-

Water flow:

-

5~300t/h

-

Production time:

-

Typically 3~5 weeks

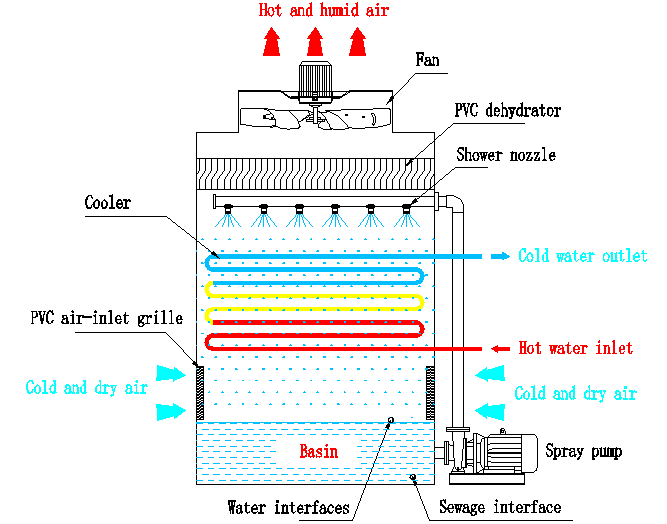

Counter Flow Closed Circuit Water Cooling Tower

for Air Compressor/Condition

Description

1.Cooldo brand closed cooling towers are Using the counter flow cooling way; few cooling blind area, high thermal efficiency:

2. Efficiency of cooling tower is to adopt the professional and efficient water collector to control the running floating rate ,that is less or equal to 0.001%;

3.Closed cooling tower in high air duct design to make sure the equipment to meet the demand of cooling air flow rate during operation;

4. Reduce the occupied area compare to other types of cooling tower to meet the users' space demanding;

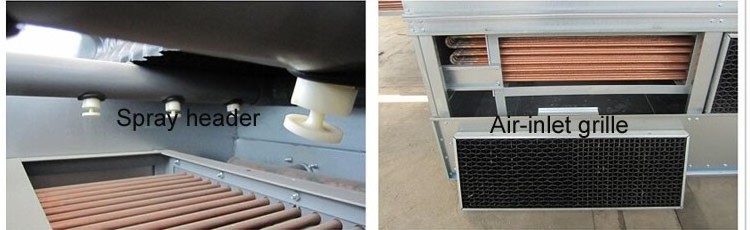

5.The tank of cooling tower adopts closed loop, eliminate clutters go into the tower body to produce spraying blocked;

6.The important part of counterflow cooling tower is the cooler that uses the antifreeze energy-saving design, to ensure the circulating water drain up and avoid freezing in the northern region with low temperature;

7.Design two-circuit cycle according to the demands of custom's devices, even if one circulation failure, anther cycle can be still normally operating;

8.The cooling tower design of units are elegant appearance, automatic digital display, easy to maintain.

Main Features

Water Cooling TowerMainly used in casting/foound field, forging/smithing field, heat treatment fieldand machinery cooling

● Fully enclosed circulating cooling, eliminate the pipeline jams caused by debris.

● Use soft water circulating cooling; no overheat damage of power supply, silicon control, capacitor, IGBT

module, induction coil caused by incrustation.

● No need of water pool and cooling tower, occupies small area, and moves easily.

● High cooling efficiency and low operate cost.

● Low water consumption, meet requirement of environment protection.