- Product Details

- {{item.text}}

Quick Details

-

Insulation Material:

-

Enameled

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

OUKEPU

-

Model Number:

-

Enameled wire

-

Round wire:

-

0.2-6.0mm

-

Thermal Class:

-

155-220C

-

Layer:

-

dual layer

-

Stardand:

-

IEC, NEMA, GB, JIS

-

Delivery time:

-

2-4 weeks

-

Function:

-

Coil winding wire

-

Testing:

-

breakdown voltage,peel off, sudden jerk.

Quick Details

-

Application:

-

used in motor ,transformer

-

Conductor Material:

-

Aluminum

-

Conductor Type:

-

Solid

-

Insulation Material:

-

Enameled

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

OUKEPU

-

Model Number:

-

Enameled wire

-

Round wire:

-

0.2-6.0mm

-

Thermal Class:

-

155-220C

-

Layer:

-

dual layer

-

Stardand:

-

IEC, NEMA, GB, JIS

-

Delivery time:

-

2-4 weeks

-

Function:

-

Coil winding wire

-

Testing:

-

breakdown voltage,peel off, sudden jerk.

Widely used in electrical motor armature enameled copper winding wire

1 . Process of producing

We can producing all the sizes in following :

|

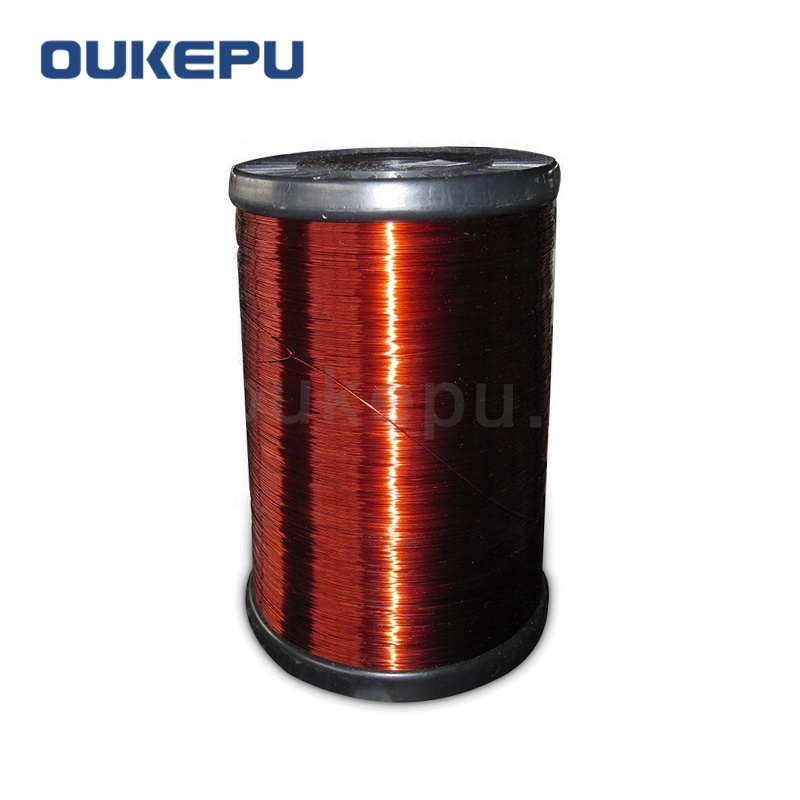

Enameled round aluminum wire

|

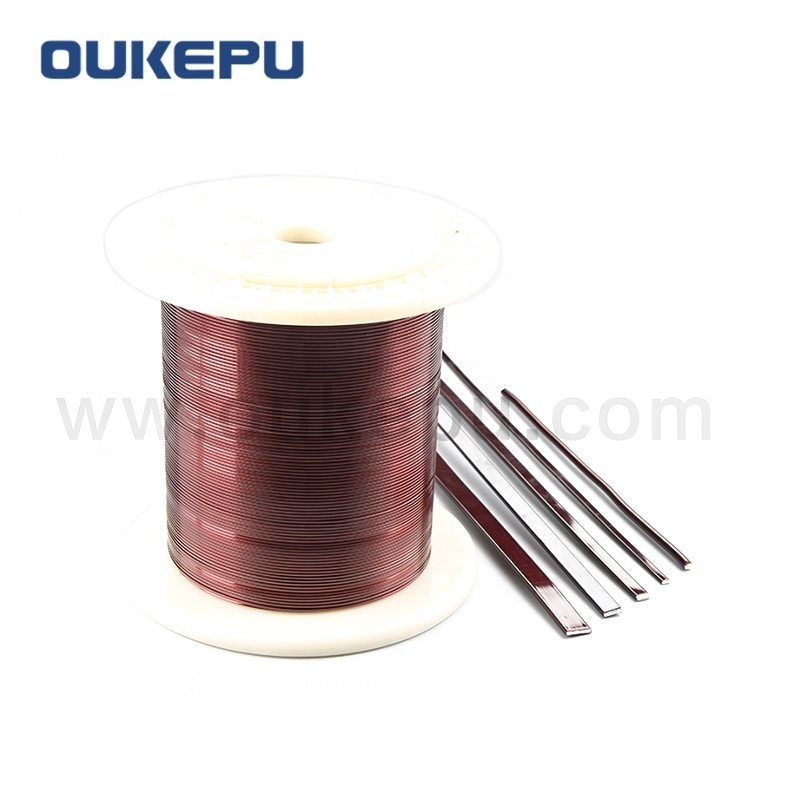

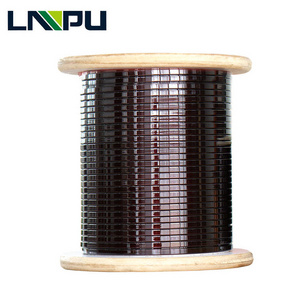

Enameled flat aluminum wire

|

|

Enameled round copper wire

|

Enameled flat copper wire

|

|

Non Woven Cloth/ Polyester Film covered wire

|

Polyimide Film Wrapped wire

|

|

Film Wrapped enameled wire

|

NOMEX Paper covered wire

|

|

Fiberglass Film Wrapped wire

|

Kraft Paper Wrapped wire

|

ouwei electric has a professional team to guarantee quality .

2. Process of Producing & Testing

Maximum Overall Diameter, Conductor Diameter, Film Thickness, Conductor Resistance, Elongation, Spring Back, Mandrel Winding, Sudden Jerk, Cut Through, Heat Shock, Room Temperature Breakdown Voltage, High Voltage Hole, and Pin-Hole, etc.

| Code Number | Test Standard | GB/T23312-7-2009 | |

| Size | 2.0mm | Date | |

| Type Q(ZY/XY)L-240 polyesterimide coated with polyamideimide | |||

| Test Tens | Standard value | Test Result | |

| Size | Maximum | 2.112mm | 2.095mm |

| Conductor Diameter | 2.00mm | 2.012mm | |

| Tolerance Value | ±0.020mm | 0.012mm | |

| F Result | ≤0.020mm | 0.001mm | |

| Film Thickness | ≥0.075mm | 0.083mm | |

| 20°C Resistivity | 0.008698-0.009149Ω/m | 0.00903-Ω/m | |

| Elongation | ≥15% | 32.20% | |

| Adherence | Test Axis Around | Winding ID | OK |

| Flexibility | Sudden/Pull | ≥55R | 65R |

| Anti-Solvent | ≥1h | 2h | |

| Alt-Throngh | 320°C,2min | OK | |

| Hot Shock | 240°C,30min | OK | |

| Broken Down Voltage Will Room | ≥5.0KV | 11.3/9.7/12/11.5/kv | |

| Continuity | High Voltage Hole | / | / |

| Pin-Hole | ≤5pcs/6m | 1pcs | |

| Conculusion | OK | ||