- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

customer demand

-

Dimension(L*W*H):

-

3560*1350*1800mm

-

Power (kW):

-

20

-

Weight (KG):

-

8500 KG

-

design temp:

-

170℃

-

thickness:

-

12mm

-

olled automatically Type::

-

Automatic and semi-automatic

-

Advantage::

-

differential pressure can be design

-

Power(W)::

-

65kw

-

heating way:

-

electric,steam

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CGY

-

Marketing Type:

-

New Product 2022

-

Voltage:

-

customer demand

-

Dimension(L*W*H):

-

3560*1350*1800mm

-

Power (kW):

-

20

-

Weight (KG):

-

8500 KG

-

design temp:

-

170℃

-

thickness:

-

12mm

-

olled automatically Type::

-

Automatic and semi-automatic

-

Advantage::

-

differential pressure can be design

-

Power(W)::

-

65kw

-

heating way:

-

electric,steam

Manufacturer supply rubber cold tire retreading equipment tyre repair machine

Note: We can design the different size of machine according to the requests for products.

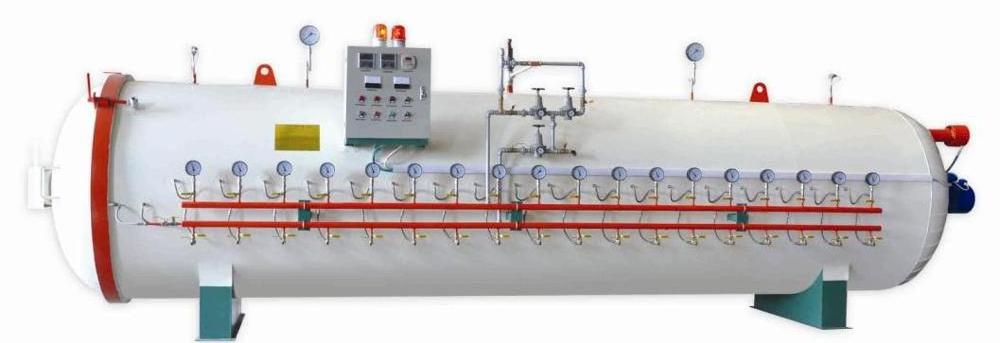

Cold tyre retreading equipment for tire recapping

1. Gerneral Specification

|

Specification |

16 pcs Curing Chamber for Truck Tyre |

|

Range of Tyre Size |

Within Size of 12.00-24 Truck and Passage Bus Tyre |

|

Operating Worker No |

Min. 4Staff(6 staff better) |

|

Workshop Area |

Min. 350m2 |

|

Curing Time |

220Minutes/per shift(Timing at 112°C) |

|

Max Daily Work Shift |

4ps/day |

|

Max Daily Output |

64 pcs/day for within ruled max size tyre |

|

Min Required Power |

380V,50HZ.,80KW |

|

Min Required Air Supply |

0.8Mpa |

|

Min Air Compressor |

1pcs(Air Displacement:1.5m3/min; Work Prssure:1.20Mpa;Auto Power:11KW |

|

Min Required Air Storage |

1pc(Storage Volume:1M3; Work Prssure:1.25Mpa;Temperature:100°C) |

2.Function Description

a.Suitable for double-envelope curing, rim&tube curing and envelope-sealing ring curing

b.Display the curing parameters and the working state of kay components

c.Alarm when fault happens also has fault analysis

d.Adopt isolation transformer to keep PLC work smoothly

e.Heating tube heat alternately when start curing,maintain temperature balance

d.Optional Tire size:5"-15", 15"-22.5", 22.5"-25", 25"-33".

Can be designed according to your output.

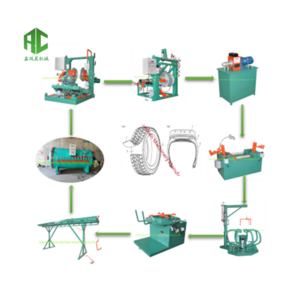

3.The process as follow

tyre clean firstly dry tyre → inspecting tyre → buffing tyre → buffing outer wound of tyre → buffing inner wound of tyre → secondly inspecting tyre → repair inner wound → brushing adhesive on roof of tyre → secondly drying tyre → repair outer wound → affix middle rubber piece → tread building →assemble envelop → assemble inner tyre → assemble curing rim → inspecting inner tyre and curing rim → curing→ disassemble curing rim→ disassemble inner tyre → disassemble envelop → inspect end product → embellish tyre→ store tyre.

4, Equipment List:

the tyre retreading production line contains the following equipment:

* standard (necessery)

2. inflatable tyre grinding machine

3. rubber powder collecting tank

4. inflatable tread pressing machine

6. envolop disassembly machine

8. rubber cement mixing tank

9. multifunctional tire repairing machine

10. circular gulding rail frame

11. hanging hook

* Optional Equipment

1. expansion tire for testing machine

2. tyre repair and cutting machine

3. tyre repair frame

Tyre before and after retreading:

Process show:

Main Market: Europe, South Asia, USA, South America, Middle East etc

For curing chamber:

1.supply truck tire and OTR tire type.

2.supply automatic and semi-automatic type .

3.capacity:6tires,8tires,12tires,16tires,22tires and 25tires or according to your requirements.

For complete plant:

1.design equipments and rail system for you

2.training for free

3.installation for free

4.Remote diagnosis&analysis

5.Warranty:24 months

6.We can also supply precure tread rubber with superior quality and best price.

Our company-Qingdao Guangyue Rubber Machinery Manufacturing Co., Ltd entered tire retreading

industry in the early 1990s. Starting from tire retreading services,then tread rubber&tire

retreading equipments production and then franchisees, now we have covered the

whole chain. Waiting for your visit and equiry!

Workshop for training

Workshop for equipment production