- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

1000

-

Spindle Taper:

-

HSK-A63

-

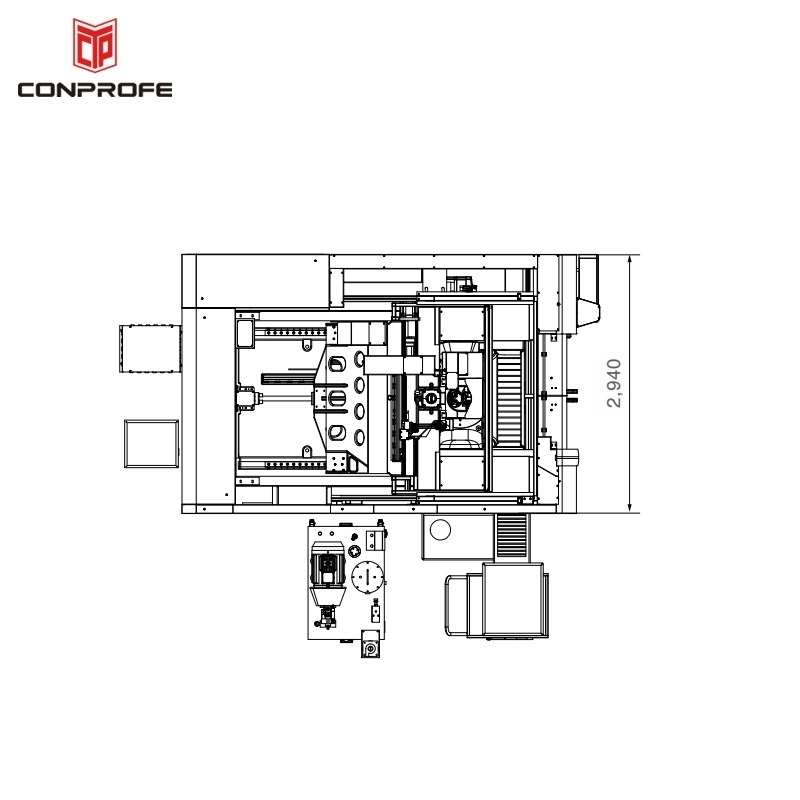

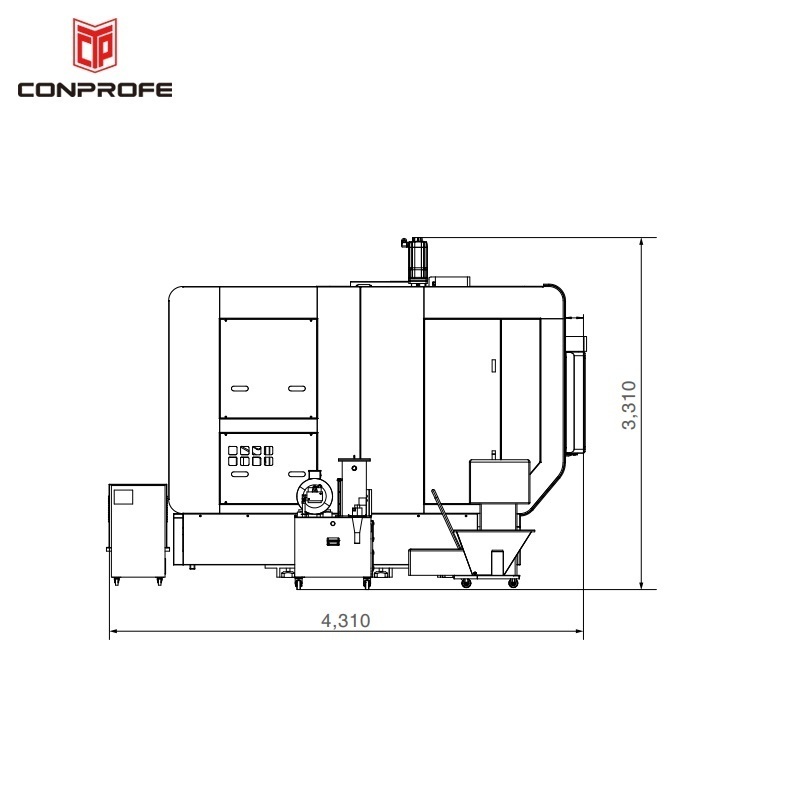

Dimension(L*W*H):

-

2,940*4,310*3,310mm

-

Weight (T):

-

16.5 T

-

Spindle Motor Power(kW):

-

/

-

Max. Table Load(kg):

-

800 kg

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CONPROFE

-

Voltage:

-

Three-phase AC, 380V/50Hz

-

Product name:

-

Ultrasonic Vertical 5-Axis Machining Center

-

Max. Tool Length:

-

300mm

-

Required Air Pressure:

-

0.5-0.7MPa

-

Total Air Consumption:

-

>100 L/min

-

X/Y/Z Axis Rapid Speed:

-

36/36/30 m/min

-

A/C Axis Rapid Speed:

-

30/70 rpm

-

T-slot (No. x Width):

-

8-18pcs*H8mm

-

A/C Positioning Accuracy:

-

8''

-

A/C Axis Repeatability Accuracy:

-

5''

-

Speed (Max.):

-

14,000 rpm

Quick Details

-

Table Size (mm):

-

D650*450

-

Number of Axes:

-

5

-

Table Travel (X) (mm):

-

800

-

Table Travel (Y) (mm):

-

1000

-

Spindle Taper:

-

HSK-A63

-

Dimension(L*W*H):

-

2,940*4,310*3,310mm

-

Weight (T):

-

16.5 T

-

Spindle Motor Power(kW):

-

/

-

Max. Table Load(kg):

-

800 kg

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CONPROFE

-

Voltage:

-

Three-phase AC, 380V/50Hz

-

Product name:

-

Ultrasonic Vertical 5-Axis Machining Center

-

Max. Tool Length:

-

300mm

-

Required Air Pressure:

-

0.5-0.7MPa

-

Total Air Consumption:

-

>100 L/min

-

X/Y/Z Axis Rapid Speed:

-

36/36/30 m/min

-

A/C Axis Rapid Speed:

-

30/70 rpm

-

T-slot (No. x Width):

-

8-18pcs*H8mm

-

A/C Positioning Accuracy:

-

8''

-

A/C Axis Repeatability Accuracy:

-

5''

-

Speed (Max.):

-

14,000 rpm

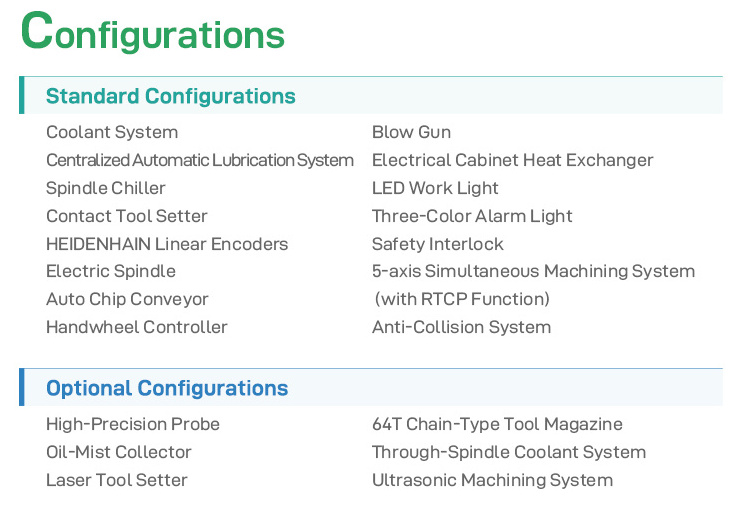

Vertical 5-Axis Simultaneous Machining Center SPV Series

Conprofe Vertical

5-Axis Simultaneous Machining Center SPV Series

can meet the five-axis simultaneous machining needs of different sizes of parts, with high speed, high precision, high rigidity and other performance advantages; a single machine tool can complete multiple processes of compound machining to achieve intensive production.

The whole machine bed adopts cast iron material with excellent shock absorption performance, which has extremely high dynamic cutting performance, stability and reliability, and strong applicability.

Integrating ultrasonic technology with independent intellectual property rights, it can machine hard and brittle materials (ceramics, sapphire, glass, carbon fiber composite materials, etc.) and difficult-to-cut materials with better surface quality,longer tool life, and higher machining efficiency. Browse high quality with the best 5-Axis machining center with 5 axis cnc milling machine price below.

The whole machine bed adopts cast iron material with excellent shock absorption performance, which has extremely high dynamic cutting performance, stability and reliability, and strong applicability.

Integrating ultrasonic technology with independent intellectual property rights, it can machine hard and brittle materials (ceramics, sapphire, glass, carbon fiber composite materials, etc.) and difficult-to-cut materials with better surface quality,longer tool life, and higher machining efficiency. Browse high quality with the best 5-Axis machining center with 5 axis cnc milling machine price below.

Product Description

|

Parameters

|

|

|

|

|

|

|||||

|

Item

|

Unit

|

SPV200-5AXIS

|

SPV400-5AXIS

|

SPV500-5AXIS

|

SPV650-5AXIS

|

|||||

|

Travel

|

|

|

|

|

|

|||||

|

X/Y/Z-Axis Travel

|

mm

|

280x580x280

|

420x800x380

|

500×550×500

|

800×1,000×550

|

|||||

|

A/C-Axis Swivel Range

|

°

|

±120/360

|

±120/360

|

±120/360

|

±100/360

|

|||||

|

Worktable

|

|

|

|

|

|

|||||

|

Dimensions

|

mm

|

Φ200

|

Φ400

|

Φ500

|

Φ650

|

|||||

|

Max. Load

|

kg

|

30

|

200

|

300

|

800

|

|||||

|

T-Slot (No. x Width)

|

Pcsxmm

|

4-14H8

|

8-1H28

|

8-14H8

|

8-18H8

|

|||||

|

Max. Workpiece Size

|

mm

|

Φ200x190

|

Φ455x260

|

Φ500x400

|

Φ650x450

|

|||||

|

Spindle

|

|

|

|

|

|

|||||

|

Diameter

|

mm

|

Φ100

|

Φ155

|

Φ190

|

Φ190

|

|||||

|

Max. Speed (Short-Duration)

|

rmp

|

30,000

|

20,000

|

20,000

|

20,000

|

|||||

|

Max. Speed (Long-Duration)

|

rmp

|

25,000

|

16,000

|

14,000

|

14,000

|

|||||

|

Spindle Taper

|

-

|

HSK-E32

|

HSK-A63

|

HSK-A63

|

HSK-A63

|

|||||

|

Motor Power

|

kW

|

6

|

22

|

35

|

35

|

|||||

|

Motor Torque

|

Nm

|

2.7

|

29.2

|

85

|

85

|

|||||

|

Ultrasonic

|

-

|

/

|

/

|

/

|

/

|

|||||

|

Feed Rate

|

|

|

|

|

|

|||||

|

X/Y/Z-Axis Rapid Speed

|

m/min

|

36/36/36

|

36/36/36

|

36/36/30

|

36/36/30

|

|||||

|

A/C-Axis Rapid Speed

|

rmp

|

100/200

|

100/150

|

50/100

|

30/70

|

|||||

|

Accuracy

|

|

|

|

|

|

|||||

|

X/Y/Z-Axis Positioning Accuracy

|

mm

|

0.007

|

0.007

|

0.007

|

0.008

|

|||||

|

X/Y/Z-Axis Repeatability

|

mm

|

0.004

|

0.004

|

0.004

|

0.005

|

|||||

|

A/C-Axis Positioning Accuracy

|

”

|

8

|

8

|

8

|

8

|

|||||

|

A/C-Axis Repeatability

|

”

|

4

|

4

|

5

|

5

|

|||||

|

Tool Magazine

|

|

|

|

|

|

|||||

|

Tool Holding Capacity

|

No. of Tools

|

40

|

40

|

24

|

40

|

|||||

|

Max. Tool Diameter (Full)

|

mm

|

Φ50

|

Φ70

|

Φ75

|

Φ75

|

|||||

|

Max. Tool Length

|

mm

|

200

|

200

|

300

|

300

|

|||||

|

Max. Tool Weight

|

kg

|

5

|

8

|

8

|

8

|

|||||

|

Type

|

-

|

Chain Type

|

Chain Type

|

Umbrella Type

|

Chain Type

|

|||||

|

Miscellaneous

|

|

|

|

|

|

|||||

|

Power Supply Voltage

|

-

|

Three-Phase AC, 380V/50Hz

|

Three-Phase AC, 380V/50Hz

|

Three-Phase AC, 380V/50Hz

|

Three-Phase AC, 380V/50Hz

|

|||||

|

Power Capacity

|

kVA

|

16

|

30

|

60

|

110

|

|||||

|

Air Pressure

|

MPa

|

0.5-0.7

|

0.5-0.7

|

0.5-0.7

|

0.5-0.7

|

|||||

|

Total Air Consumption

|

L/min

|

>60

|

>100

|

>100

|

>100

|

|||||

|

Total Weight (incl. Accessories)

|

kg

|

4,000

|

7,000

|

10,000

|

16,500

|

|||||

|

Machine Size (LxWxH)

|

mm

|

1,600x2,700x2,080

|

2,000x3,310x2,420

|

2,240x3,780x2,855

|

2,940x4,310x3,310

|

|||||

|

Controller

|

|

|

|

|

|

|||||

|

CNC Controller

|

-

|

SIEMENS 840D sl (Standard)

|

|

|

|

|||||

|

|

|

HEIDENHAIN/HNC (Optional)

|

|

|

|

|||||

|

Parameters

|

|

|

|

|

||||

|

Item

|

Unit

|

SPV800-5AXIS

|

SPV1000-5AXIS

|

SPV1250-5AXIS

|

||||

|

Travel

|

|

|

|

|

||||

|

X/Y/Z-Axis Travel

|

mm

|

800×1000×550

|

1,250×1,250×1,000

|

1,250×1,250×1,000

|

||||

|

A/C-Axis Swivel Range

|

°

|

±100/360

|

±100/360

|

±100/360

|

||||

|

Worktable

|

|

|

|

|

||||

|

Dimensions

|

mm

|

Φ800

|

Φ1,000

|

Φ1,200

|

||||

|

Max. Load

|

kg

|

900

|

1,000

|

1,000

|

||||

|

T-Slot (No. x Width)

|

Pcsxmm

|

8-18H8

|

8-18H8

|

8-18H8

|

||||

|

Max. Workpiece Size

|

mm

|

Φ800x500

|

Φ1,000x500

|

Φ1,200x500

|

||||

|

Spindle

|

|

|

|

|

||||

|

Diameter

|

mm

|

Φ190

|

Φ210

|

Φ210

|

||||

|

Max. Speed (Short-Duration)

|

rmp

|

20,000

|

12,000

|

12,000

|

||||

|

Max. Speed (Long-Duration)

|

rmp

|

14,000

|

10,000

|

10,000

|

||||

|

Spindle Taper

|

-

|

HSK-A63

|

HSK-A100

|

HSK-A100

|

||||

|

Motor Power

|

kW

|

35

|

26

|

26

|

||||

|

Motor Torque

|

Nm

|

85

|

161

|

161

|

||||

|

Ultrasonic

|

-

|

/

|

/

|

/

|

||||

|

Feed Rate

|

|

|

|

|

||||

|

X/Y/Z-Axis Rapid Speed

|

m/min

|

36/36/30

|

30/30/30

|

30/30/30

|

||||

|

A/C-Axis Rapid Speed

|

rmp

|

30/70

|

30/60

|

30/60

|

||||

|

Accuracy

|

|

|

|

|

||||

|

X/Y/Z-Axis Positioning Accuracy

|

mm

|

0.008

|

0.008

|

0.008

|

||||

|

X/Y/Z-Axis Repeatability

|

mm

|

0.005

|

0.005

|

0.005

|

||||

|

A/C-Axis Positioning Accuracy

|

”

|

8

|

15

|

15

|

||||

|

A/C-Axis Repeatability

|

”

|

5

|

8

|

8

|

||||

|

Tool Magazine

|

|

|

|

|

||||

|

Tool Holding Capacity

|

No. of Tools

|

40

|

40

|

40

|

||||

|

Max. Tool Diameter (Full)

|

mm

|

Φ75

|

Φ85

|

Φ85

|

||||

|

Max. Tool Length

|

mm

|

300

|

320

|

320

|

||||

|

Max. Tool Weight

|

kg

|

8

|

20

|

20

|

||||

|

Type

|

-

|

Chain Type

|

Chain Type

|

Chain Type

|

||||

|

Miscellaneous

|

|

|

|

|

||||

|

Power Supply Voltage

|

-

|

Three-Phase AC, 380V/50Hz

|

Three-Phase AC, 380V/50Hz

|

Three-Phase AC, 380V/50Hz

|

||||

|

Power Capacity

|

kVA

|

110

|

110

|

110

|

||||

|

Air Pressure

|

MPa

|

0.5-0.7

|

0.5-0.7

|

0.5-0.7

|

||||

|

Total Air Consumption

|

L/min

|

>100

|

>100

|

>100

|

||||

|

Total Weight (incl. Accessories)

|

kg

|

17,000

|

25,000

|

26,000

|

||||

|

Machine Size (LxWxH)

|

mm

|

2,940x4,310x3,310

|

3,400x4,350x4,220

|

3,400x4,350x4,220

|

||||

|

Controller

|

|

|

|

|

||||

|

CNC Controller

|

-

|

SIEMENS 840D sl (Standard)

|

|

|

||||

|

|

|

HEIDENHAIN/HNC (Optional)

|

|

|

||||

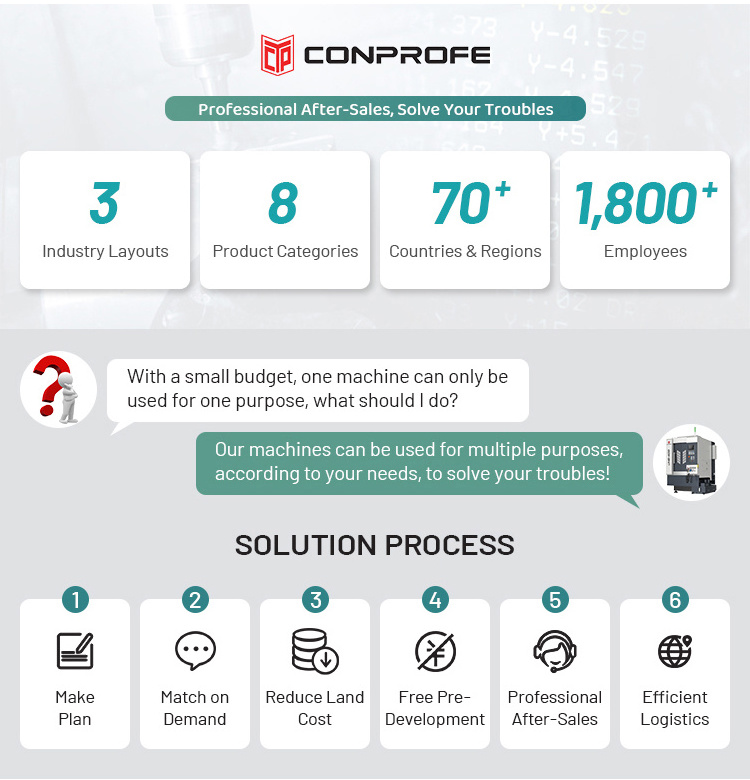

Overview

Intelligent Ultrasonic machining system developed by Conprofe to tackle the challenges in machining hard-to-cut materials

Supercritical Carbon Dioxide (ScCO2) Cryogenic Through-Spindle Cooling System and MQL Cooling System available for clean machining

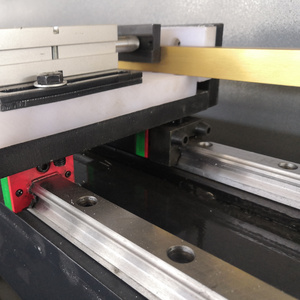

Bridge gantry structure with tilting 5th-axis rotary table; low center of gravity, short overhang, and super high rigidity for lower thermal strain

Equipped with high-power, high-torque, high-speed ultrasonic spindle

Various chain-type tool magazine capacity options: 24~120T

An automatic fire suppression system can be configured to reduce the risk of machining flammable and explosive materials

Siemens 840D sl and SINUMERIK ONE 5-axis Simultaneous control systems available

Ultrasonic Machining Advantages

Efficient processing of metals, hard & brittle materials

Cutting force down by 50%

Cutting heat down by 30%

Sub-surface damage reduced by 40%

Tool life improved by 3~10 times

Efficiency significantly increased by reducing C/T

Cutting force down by 50%

Cutting heat down by 30%

Sub-surface damage reduced by 40%

Tool life improved by 3~10 times

Efficiency significantly increased by reducing C/T

Best Sellers

Hot Searches