- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

3x1.6x1.8m

-

Weight:

-

2500 kgs

-

Web Width:

-

600mm

-

Color:

-

4 Color

-

Printing Speed:

-

50 m/min

-

Unwind/Rewind:

-

500 mm (3" Air Expanding Shaft)

-

Precision:

-

±0.4mm

-

Auto Counter:

-

Yes

-

Anilox Roller:

-

Metal or Ceramic

-

Product:

-

Plastic, paper, aluminum foil......

-

Name:

-

Non Woven Plastic Bag Printing Machine With Cheap Price For Sale

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Showroom Location:

-

None

-

After-sales Service Provided:

-

Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Marketing Type:

-

New Product 2019

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Ziye

-

Voltage:

-

380V/220V/415V/110V

-

Dimensions(L*W*H):

-

3x1.6x1.8m

-

Weight:

-

2500 kgs

-

Web Width:

-

600mm

-

Color:

-

4 Color

-

Printing Speed:

-

50 m/min

-

Unwind/Rewind:

-

500 mm (3" Air Expanding Shaft)

-

Precision:

-

±0.4mm

-

Auto Counter:

-

Yes

-

Anilox Roller:

-

Metal or Ceramic

-

Product:

-

Plastic, paper, aluminum foil......

-

Name:

-

Non Woven Plastic Bag Printing Machine With Cheap Price For Sale

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Showroom Location:

-

None

-

After-sales Service Provided:

-

Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

Marketing Type:

-

New Product 2019

-

Certification:

-

CE

Product Description

F

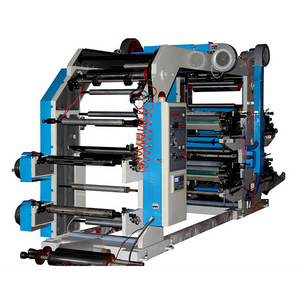

P4600 4 Color Fabric Non Woven Plastic Bag Printing Machine With Cheap Price For Sale

The machine can finish material-feeding,printing, drying, laminating, rewinding in one process is anideal machine for printing plastic film, paper and etc.

Feature:

1. Easy operation, gentle starting, accurate color print.

2. The meter counter can set print quantity according the requirements, stop the machine automatically at the quantity or when the material is cut off.

3. After lifting and lowering the printing plate cylinder manually, It will automatically stir the printing in.

4. The printing in is spread by the anilox cylinder roller with evenly ink.

5. Reliable dry system, coordinate high-speed operation, engine off automatic abruption.

6. 360 degrees continuously adjustable longitudinal to register device.

7. Frequency conversion velocity modulation, adaption different pointing speed.

8. On the version roller sear and receives on material to be loaded with the spot to move and the pause button, is advantage for when the justification operates the machine.

2. The meter counter can set print quantity according the requirements, stop the machine automatically at the quantity or when the material is cut off.

3. After lifting and lowering the printing plate cylinder manually, It will automatically stir the printing in.

4. The printing in is spread by the anilox cylinder roller with evenly ink.

5. Reliable dry system, coordinate high-speed operation, engine off automatic abruption.

6. 360 degrees continuously adjustable longitudinal to register device.

7. Frequency conversion velocity modulation, adaption different pointing speed.

8. On the version roller sear and receives on material to be loaded with the spot to move and the pause button, is advantage for when the justification operates the machine.

Samples

Plastic Films (PVC, PP, PET...)

All kinds of Paper (below 250gsm)

Non Woven Fabric

Product Paramenters

|

Machine Model

|

FP4600

|

FP4800

|

FP41000

|

|

Printing speed

|

50m/min

|

50m/min

|

50m/min

|

|

Max. Web Width

|

600mm

|

800mm

|

1000mm

|

|

Max. Unwinding/Rewind Diameter

|

500mm

|

500mm

|

500mm

|

|

Printing Length

|

191-1000mm

|

191-1000mm

|

191-1000mm

|

|

Color Quantity

|

4 colors

|

4 colors

|

4 colors

|

|

Dimensions

|

4300*1600*2445mm

|

4300*1800*2445mm

|

4300*2000*2445mm

|

|

Main motor

|

15 KW

|

15 KW

|

15 KW

|

|

Voltage

|

220V/380V

|

220V/380V

|

220V/380V

|

|

Gear

|

Straight/Helical Gear

|

Straight/Helical Gear

|

Straight/Helical Gear

|

|

Machine weight

|

2500 kgs

|

3000 kgs

|

3500 kgs

|

Details Images

Flexo Printing Unit

Printing Station Comes with Ink Rubber Roller, Anilox Cylinder, Printing Plate Cylinde and Ink Container.

Unwind Unit

With 1 pc 3" Air Expanding Shaft, Can accept max diameter 500mm material jumbo roll. (can be customized)

Rewind

With 2 pc 3" Air Expanding Shaft,

Can accept max diameter 500mm material jumbo roll. (can be customized)

Web Guide System

Control paper move straightly.(Optional)

Magnetic Brake and Clutch

With One 50 N.M Magnetic Brake, Two 50 N.M Magnetic Clutch (Optional)

Auto Constant Tension Controller

With 2 Set Auto Constant Tension Controller For Unwind and Rewind

(Optional)

Heating & Drying Unit

1).Each Printing Unit comes with Heating Drying Oven.

2).Infrared Heating Drying Oven is placed on material and after each printing station.

2).Infrared Heating Drying Oven is placed on material and after each printing station.

Gear Driving System

Machine Drive By Straight/Helical Gear(Optional). Low Noise and Stable Operation

Control Panel

1).Power Supply, Stop Button, Start Button and Emergency Stop.

2).Anilox Roller Rotation Button for each Printing Station.

Length Counter and Speed Controller

2).Anilox Roller Rotation Button for each Printing Station.

Length Counter and Speed Controller

Hot Searches